Photoelectric switch chip production device and method

A photoelectric switch and chip technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of reduced chip production and processing efficiency, reduced silicon wafer cleaning effect, and secondary pollution on the silicon wafer surface, so as to improve transmission and absorption Efficiency, simplified packaging process, simplified processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

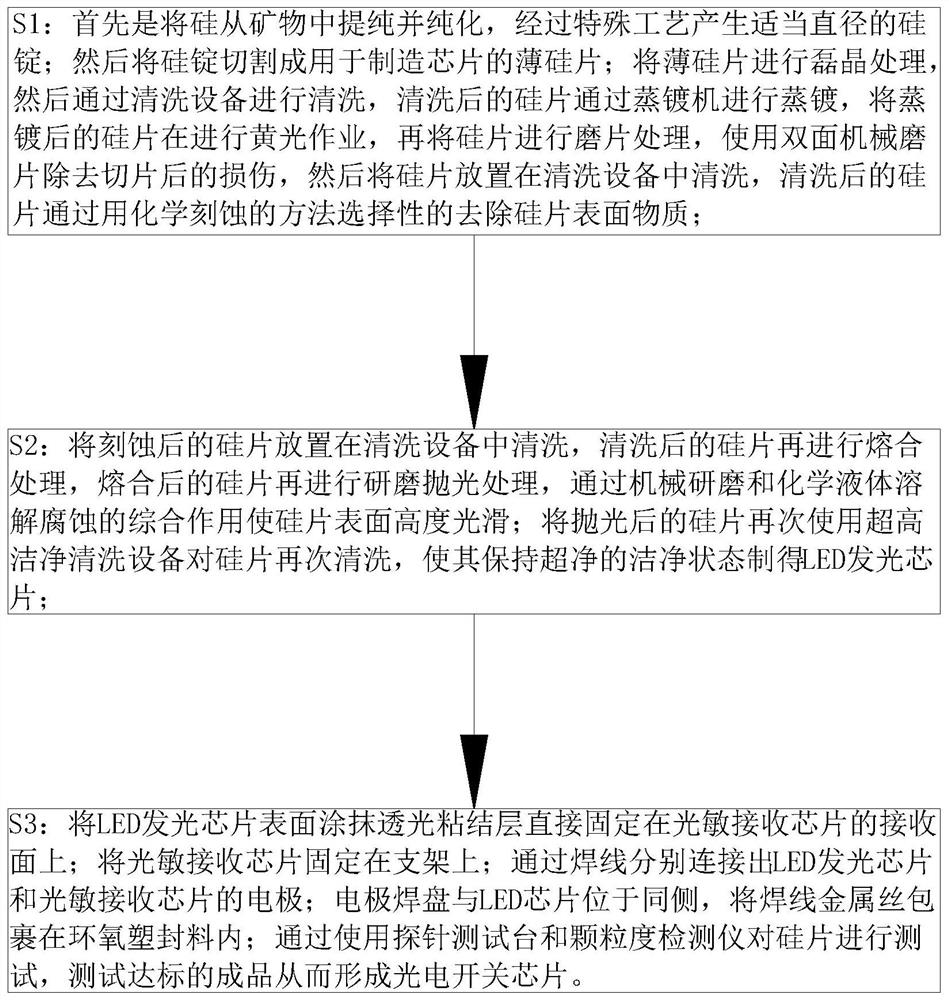

Method used

Image

Examples

Embodiment approach

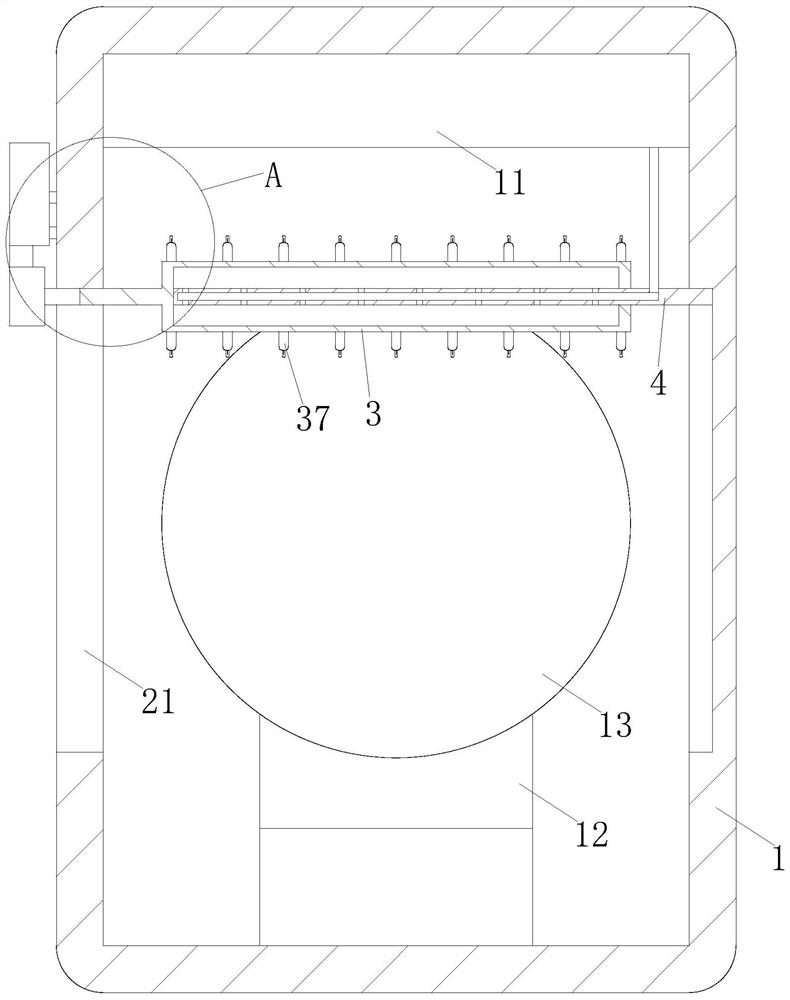

[0036] As an embodiment of the present invention, the second hole 32 is a tapered hole, and the diameter of the second hole 32 close to the fixed shaft 4 is larger than the diameter of the second hole 32 away from the fixed shaft 4 .

[0037] When in use, the rotating tube 3 drives the No. 3 plate 36 to move, and the end of the No. 3 plate 36 close to the fixed shaft 4 is attached to the surface of the rotating tube 3. The No. 3 plate 36 moves until it touches the No. 2 plate 34 and pushes the No. 2 plate 34 to move. The third plate 36 pushes the second plate 34 to move with the fixed shaft 4 as the center of circle, and the third plate 36 squeezes the cleaning liquid between the second plate 34 and the third plate 36 in the rotating tube 3, and the cleaning liquid is affected by gravity and the second plate 36. Under the extrusion force produced between the No. plate 34 and the No. three plate 36, the cleaning liquid flows out through the No. 2 hole 32. Since the No. 2 hole 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com