Oil cooling driving motor and automobile

A technology for driving motors and oil cooling, which is applied in the directions of electromechanical devices, electrical components, and electric components, etc., can solve the problem of unbalanced heat dissipation of motors, and achieve the effect of improving temperature field distribution, improving output capacity, and uniform temperature field distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

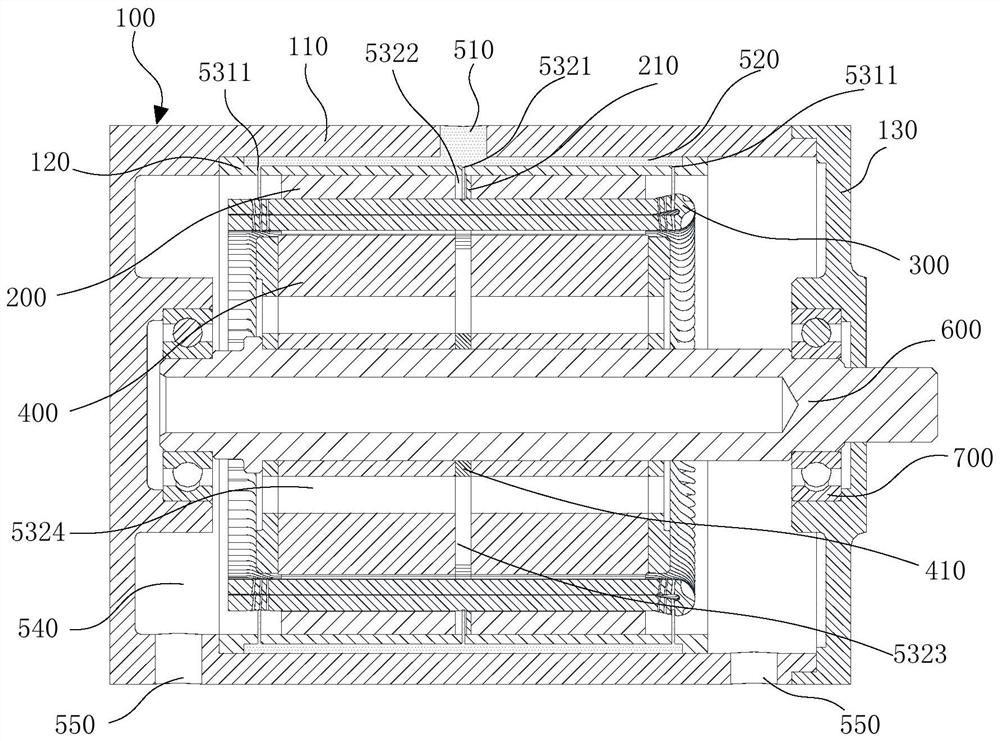

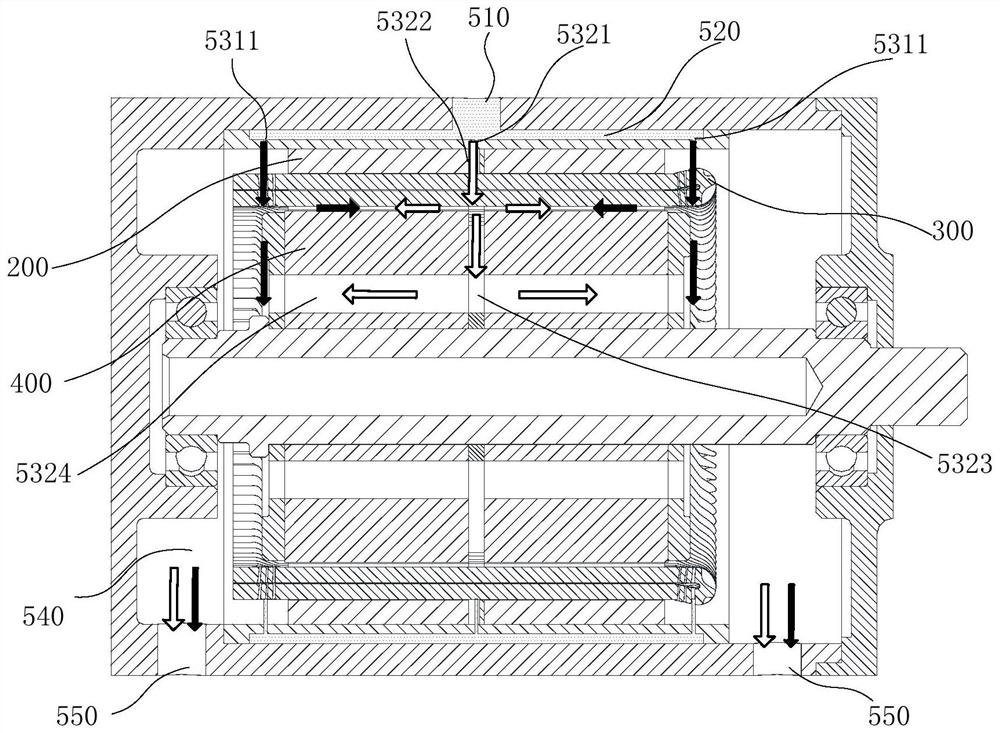

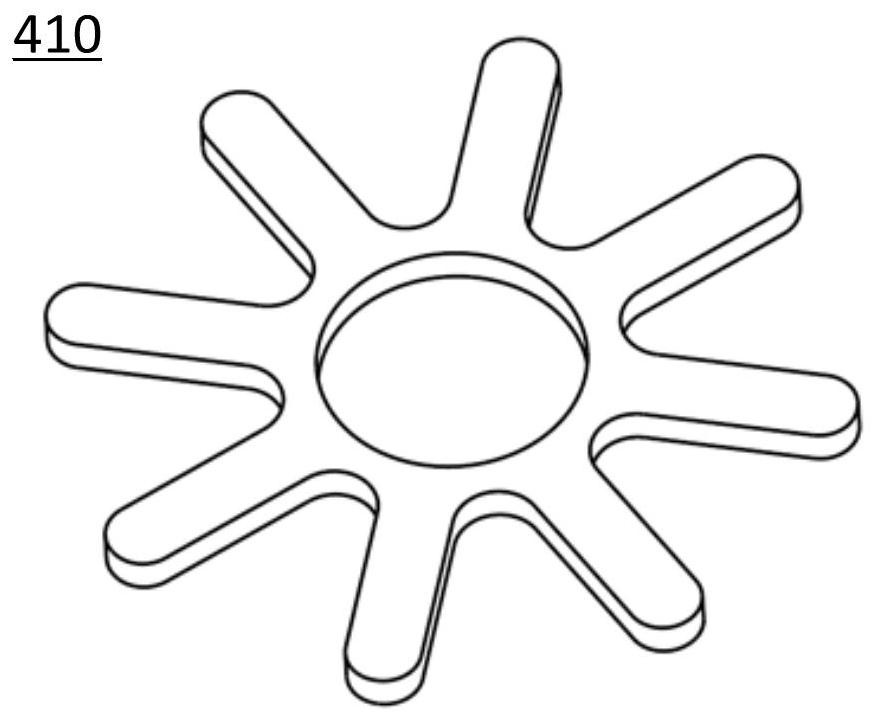

[0054] The present invention provides an oil-cooled drive motor, such as figure 1 As shown, it includes a housing 100, a stator core 200, a stator winding coil 300, and a rotor core 400 arranged sequentially from outside to inside, and a gap is formed between the inner wall surface of the stator winding coil 300 and the outer wall surface of the rotor core 400, And the two ends of the stator core 200 are respectively close to the two ends of the stator winding coil 300 , the two ends of the rotor core 400 are respectively close to the two ends of the stator winding coil 300 , and the oil-cooled drive motor also includes an oil cooling system 500 .

[0055] The oil-cooled drive motor also includes at least one stator separator 210 and at least one rotor separator 310; at least one stator separator 210 divides the stator core 200 into at least two sections of the stator core 200 along the axial direction of the stator core 200, and A stator separator 210 is fixed between any two...

Embodiment 2

[0083] The present invention also provides an automobile, including the oil-cooled drive motor provided in Embodiment 1.

[0084] By adopting the above solution, the temperature field distribution of the motor used in the automobile is more uniform, thereby improving the output capability of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com