Apparatus for generating chlorine disinfectant

A generation device and chlorine disinfection technology, which is applied in water/sewage treatment, water treatment parameter control, water/sewage treatment equipment, etc., can solve the problems of product production cost increase, concentration reduction, sodium hypochlorite inconvenience, etc., to save production costs, Improvement of working time and working capacity and improvement of electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

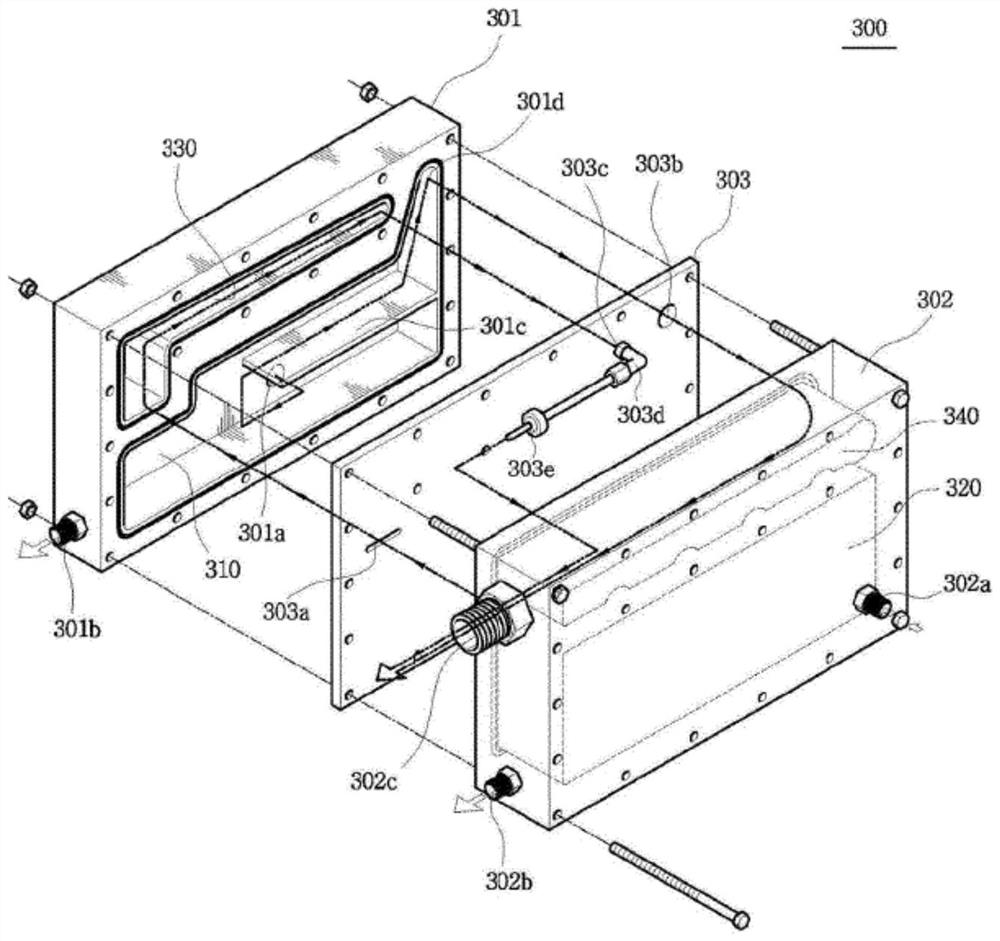

[0062] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

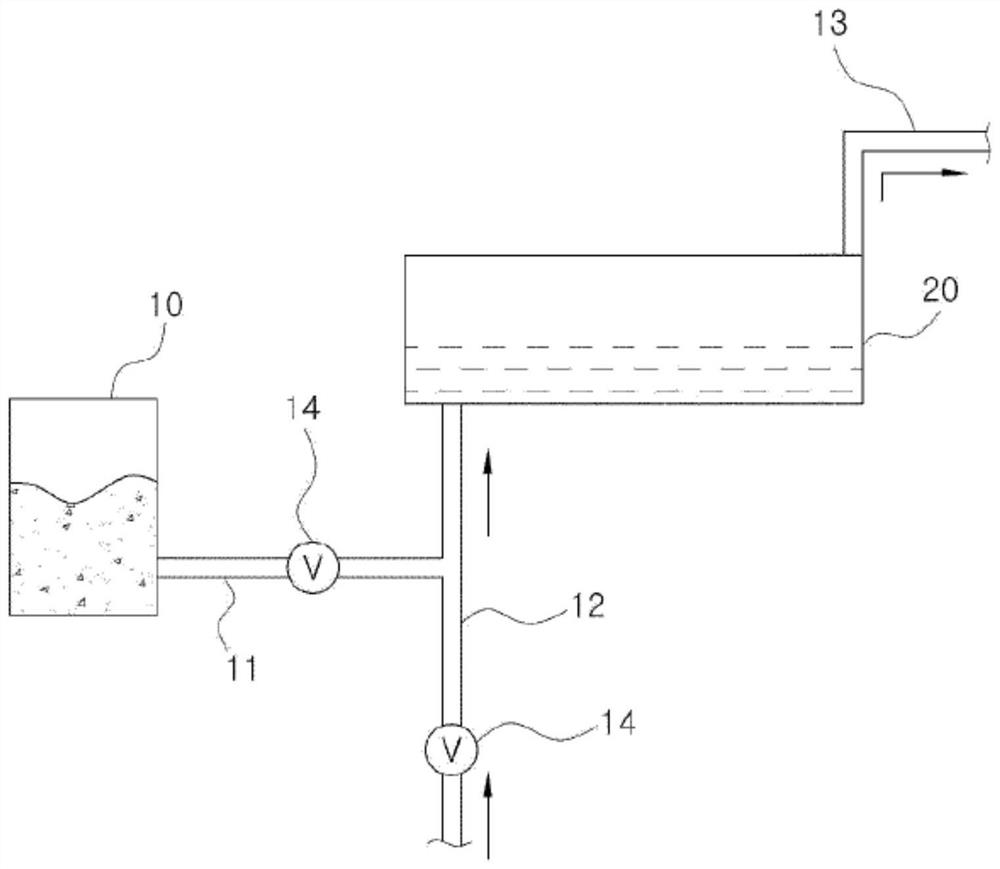

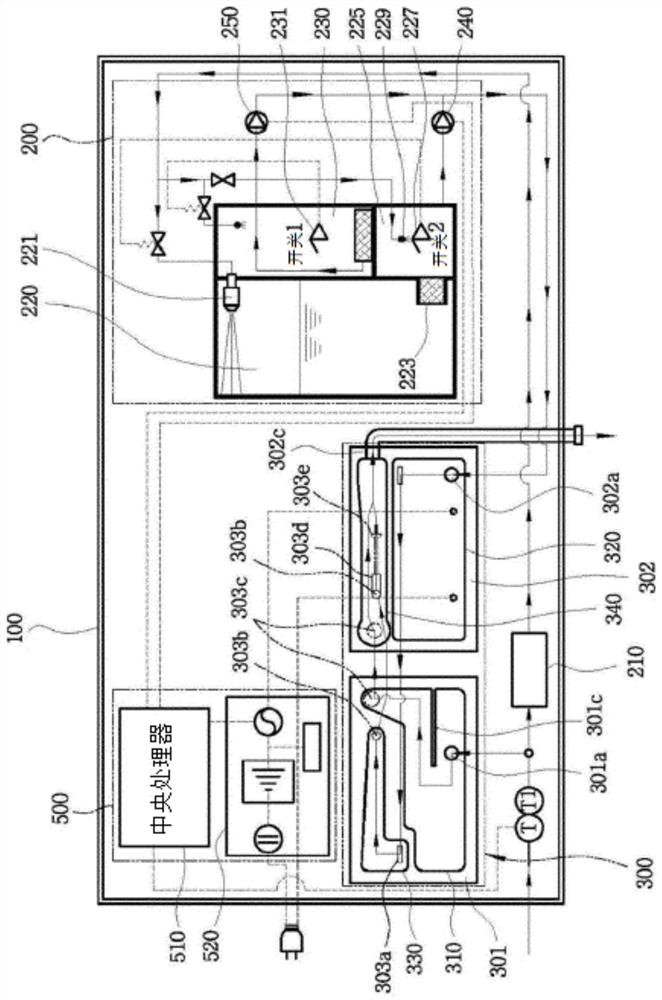

[0063] figure 2 It is a schematic configuration diagram of the chlorine disinfection water generator according to the present invention.

[0064] refer to figure 2 , discloses a chlorine disinfection water generation device, which arranges a brine supply part 200, a hypochlorine generation part 300 and a control part 500 in a main body box 100, and the brine supply part 200 is mixed and introduced in a certain proportion in a piping line supplying saturated brine water to generate diluted brine, the hypochlorite generating unit 300 receives the supply of diluted brine and undergoes an electrolysis process to generate sodium hypochlorite, and mixes the sodium hypochlorite into the water in a desired ratio to generate chlorine disinfection water. The control unit 500 controls the brine supply unit 200 and the hypochlorine generation un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com