Plant disinfectant and preparation method thereof

A disinfectant and plant technology, applied in botany equipment and methods, disinfectants, plant growth regulators, etc., to achieve good sterilization and disinfection effects, good stability, and significant synergistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

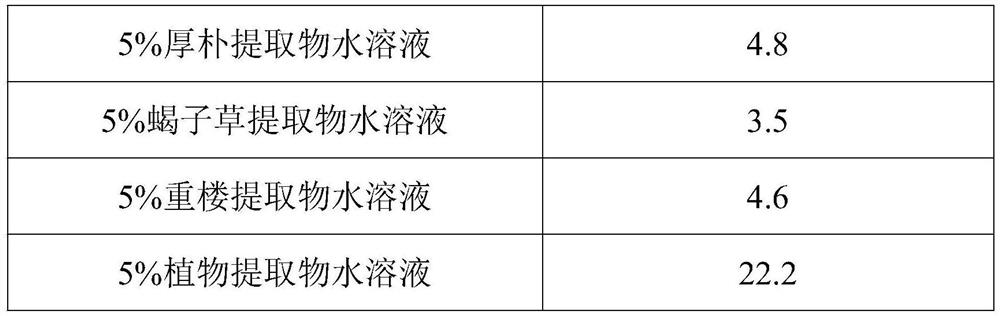

[0044] A plant disinfectant solution prepared from the following raw materials in parts by weight: 1.6 parts of plant extract, 3 parts of stabilizer, 5 parts of isopropanol, and 90.4 parts of deionized water.

[0045] The plant extract is composed of 6 parts by weight of Magnolia officinalis extract, 5 parts by weight of Scorpion grass extract and 5 parts by weight of Chonglou extract.

[0046] The stabilizer is composed of 2 parts by weight of sucrose, 3 parts by weight of calcium dihydrogen phosphate, and 5 parts by weight of sodium alginate.

[0047]The preparation method of described Magnolia officinalis extract is:

[0048] S01, washing Magnolia officinalis medicinal material, drying, pulverizing to 80 mesh, obtaining Magnolia officinalis powder;

[0049] S02. Add Magnolia officinalis powder into deionized water, extract at 70°C for 50 minutes to obtain Magnolia officinalis extract, the ratio of Magnolia officinalis powder to deionized water is 1g:10ml;

[0050] S03. Ad...

Embodiment 2

[0069] A plant disinfectant, prepared from the following raw materials in parts by weight: 1 part of plant extract, 3 parts of stabilizer, 4 parts of isopropanol, and 92 parts of deionized water;

[0070] The plant extract is composed of 5 parts by weight of Magnolia officinalis extract, 3 parts by weight of Scorpion grass extract, and 2 parts by weight of Chonglou extract.

[0071] The stabilizer is composed of 2 parts by weight of sucrose, 4 parts by weight of calcium dihydrogen phosphate, and 4 parts by weight of sodium alginate.

[0072] The preparation method of described Magnolia officinalis extract is:

[0073] S01, washing Magnolia officinalis medicinal material, drying, pulverizing to 80 mesh, obtaining Magnolia officinalis powder;

[0074] S02. Add Magnolia officinalis powder into deionized water, extract at 65°C for 50 minutes to obtain Magnolia officinalis extract, the ratio of Magnolia officinalis powder to deionized water is 1g:9ml;

[0075] S03. Add the mixed ...

Embodiment 3

[0094] A plant disinfectant, prepared from the following raw materials in parts by weight: 1.5 parts of plant extracts, 3.2 parts of stabilizers, 4.5 parts of isopropanol, and 91.8 parts of deionized water;

[0095] The plant extract is composed of 7 parts by weight of Magnolia officinalis extract, 5 parts by weight of Scorpion grass extract and 3 parts by weight of Chonglou extract.

[0096] The stabilizer is composed of 1 weight part of sucrose, 4 weight parts of calcium dihydrogen phosphate, and 5 weight parts of sodium alginate.

[0097] The preparation method of described Magnolia officinalis extract is:

[0098] S01, washing Magnolia officinalis medicinal material, drying, pulverizing to 90 mesh, obtaining Magnolia officinalis powder;

[0099] S02. Add Magnolia officinalis powder into deionized water, extract at 75°C for 35 minutes to obtain Magnolia officinalis extract, and the ratio of Magnolia officinalis powder to deionized water is 1g:9ml;

[0100] S03. Add the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com