Thermocatalytic water decomposition reactor and thermocatalytic water decomposition hydrogen production system and method

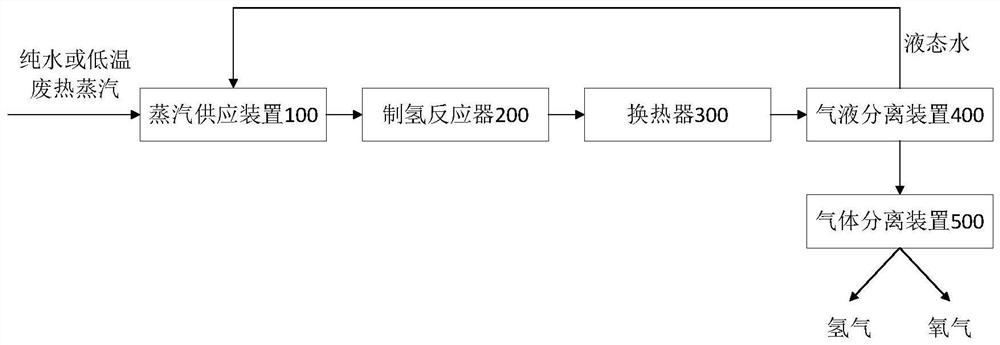

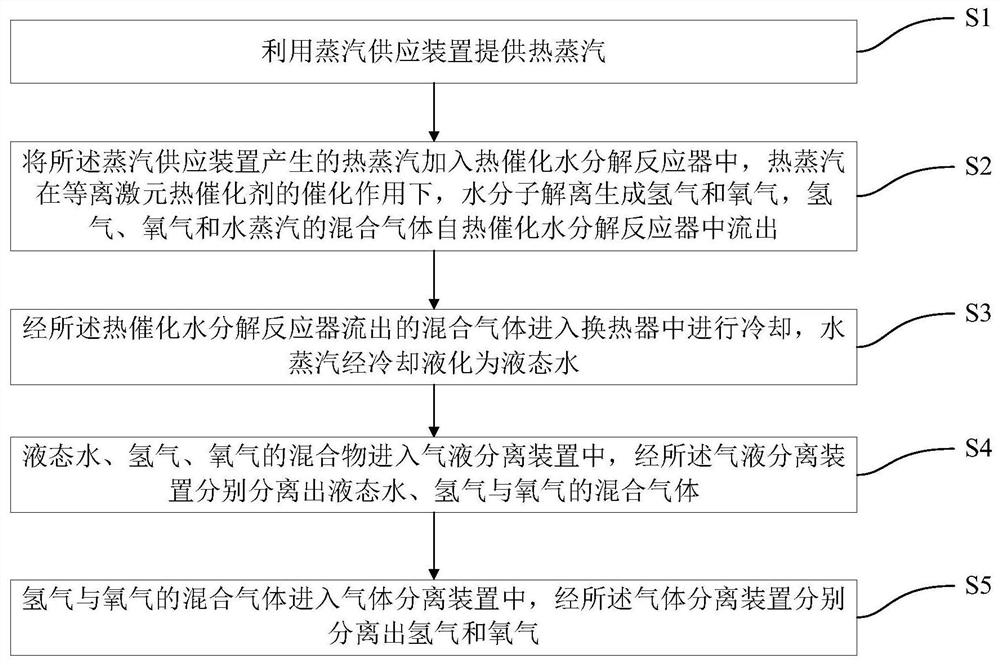

A decomposition reactor and thermal catalysis technology, applied in the field of hydrogen production, can solve problems such as being unsuitable for large-scale production applications, large area of equipment and equipment, and emission of air pollutants, so as to alleviate the energy crisis and reduce energy consumption for hydrogen production. , the effect of energy saving and emission reduction energy crisis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0030] It should be noted that in the present invention, the plasmon effect refers to a phenomenon in which high-energy thermal electrons are excited by thermal radiation light waves and the local energy field is enhanced. It has ultra-high energy utilization efficiency and can activate water A chemical bond in a molecule that promotes the breaking of hydrogen-oxygen bonds.

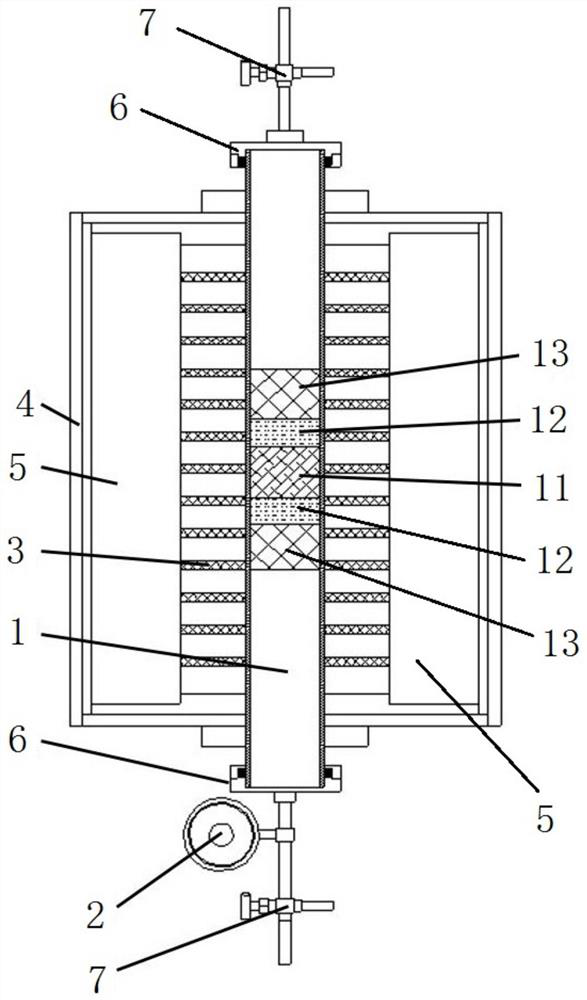

[0031] Such as figure 1 As shown, a thermocatalytic water splitting reactor according to an embodiment of the present invention includes a reaction tube 1, a temperature regulating device and a pressure monitoring device, wherein the reaction tube 1 is used as a reaction vessel for water splitting, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com