Rotary 12-nozzle jet-flow linear spray head

A rotary, spray head technology, applied in spray devices, spray devices with movable outlets, chemical instruments and methods, etc., can solve problems such as cracking, damage, easy oxidation, etc., to improve convenience, ensure service life, and easily fix The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

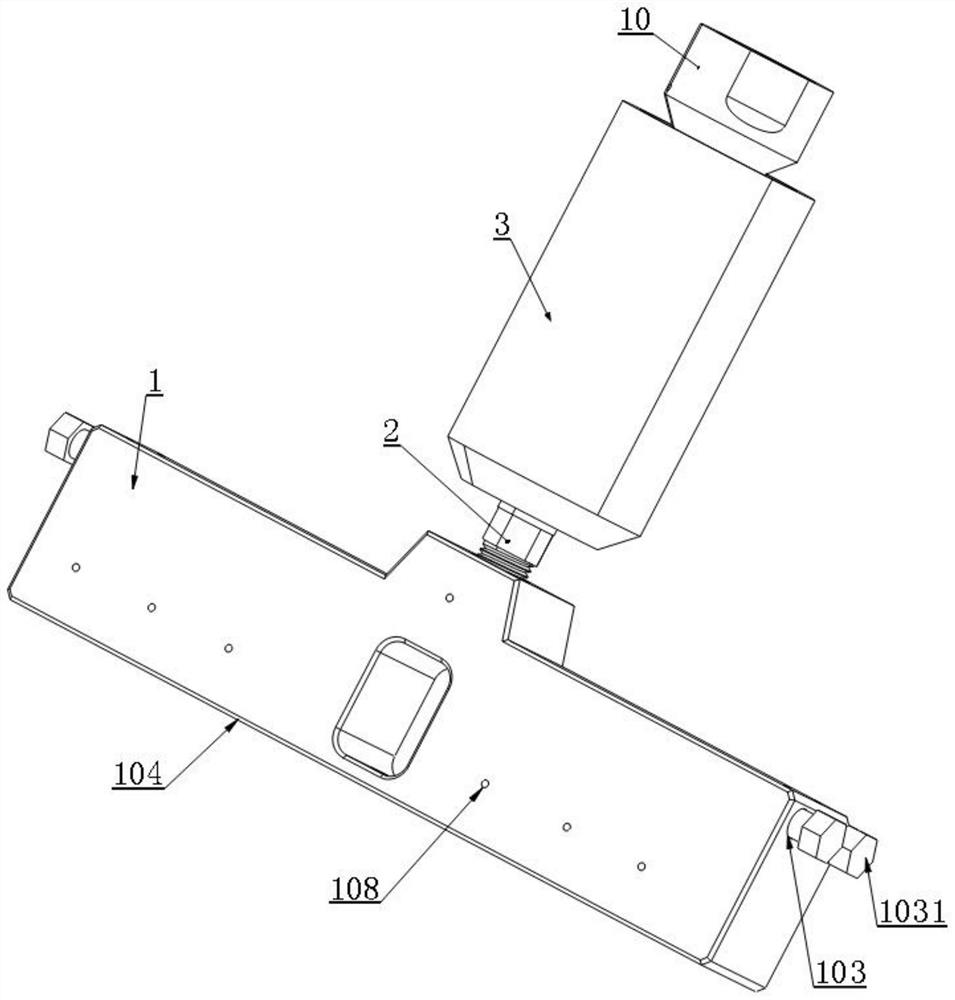

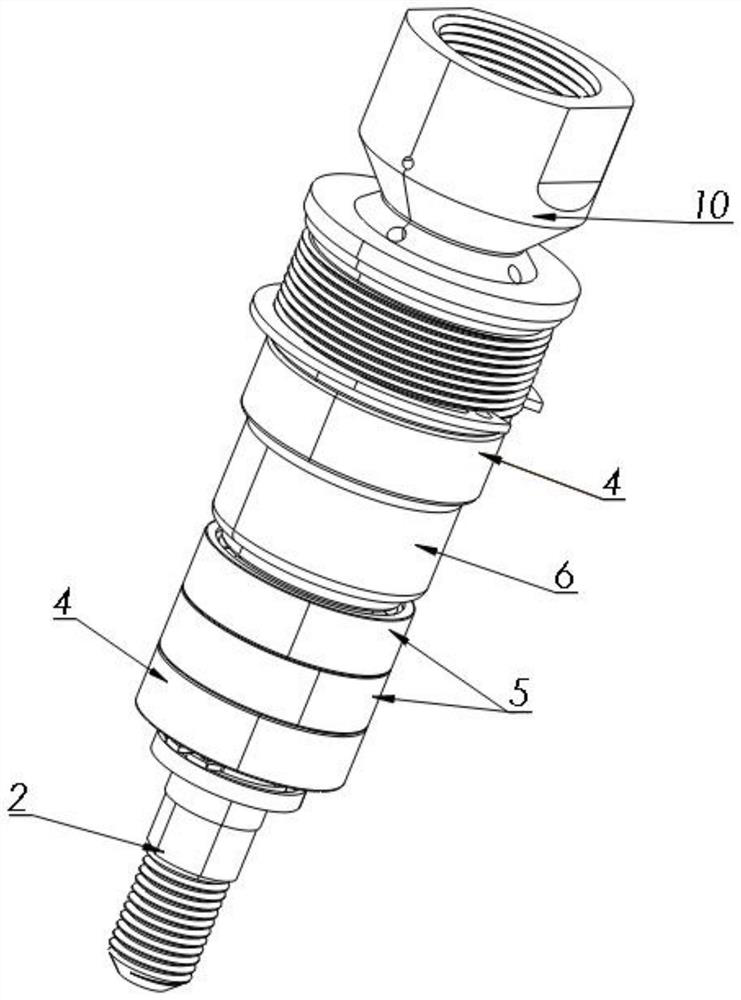

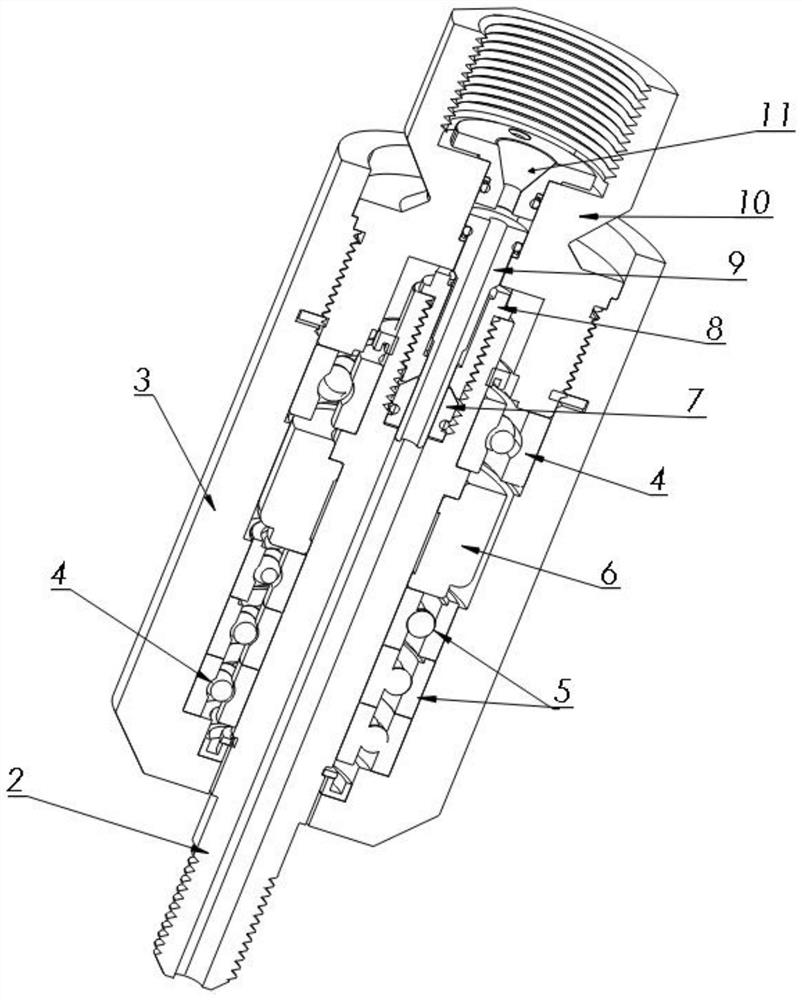

[0022] Such as Figure 1 to Figure 6 As shown, a rotary 12-nozzle jet in-line nozzle according to the present invention adopts a technical solution that includes a nozzle 1, a rotating shaft 2, a housing 3, a deep groove ball bearing 4, an angular contact ball bearing 5, and a magnetic assembly 6. High-pressure sealing head 7, hollow sealing locking bolt 8, sealing rod 9, water inlet joint 10, excessive sealing member 11.

[0023] The sprinkler head 1 has a T-shaped structure. A threaded hole 101 is set in the middle of the upper side wall of the sprinkler head 1. The bottom of the screwed hole 101 is set with a main water inlet sink hole 102. The left and right ends of the sprinkler head 1 are two A pressure relief counterbore 103 is provided symmetrically on the side, and the internal thread of the pressure relief counterbore 103 is connected to a plug cap 1031. The bottom of the nozzle 1 is provided with a nozzle installation hole 104. The bottoms of the holes 103 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com