Mechanical structure of automatic clamping device for mechanical polishing

A clamping device and mechanical polishing technology, which is applied to surface polished machine tools, grinding drive devices, and parts of grinding machine tools, etc., can solve problems such as workpiece deformation, affecting work efficiency, and uneven force on the workpiece, achieving guaranteed Position accuracy, reduce labor intensity, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

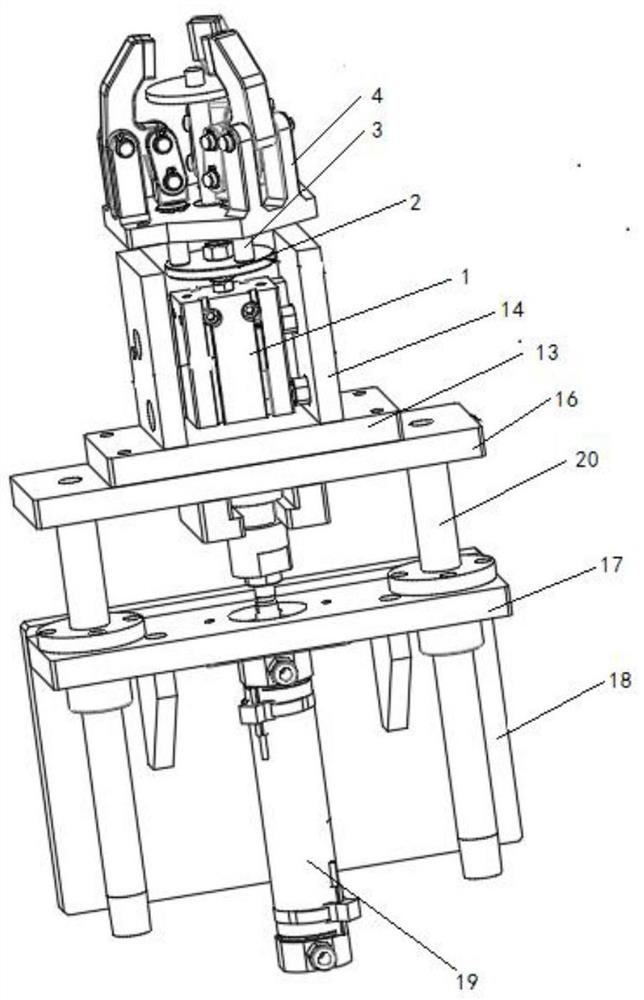

[0034] like figure 1As shown, a mechanical structure of an automatic clamping device for mechanical polishing, including a base, a motor 1, a motor frame, a turntable 2 and a pressing device, the motor 1 is fixed on the side plate 14 and the connecting plate 15 of the motor frame, and the motor The output shaft of 1 is perpendicular to the base, the motor frame is fixed on the base, the turntable 2 is installed on the output shaft of motor 1, and the pressing device is installed on the turntable 2;

[0035] like Figure 5 As shown, the base includes a first support plate 16, a second support plate 17, a riser 18, a second hydraulic cylinder 19 and a slide bar 20, the second support plate 17 is located below the first support plate 16, and the riser 18 is connected to One side of the second support plate 17, the vertical plate 18 is provided with mounting holes for fixing the base; the slide bar 20 is two, and one end of the slide bar 20 is connected on the first support plate...

Embodiment 2

[0043] Based on a method for using a mechanical structure of an automatic clamping device for mechanical polishing, the method includes the following steps:

[0044] Step 1. First place the workpiece to be polished on the pallet 11 of the bracket, and align the hollow part of the workpiece to be polished with the limit position

[0045] Column 12;

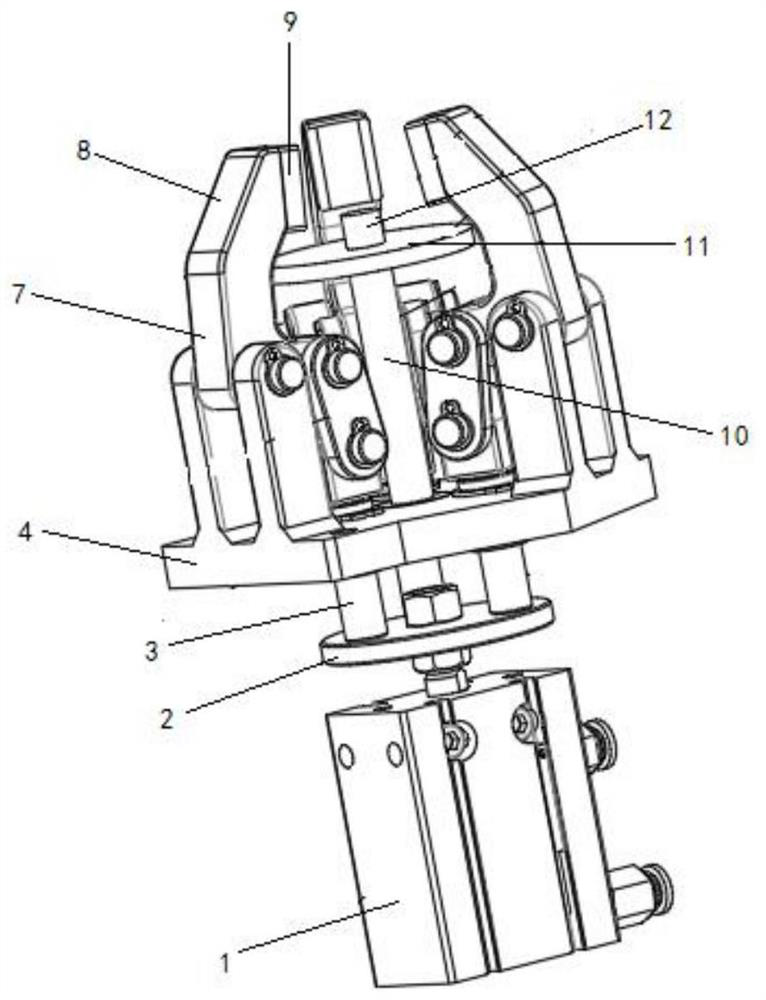

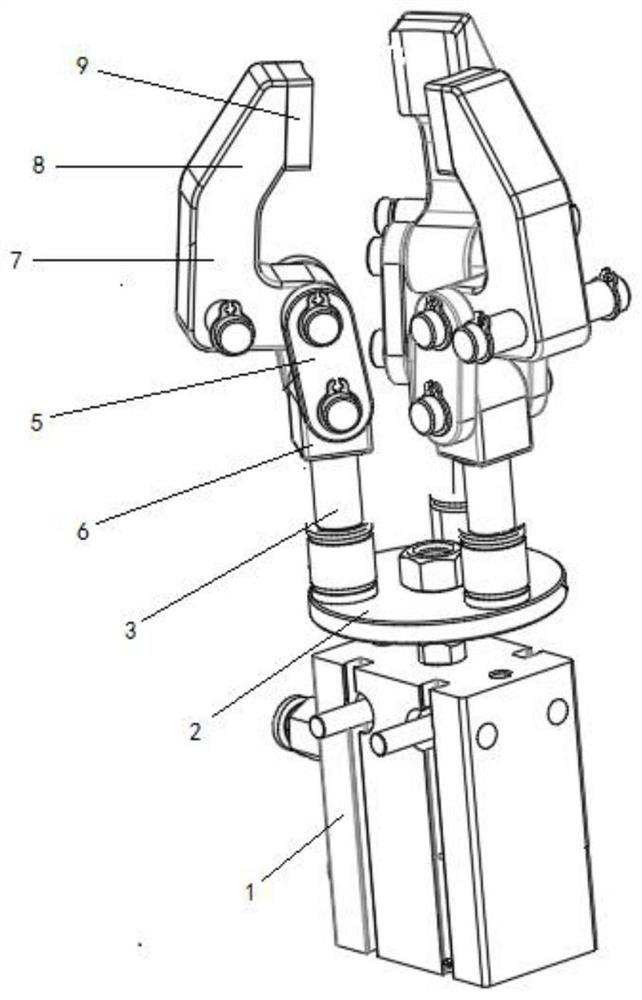

[0046] Step 2, then the infrared sensor on the pallet 11 senses the presence of the workpiece, and transmits the monitored data to the controller of the first hydraulic cylinder 3, and the controller of the first hydraulic cylinder 3 issues an instruction to start the first hydraulic cylinder 3 , so that the first piston rod moves down, and drives the connecting block 6, the connecting piece 5 and the clamping arm, so that the clamping block 6 on the clamping arm is close to each other, and the workpiece is clamped, and the pressure sensor collects the pressing force on the clamping arm in real time block 6 of the pressure data, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com