Adjustable composite stabilizer bar and assembling method thereof

A stabilizer bar, adjustable technology, applied in transportation and packaging, manufacturing tools, metal processing, etc., can solve the problems of product cost reduction, complicated assembly process, complex structure, etc., to reduce production and use costs, and realize mass processing production , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

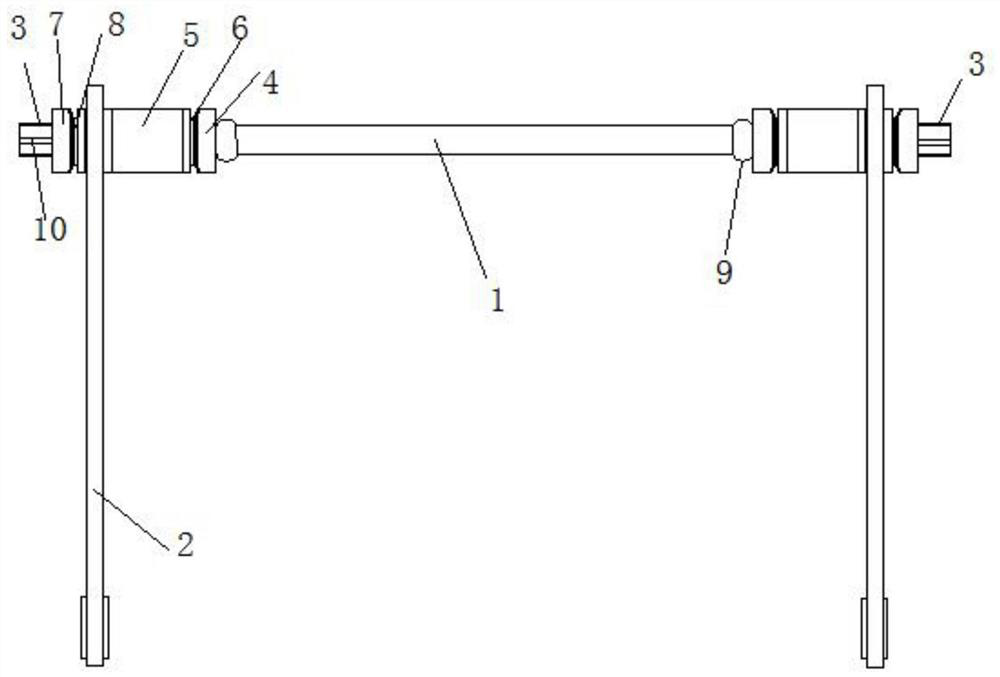

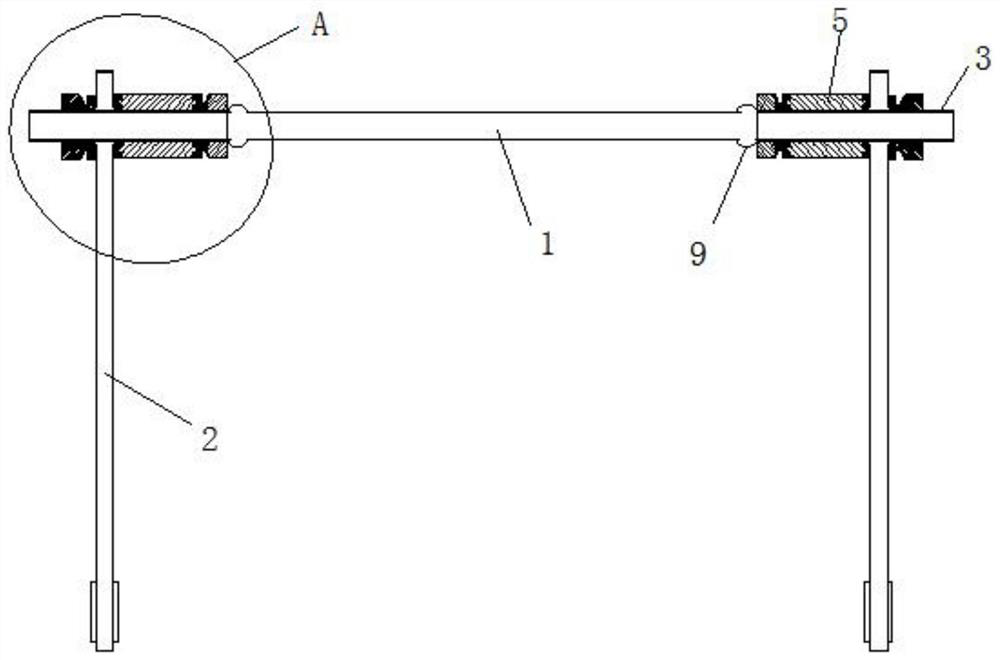

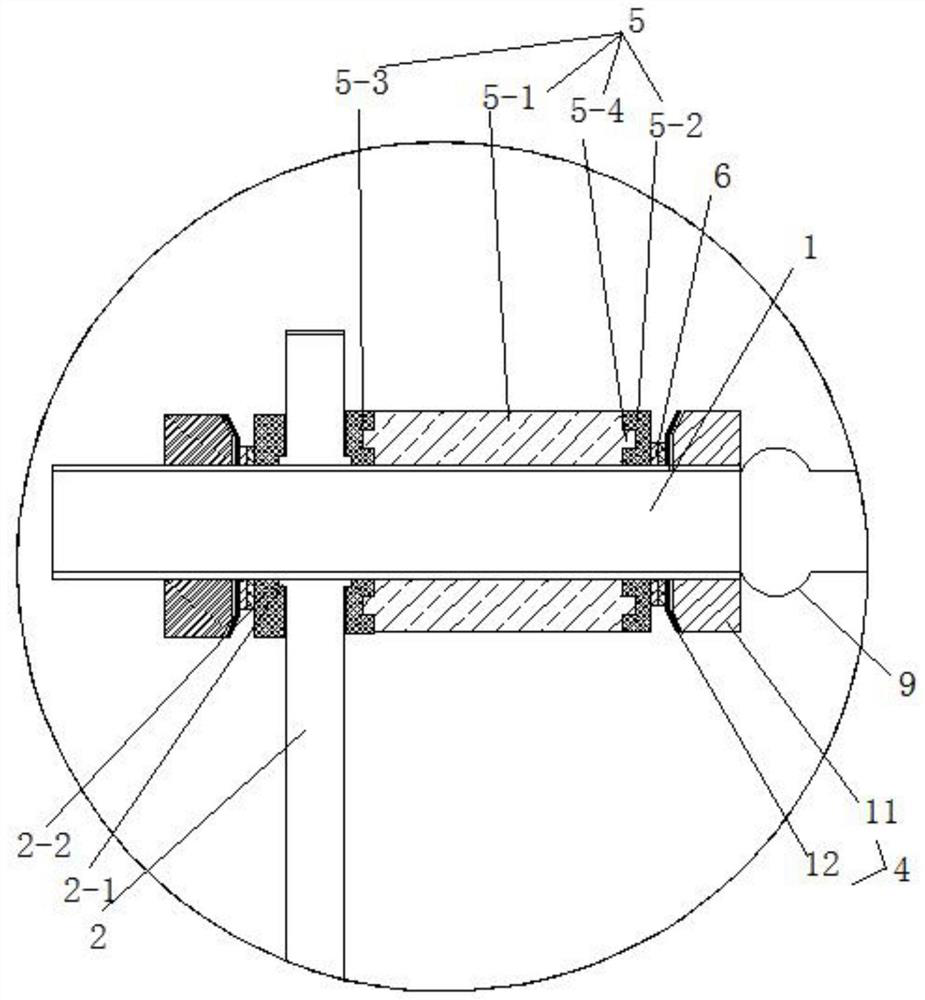

[0033] See attached picture.

[0034]An adjustable composite stabilizer bar, comprising a hollow torsion bar body 1, leaf springs 2 with adjustable center distances are respectively installed at both ends of the torsion bar body 1, and two sections of threads are respectively provided at both ends of the torsion bar body 1 Section 3, the leaf spring 2 is set on the threaded section 3, and the inner side of the leaf spring 2 is limited and fixed by the inner end fixing component. The inner end fixing component includes a fixing component 4 and an adjusting component 5. The fixing component 4 and adjusting An anti-loosening reinforcing component 6 is also installed between the components 5. The fixing component 4 and the adjusting component 5 are both screwed and fixed on the threaded section 3 of the torsion bar body 1, and the outer side of the leaf spring 2 is locked by the outer end. Components are locked and fixed, and the locking component includes a fixed component 2 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com