Aluminum foil sealing machine

A technology of sealing machine and aluminum foil, which is applied in the direction of closures, packaging sealing/fastening, safety/control of bottle capping machines, etc. Avoid the effect of weak seal paste and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

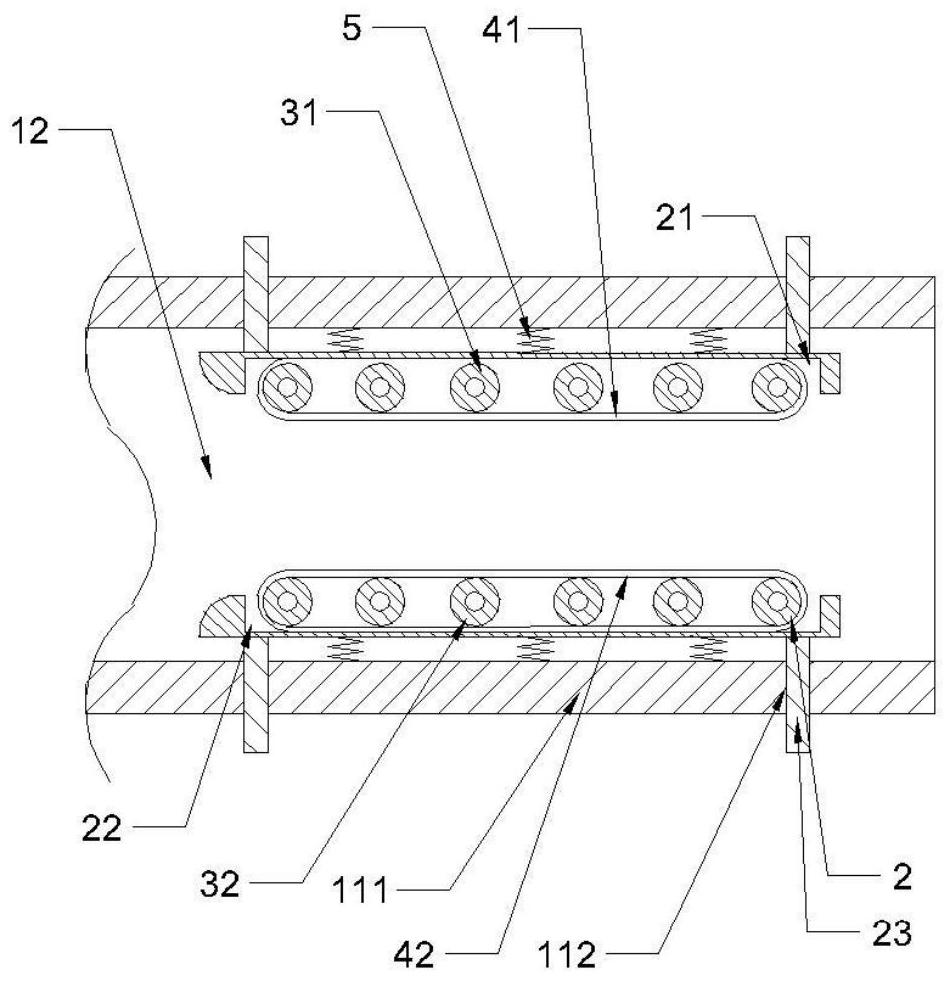

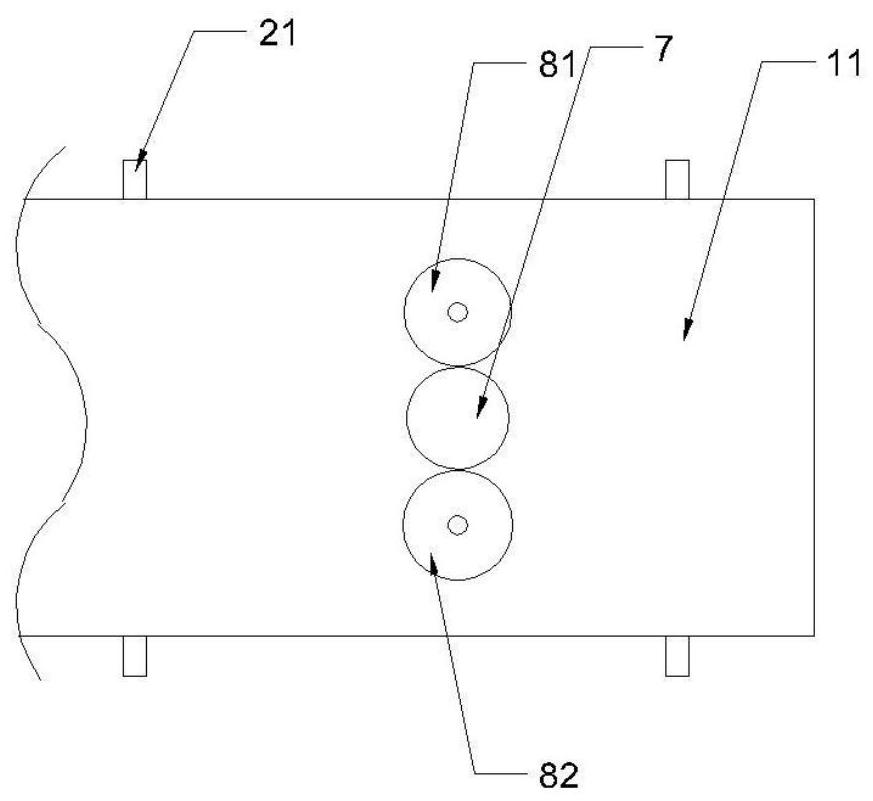

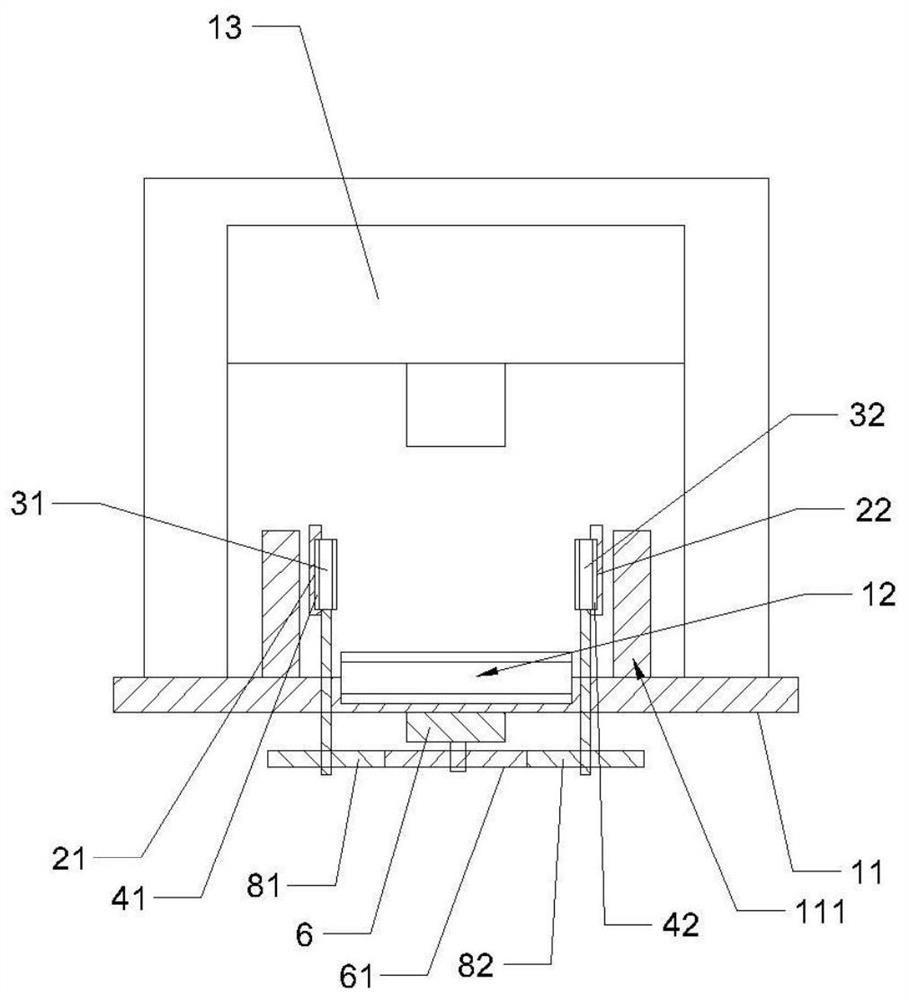

[0022] See attached Figure 1-3 , the present embodiment disclosed by the present invention is further provided with: an aluminum foil sealing machine, comprising a sealing machine frame 11, a conveyor belt 12 arranged on the frame, and an electromagnetic induction sealing device 13;

[0023] The sealing machine frame 11 is provided with a pair of baffle plates 111 above the transmission belt, and a pair of splints 2 are arranged between the pair of baffle plates 111. A sliding mechanism is connected between each splint 2 and the adjacent baffle plate 111, and a pair of splints 2 The relative slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com