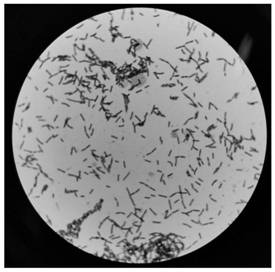

Bacillus tropicalis resistant to heavy metal degradation of waste engine oil

A technology of bacillus and waste engine oil, applied in the field of microorganisms, can solve the problems of heavy metal and petroleum hydrocarbon compound pollution, and achieve the effects of avoiding disadvantages and inapplicability, no secondary pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

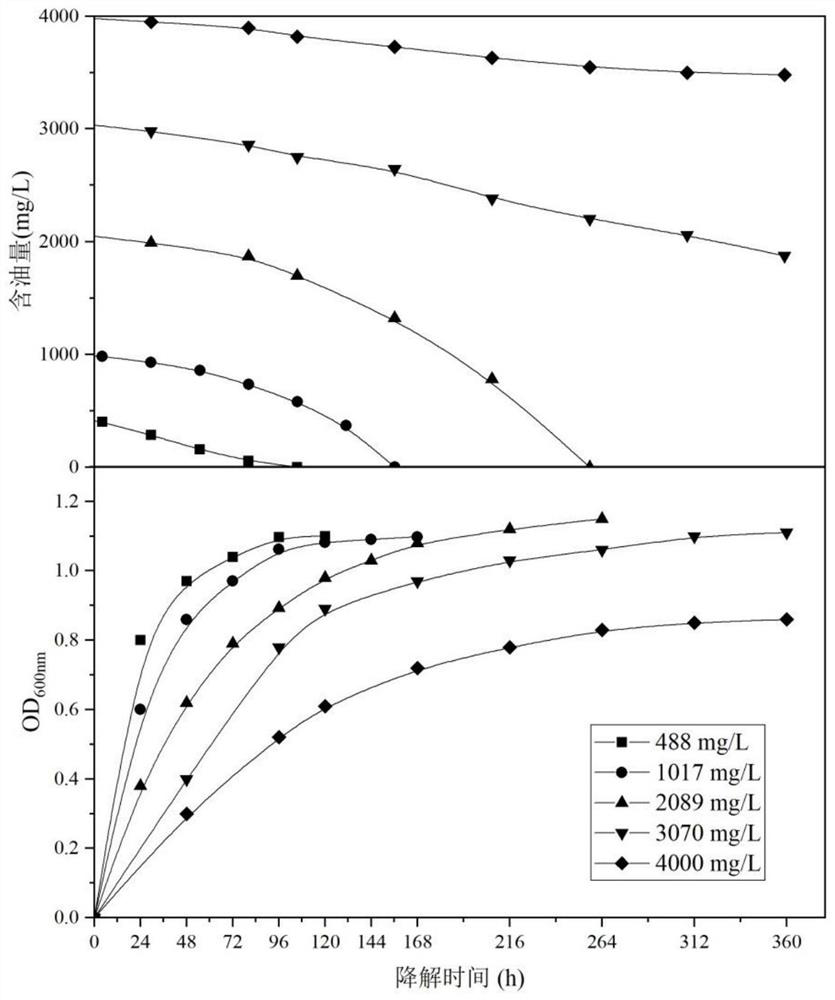

[0056] Study on the maximum degradation ability of bacteria strains to waste engine oil.

[0057] In order to study the maximum degradation ability of Bacillus tropicalis for waste engine oil, the cell fermentation broth (OD 600nm =1.3±0.02) Inoculate 10% of the inoculum amount into 100mL inorganic salt medium containing different concentrations of waste engine oil (initial concentrations of waste engine oil are 488, 1017, 2089, 3070, 4000mg / L respectively), and the initial pH value is adjusted The temperature is 7.0, the temperature is 35°C, shake culture at 160r / min to carry out the shaking flask experiment of Bacillus tropicalis degrading waste engine oil, and monitor two indicators respectively: 1) the concentration of waste engine oil in the sample liquid and calculate the degradation rate of waste engine oil, the waste engine oil The level of oil degradation rate represents the strength of the degradation ability of the bacteria at this concentration; 2) Determination of...

Embodiment 2

[0059] Research on the ability of strains to tolerate Cr(Ⅵ), Cd(Ⅱ), Cu(Ⅱ) and Pb(Ⅱ).

[0060] To study the tolerance of Bacillus tropicalis to Cr(VI), Cd(II), Cu(II), and Pb(II), the cell fermentation broth (OD 600nm =1.3±0.02) inoculate 30mL LB medium (Cr(Ⅵ), Cu(Ⅱ) The actual concentration of Pb(Ⅱ) is 50mg / L~550mg / L gradient increase; the actual concentration of Cd(Ⅱ) is 2mg / L~120mg / L gradient increase), the initial pH value is adjusted to 7.0, and the temperature At 35°C, shake culture at 160r / min for 24h to carry out the shake flask experiment of Bacillus tropicalis resistant to heavy metals Cr(VI), Cd(II), Cu(II), and Pb(II), and monitor the OD in the sample solution 600nm value. Figure 3-4 It reflects the resistance of Bacillus tropicalis to different initial concentrations of Cr(Ⅵ), Cd(Ⅱ), Cu(Ⅱ), and Pb(Ⅱ). It can be seen that the maximum tolerance concentrations of Bacillus tropicalis to Cr(Ⅵ), Cd(Ⅱ), Cu(Ⅱ), and Pb(Ⅱ) are 535mg / L, 120mg / L, 230mg / L, and 200mg / L, resp...

Embodiment 3

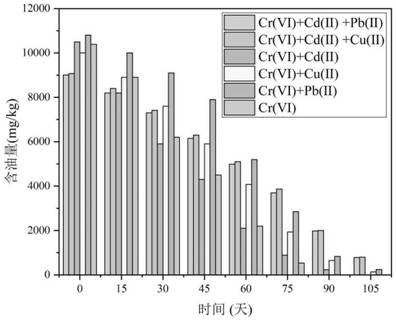

[0062] Study on the degradation ability of strains of waste engine oil under single metal stress.

[0063] In order to study the degradation ability of Bacillus tropicalis under single metal stress, the cell fermentation liquid (OD 600nm =1.3±0.02) Inoculate 60mL inorganic salt medium containing different concentrations of heavy metals (Pb(II), Cu(II), Cr(VI), Cd(II) at 10mg / L, 20mg / L, 30mg / L, 40mg / L, 50mg / L, 60mg / L, 70mg / L, 80mg / L, 90mg / L), the initial waste engine oil concentration is 500mg / L, and the initial pH value is adjusted to 7.0, The temperature is 35°C, shake culture at 160r / min for 120h to carry out the shake flask experiment of Bacillus tropicalis degrading waste engine oil, monitor the concentration of waste engine oil in the sample liquid, Figure 5 It reflects the degradation of waste engine oil by Bacillus tropicalis under the stress of different concentrations and different types of heavy metals. It can be seen that when the concentration of Pb(II), Cu(II)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com