Discharge port monitoring device with silt-resistant function

A monitoring device and function technology, applied in the field of water environmental protection engineering, can solve the problems of difficulty in maintenance and adjustment, inability to deploy, and difficult to adapt to sediment, etc., and achieve the effects of good anti-siltation ability, avoidance of siltation interference, and convenient installation and construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

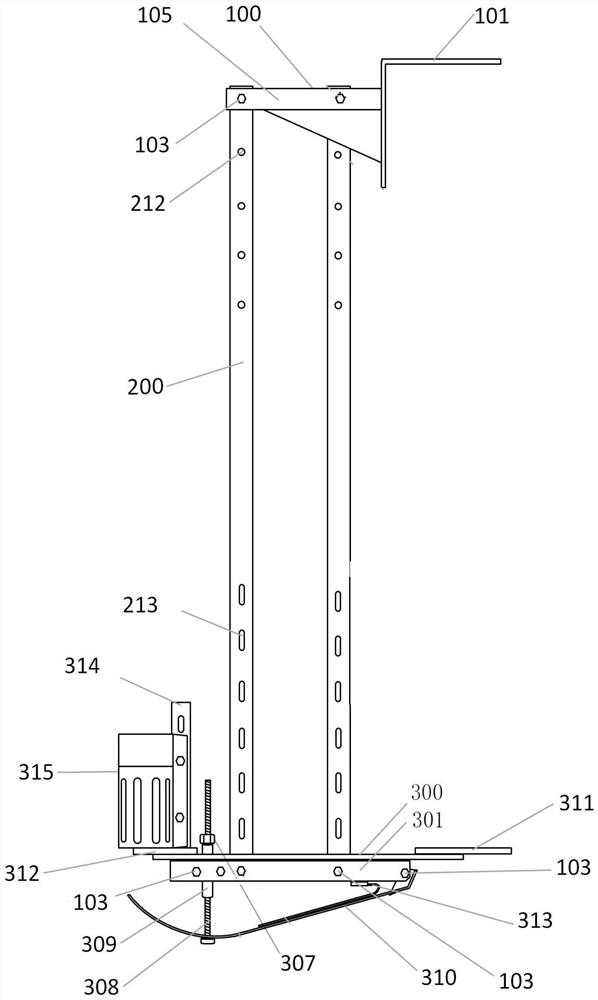

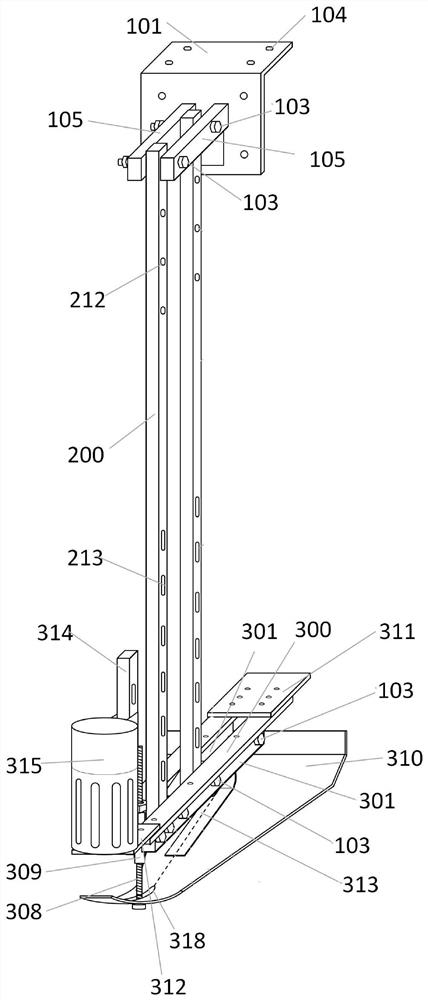

[0037] like figure 1 and 2 As shown, a discharge monitoring device with anti-silting function includes a parallelogram movable frame and an anti-silting mechanism. The movable frame includes a top bracket 100, an underwater workbench 300 and two movable cantilevers 200. The top The bracket 100 is horizontally and fixedly installed on the top of the monitoring section of the outlet, and the two ends of the top bracket 100 are respectively hinged to one of the movable cantilever 200, and the two ends of the underwater workbench 300 are respectively hinged to two of the movable cantilever 200 and the top bracket 100 is arranged parallel to the underwater workbench 300; the bottom of the underwater workbench 300 is equipped with the anti-silting mechanism, and the anti-silt mechanism includes an adjustable bottom plate 310, a tension spring piece 313 and a telescopic assembly, one end of the adjustable bottom plate 310 is hinged to the underwater workbench 300, the other end of t...

Embodiment 2

[0063] The present invention is on the basis of embodiment 1:

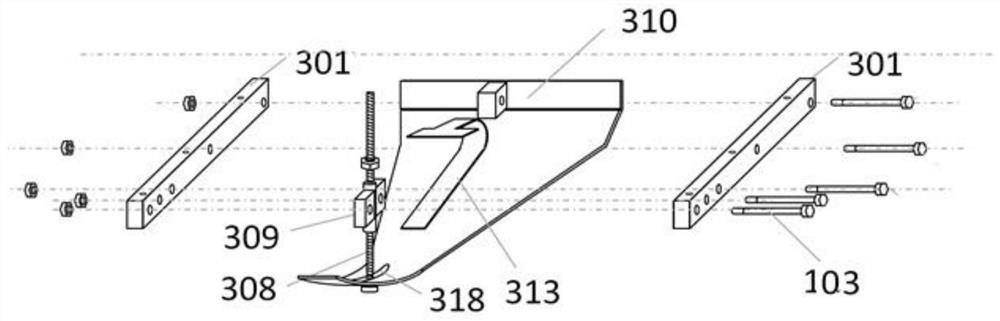

[0064] like image 3 As shown, the telescopic assembly includes an adjusting screw 308 and a sliding joint sleeve 309, the sliding joint sleeve 309 is movably installed on the underwater workbench 300, and the sliding joint sleeve 309 can rotate in the longitudinal direction of the underwater workbench 300 One end of the adjusting screw 308 is movably connected to the adjustable bottom plate 310, and the other end of the adjusting screw 308 passes through the sliding joint sleeve 309 and is located above the underwater workbench 300, and a limiter is set at the passing end. bit nut 307 .

[0065] The rear end backwater direction of the underwater workbench 300 is provided with a sliding joint cover 309, and the sliding joint cover 309 has no thread inside, and an adjusting screw rod 308 that can slide up and down is worn. The lower end of the adjusting screw 308 is movably connected to the adjustable bottom plat...

Embodiment 3

[0070] The present invention is on the basis of embodiment 2:

[0071] The adjustable bottom plate 310 is provided with a longitudinal sliding slot 318 , and the end of the adjusting screw 308 is engaged in the longitudinal sliding slot 318 and can move along the longitudinal sliding slot 318 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com