Novel water flow distributor for fan coil

A water flow distribution and fan coil technology, which is applied in the field of new water flow distributors for fan coil units, can solve the problems of large material consumption, reduce processing difficulty, secure welding connections, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

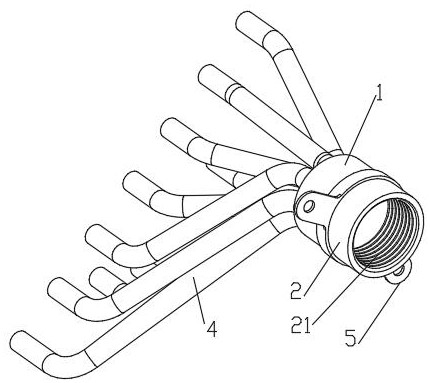

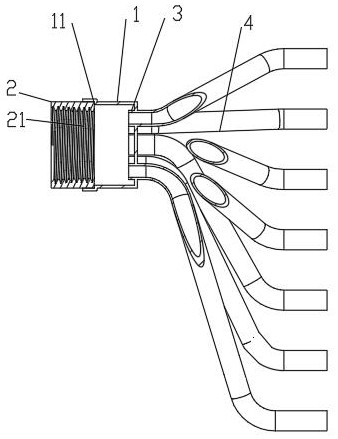

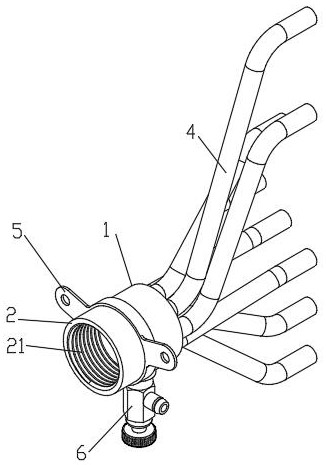

[0027] like Figures 1 to 10 It is a structural schematic diagram of the present invention, a new type of water flow distributor for fan coil units, which is characterized in that it includes a connected cavity structure 1 for distributing water flow or converging water flow and a connecting part 2 with openings at both ends. One end of the body structure 1 is open or provided with an end plate 12, and a number of shunt holes 3 are provided on the end wall or side wall of the other end. The opening of the cavity structure 1 or the end plate 12 is provided with a counterbore 11 for accommodating the connecting part 2 , one end of the connecting portion 2 is fixed in the counterbore 11 , and the branch pipe 4 is fixed at the branch hole 3 .

[0028] Specifically, this water flow distributor adopts a segmented design, one section is a cavity structure 1 with a larger inner diameter, which is used to better accommodate and distribute water flow, and the other section is a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com