Explosion-proof mechanism for drying oven

An oven, explosion-proof device technology, applied in dryers, drying, local stirring dryers and other directions, can solve problems such as easy to cause safety accidents, limited explosion-proof effect, increase oven pressure, etc., to ensure heating and prevent temperature difference. , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

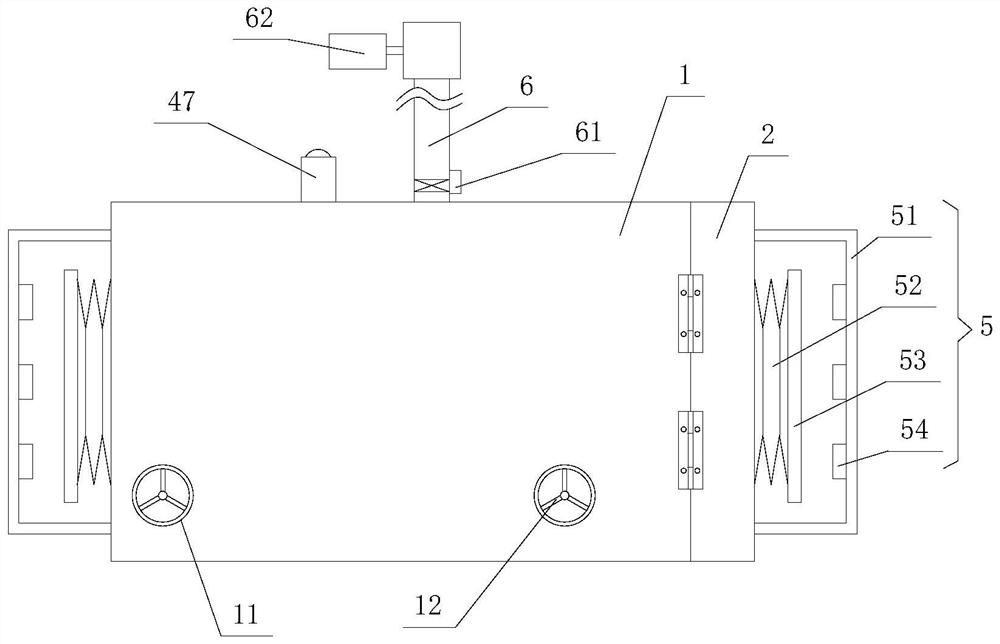

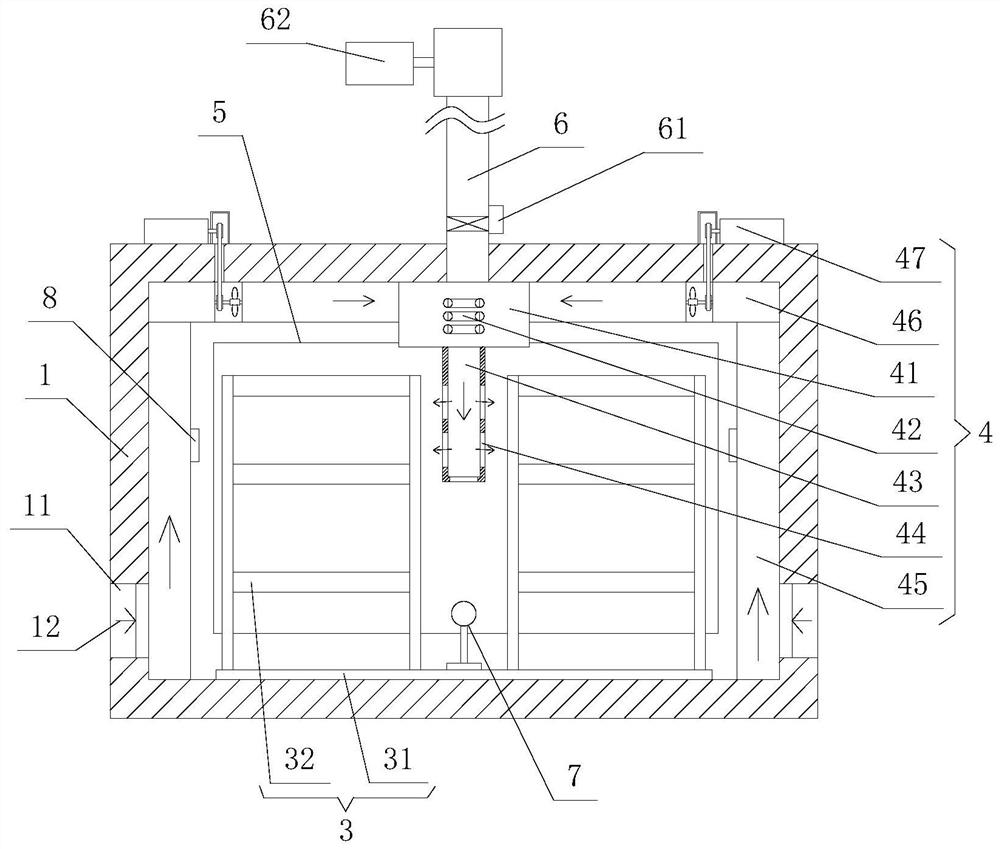

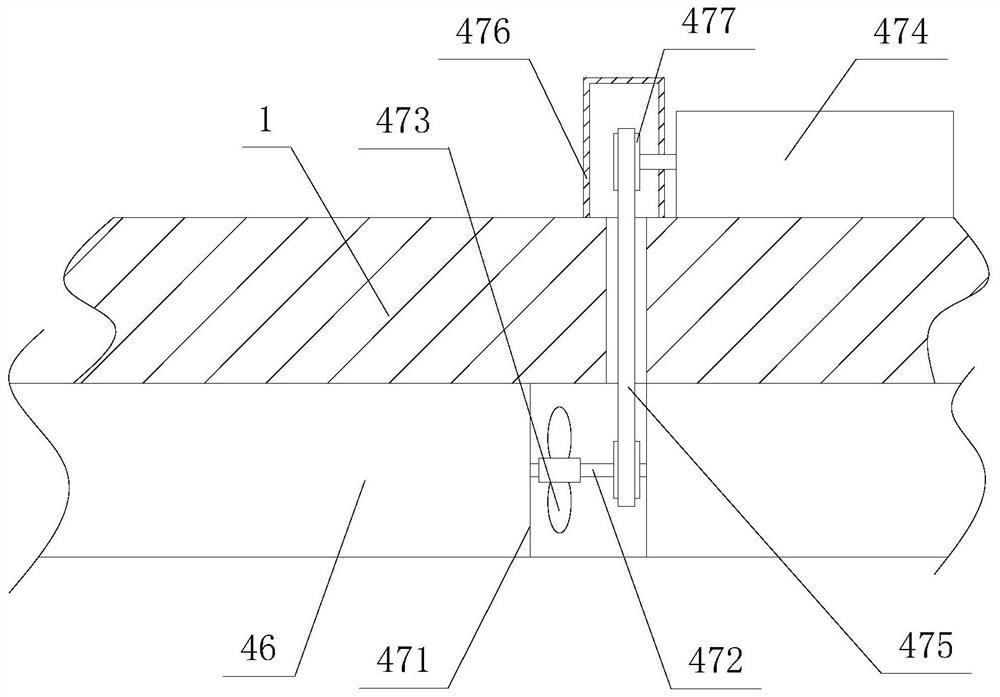

[0022] like Figure 1 to Figure 4 As shown, the oven explosion-proof mechanism provided in this embodiment includes a box body 1, a box door, a shelf 3, a heating device 4 and an explosion-proof device 5. The box body 1 is hinged with an openable box door, and inside the box body 1 A storage rack 3 is installed, and the storage rack 3 includes a base plate 31 and two groups of brackets 32 installed on the base plate 31 in turn. There is a gap for the flow of hot air between the two groups of brackets 32. By dividing the brackets 32 into The two groups can facilitate the flow of hot air between the brackets 32, thereby ensuring the uniformity of heating and preventing uneven heating. A heating device 4 is installed in the box body 1, and the heating device 4 includes heating pipes 41, Heater 42, air duct plate 45 and two-way blower 47, described heating pipe 41 is installed on the top inside casing 1, and heater 42 is installed in heating pipe 41, and the bottom of heating pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com