Polyvinyl alcohol sponge with ordered porous structure prepared based on 3D printing template

A polyvinyl alcohol sponge, 3D printing technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., to achieve the effects of improving hemostasis efficiency, shortening coagulation time, rapid guidance and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

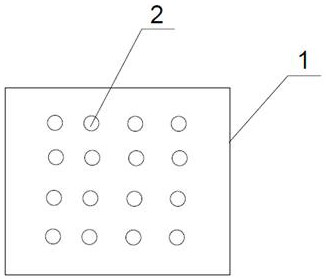

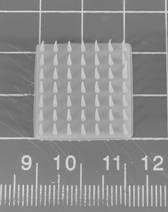

[0045] A polyvinyl alcohol sponge with an ordered porous structure prepared based on a 3D printing template, including a sponge body, the sponge body is provided with a number of hemostatic channel structures in regular and orderly arrays, and the hemostatic channel structure is cylindrical .

Embodiment 2

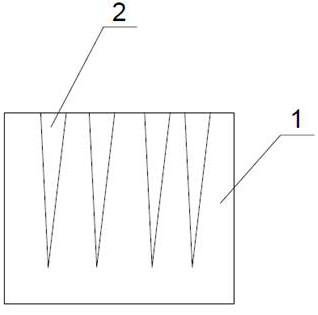

[0047]A polyvinyl alcohol sponge with an ordered porous structure prepared on the basis of a 3D printing template, including a sponge body, the sponge body is provided with a number of hemostatic channel structures in regular and orderly arrays, and the hemostatic channel structure is an upper large The lower small inverted cone structure, the large mouth of the inverted cone structure is the upper mouth located on the surface of the sponge body, and the small mouth is the lower mouth located inside the sponge body, the hemostatic channel structure of the inverted cone structure The taper is 1 / 2.

Embodiment 3

[0049] A polyvinyl alcohol sponge with an ordered porous structure prepared on the basis of a 3D printing template, including a sponge body, the sponge body is provided with a number of hemostatic channel structures in regular and orderly arrays, and the hemostatic channel structure is an upper large The lower small inverted cone structure, the large mouth of the inverted cone structure is the upper mouth located on the surface of the sponge body, and the small mouth is the lower mouth located inside the sponge body, the hemostatic channel structure of the inverted cone structure The taper is 2 / 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com