Preparation method for glucomannan acid hydrolyzed product

A technology of glucomannan and hydrolyzate, which is applied in the field of glucomannan acid hydrolyzate and its preparation, to achieve the effects of controllable molecular weight, easy operation and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

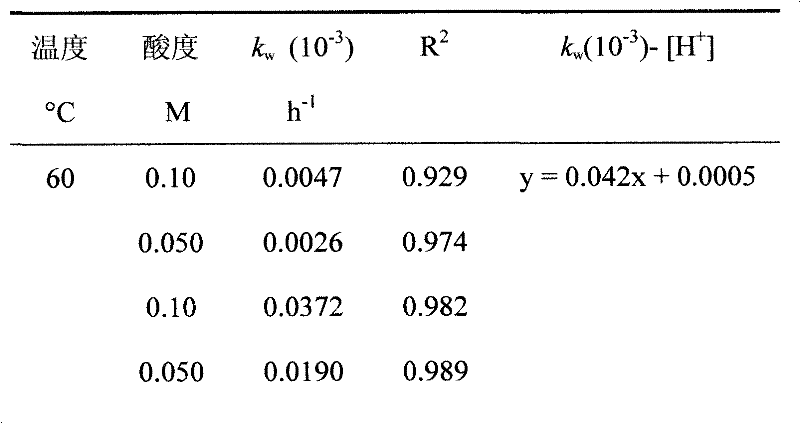

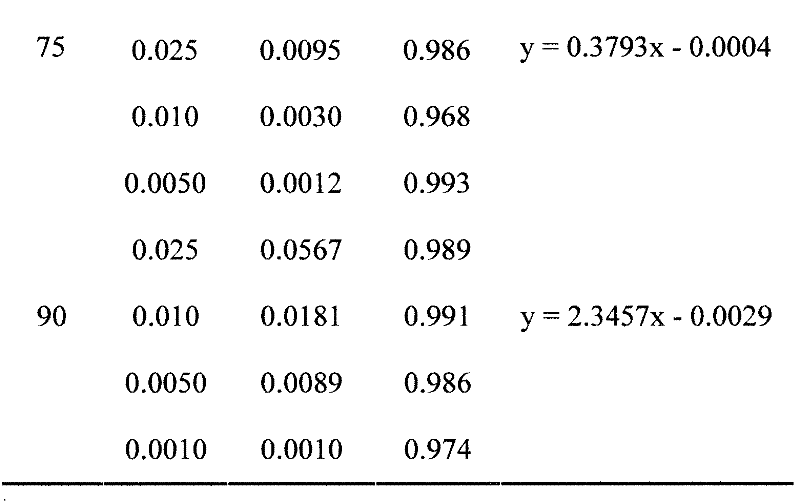

Method used

Image

Examples

Embodiment 1

[0051] Preparation of the acid hydrolyzate of Baiji polysaccharide described in this example:

[0052] Weigh 10.0 g of Baiji polysaccharide (BT01) into a 2000 mL beaker, add 900 mL of distilled water, and heat to dissolve on a 60°C water bath. Set the temperature of the water bath to 75°C. After equilibrium, add 5mL of 1M HCl solution according to 0.5% (v / v) of the final volume of the solution to make up water so that the acid concentration is 0.005M and the final polysaccharide concentration in the solution is 1%. Timed, reacted for 3h 23min, took it out, cooled it in cold water immediately, quickly added 1M NaOH solution dropwise to neutralize to pH 6-7, and obtained the hydrolyzate. Add absolute ethanol (or 95% ethanol) to the hydrolyzed solution until the alcohol concentration is 60%, precipitate the hydrolyzed product, and dry to prepare Baiji polysaccharide BT02.

Embodiment 2

[0054] Preparation of the acid hydrolyzate of Baiji polysaccharide described in this example:

[0055] Weigh 10.0 g of Baiji polysaccharide (BT01) into a 1000 mL beaker, add 400 mL of distilled water, and heat to dissolve on a 60°C water bath. Set the temperature of the water bath to 85°C. After equilibrium, add 8 mL of 1M HCl solution according to 0.8% (v / v) of the final volume of the solution to make up water so that the acid concentration is 0.008M and the final polysaccharide concentration in the solution is 2%. Timed, reacted for 2.5 hours, and the subsequent treatment was the same as in Example 1 to prepare Baiji polysaccharide BT05.

Embodiment 3

[0057] Preparation of the acid hydrolyzate of Baiji polysaccharide described in this example:

[0058] Weigh 10.0 g of Baiji polysaccharide (BT01) into a 1000 mL beaker, add 400 mL of distilled water, and heat to dissolve on a 60°C water bath. Set the temperature of the water bath to 95°C. After equilibrium, add 8 mL of 1M HCl solution according to 0.8% (v / v) of the final volume of the solution to make up water so that the acid concentration is 0.008M and the final polysaccharide concentration in the solution is 2%. Timed, reacted for 3.5 hours, and the subsequent treatment was the same as in Example 1 to prepare Baiji polysaccharide BT07.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com