Food additive blending device and blending steps

A technology for food additives and additives, applied in mixers with rotary stirring devices, mixer accessories, dissolution and other directions, can solve the problems of poor quality of additives, affecting efficiency, mixing methods and trouble using machines, etc. Efficiency and the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

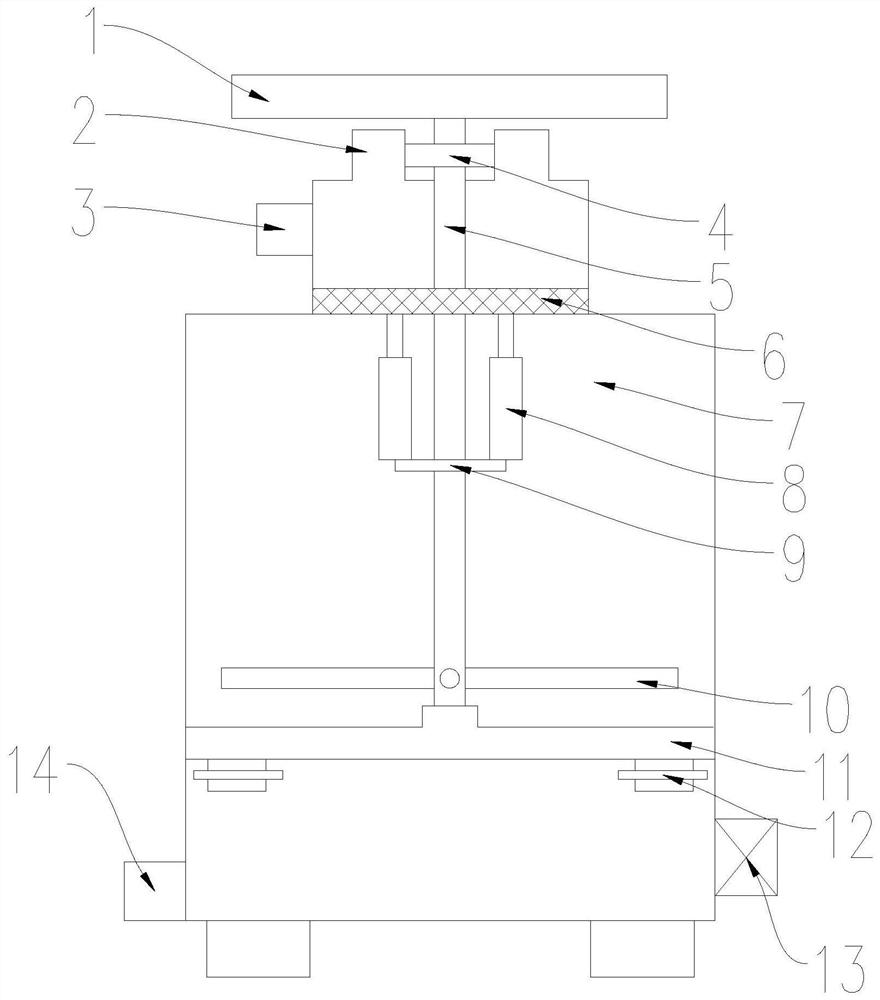

[0022] Example 1, such as figure 1 Shown:

[0023] A food additive blending device and blending steps, including the following preparation steps:

[0024] (1) Sodium benzoate, caramel pigment, sodium cyclamate, essence, tartaric acid, and biochemical enzymes are dropped into clean water respectively, and preliminary stirring is carried out earlier to generate additive solution 1;

[0025] (J) Put mineral salt components into the additive solution 1, then add it to the blending device, carry out fine mixing and blending, and then discharge to generate the additive solution 2;

[0026] (K) Add a little salt granules and grease to the additive solution two, and use a stirring bar to mix and prepare for the third time to generate the additive solution three;

[0027] (L) Use a heating machine to heat the additive solution 3 for 20 minutes, take it out after heating, and let it stand at room temperature of 25 degrees Celsius.

[0028] Among them, the blending device includes a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com