Method for reducing overflow of coiled inner ring of cold tandem mill

A technology of cold tandem rolling mill and inner ring, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of running speed mismatch, strip loss and deviation, and belt head lateral deviation, etc., to achieve Steadily improve the quality, change the shape of the roll gap, and improve the effect of the plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

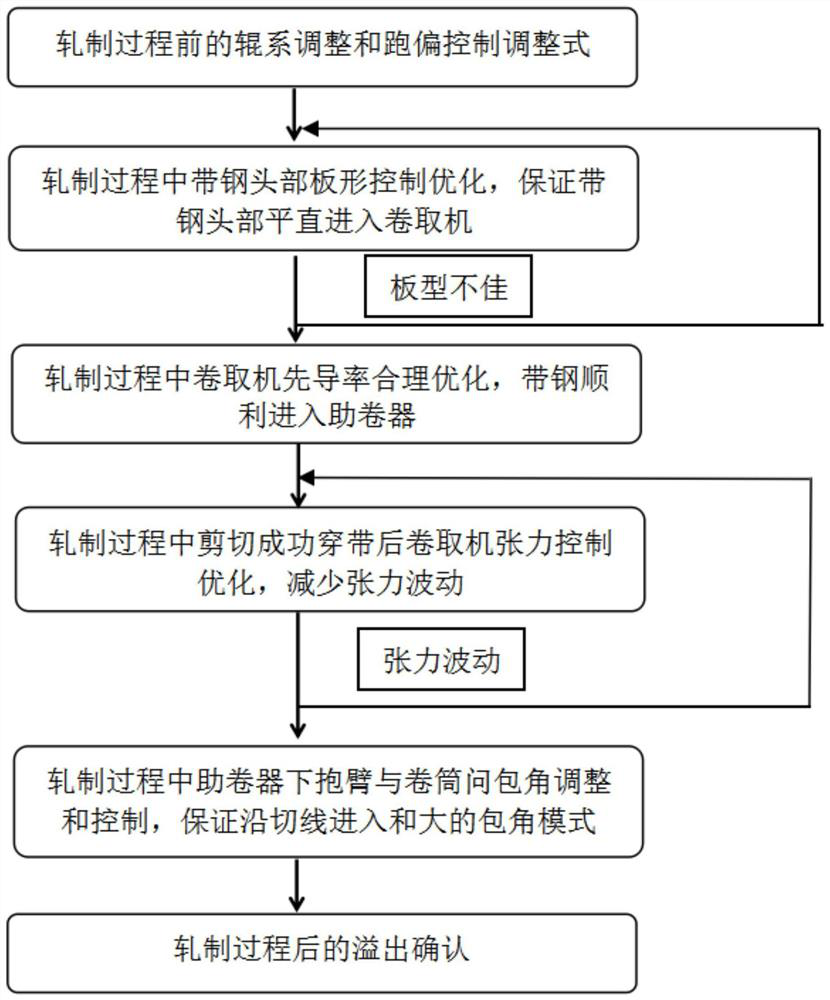

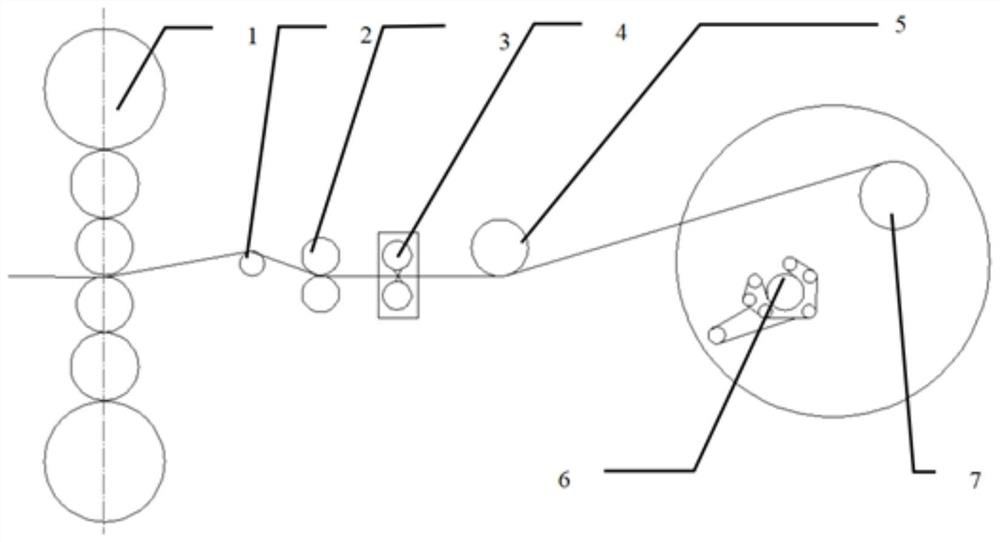

[0066] Example 1: see figure 1 , a method for reducing the overflow of the coiled inner ring of a cold tandem rolling mill, said method comprising the following steps:

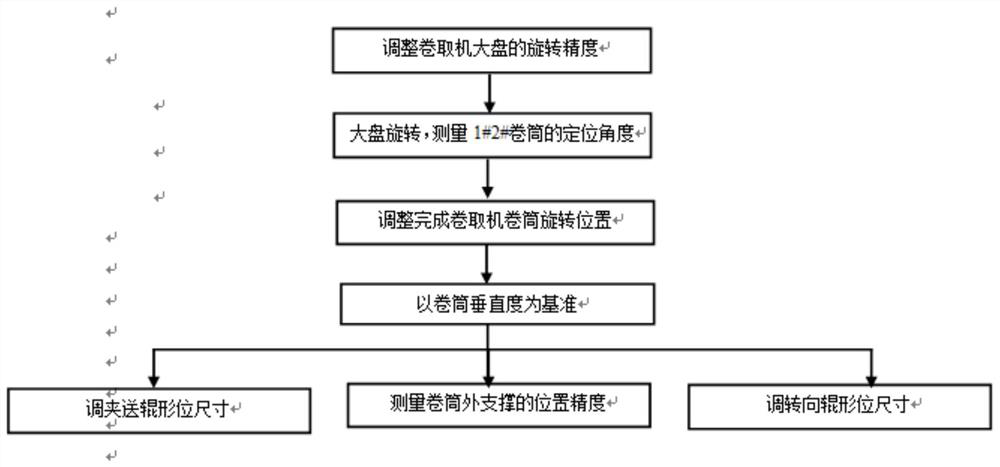

[0067] Step 1: Roll system adjustment and deviation control adjustment before the rolling process;

[0068] Step 2: Optimizing the shape control of the strip head during the rolling process to ensure that the strip head enters the coiler straight;

[0069] Step 3: During the rolling process, the pilot ratio of the coiler is reasonably optimized, and the strip enters the coiler smoothly;

[0070] Step 4: Optimizing the tension control of the coiler after successful shearing and threading during the rolling process to reduce tension fluctuations;

[0071] Step 5: During the rolling process, adjust and control the wrapping angle between the lower arm of the coiler and the reel to ensure entry along the tangent line and a large wrapping angle;

[0072] Step 6: Spill confirmation after rolling process.

[0073]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

| Verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com