Abrasive belt sand blasting device

A sandblasting device and abrasive belt technology, applied in metal processing equipment, manufacturing tools, abrasives, etc., can solve problems such as the reduction of the tensile strength of abrasive belts, improve positioning accuracy, increase tensile strength, and increase roughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-6 The application is described in further detail.

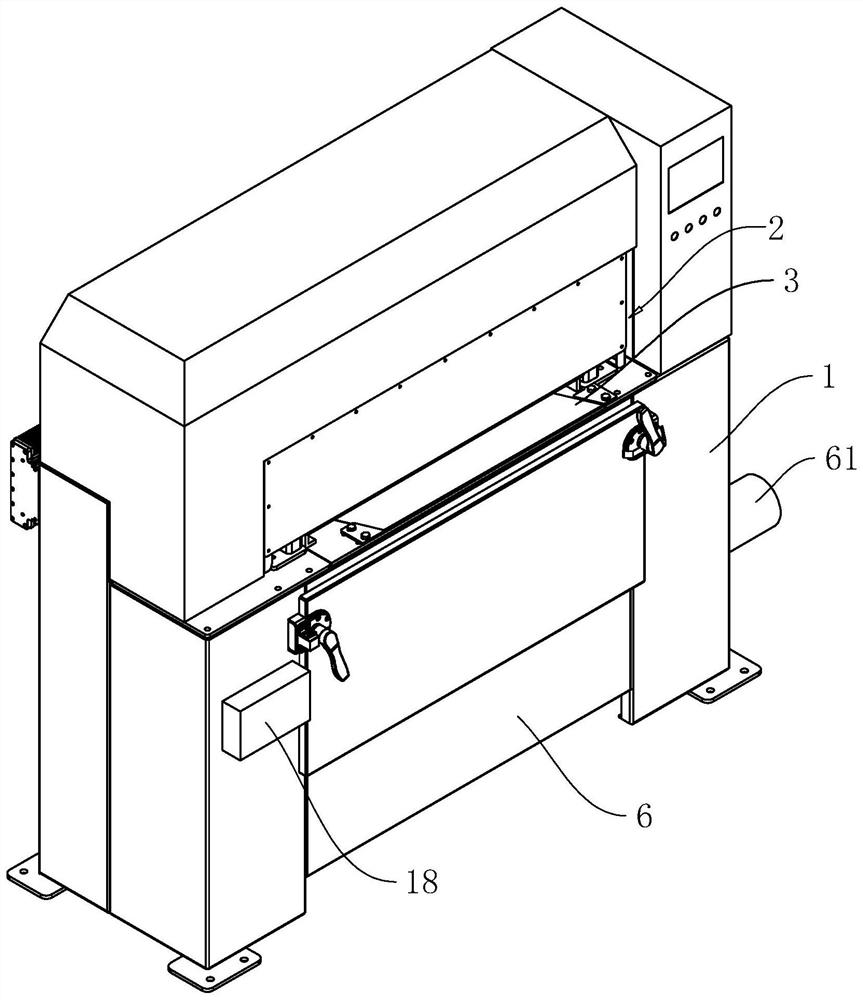

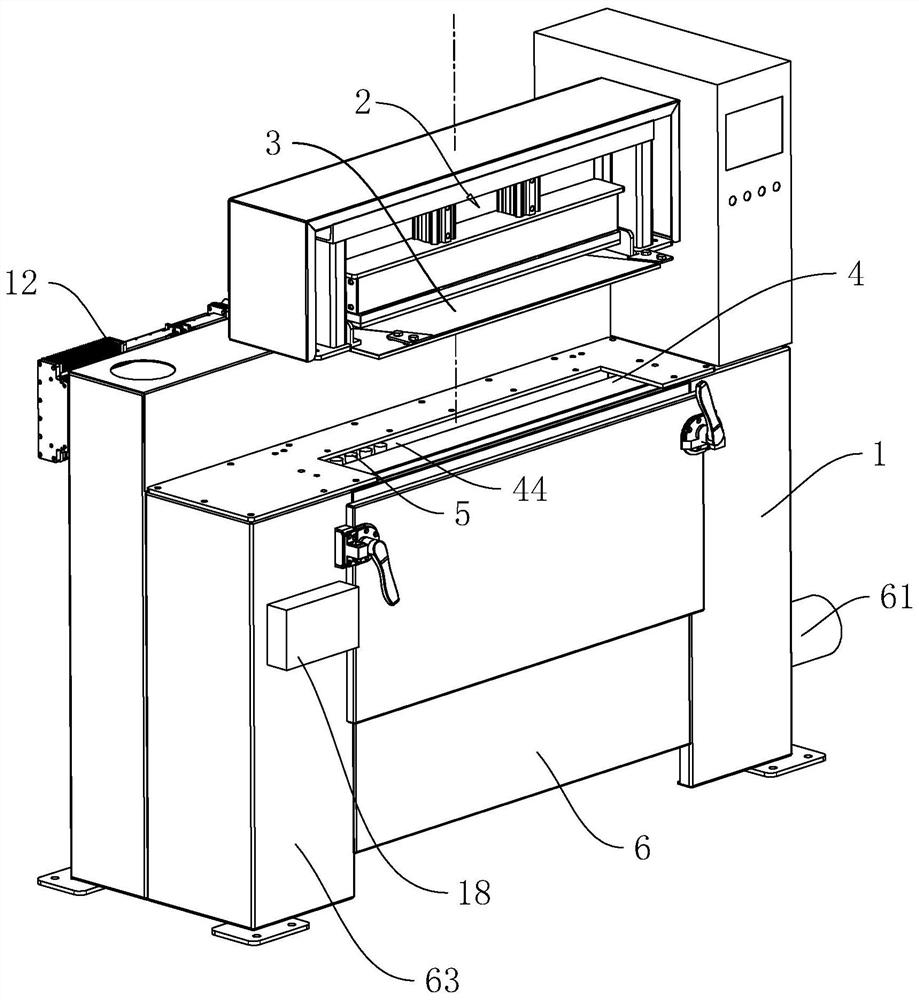

[0038] The embodiment of the present application discloses an abrasive belt blasting device. refer to figure 1 as well as figure 2 , an abrasive belt blasting device includes a body 1, a positioning plate 4 is installed in the body 1, and a sand bar 3 is placed on the positioning plate 4. A sandblasting head 5 is installed below the positioning plate 4, and the sandblasting head 5 is used to spray gravel to the sand bar 3. The positioning plate 4 is provided with a sandblasting port 44 for the gravel to pass through. In order to reduce the possibility of shaking of the sand bar 3, a fixing assembly 2 is installed on the body 1, and the fixing assembly 2 is used to fix the sand bar 3.

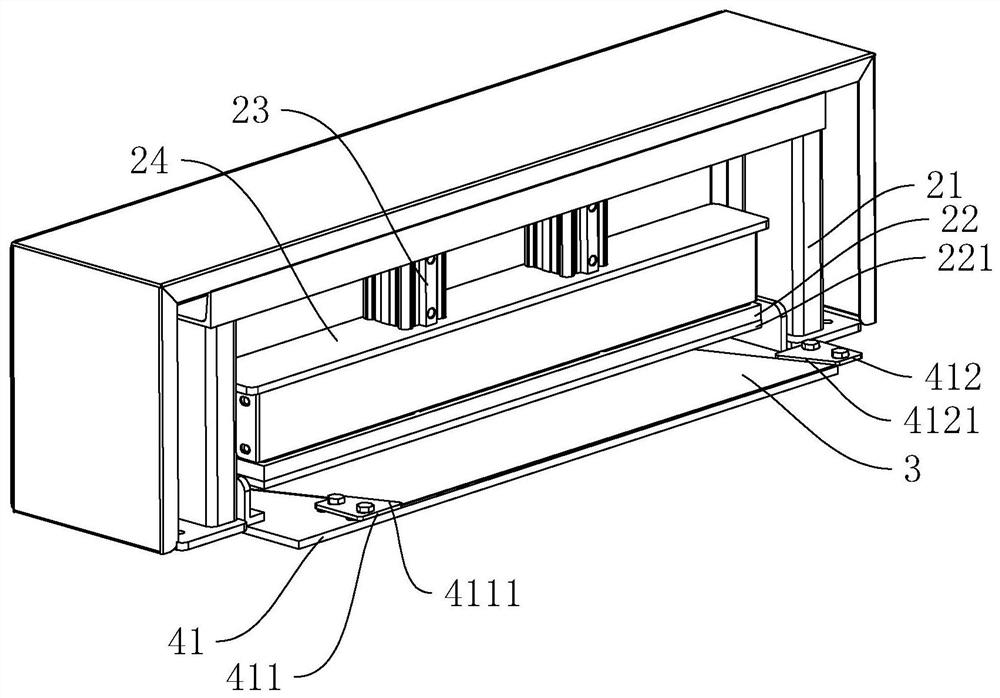

[0039] refer to image 3 , the fixing assembly 2 includes a bracket 21 and a pressing plate 22, and the bracket 21 and the body 1 are fixed by bolts. The support 21 is connected with the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com