Manufacturing method of natural polymer gel artificial muscle assembled through wet bonding

A natural polymer and artificial muscle technology, applied in the field of natural polymer gel artificial muscle production, can solve problems such as environmental pollution, and achieve the effects of reducing cost, simplifying process difficulty, good biodegradability and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

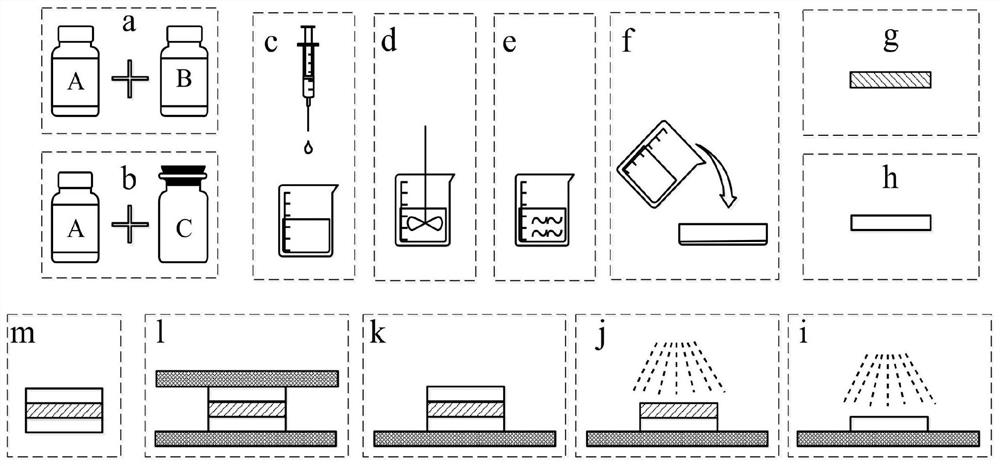

[0016] A kind of natural polymer gel artificial muscle manufacturing method assembled by wet bonding, its specific implementation steps are as follows:

[0017] Step 1: Prepare a natural polymer electric drive membrane cross-linked by sodium carboxymethyl cellulose and carboxylated chitosan; its specific features are: Xg sodium carboxymethyl cellulose and Yg carboxylated chitosan Add the sugar into a beaker with 40ml of deionized water, and then add 2ml of glycerin; use a magnetic stirrer to stir in a water bath, the water temperature is 50°C, and the stirring time is 1h; , each time for 10 minutes, intermittently standing for 10 minutes; after the defoaming is completed, pour the solution into the mold, put the mold in a vacuum dryer at a temperature of 80°C and dry for 3-4 hours to obtain an electrically driven membrane.

[0018] Step 2: P...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap