Terminal anchoring wire clamp mechanism of high-iron copper alloy contact wire

A contact wire and copper alloy technology, which is applied in the field of terminal anchoring clamp mechanism of high-iron copper alloy contact wire, can solve problems such as the gap between splint and contact wire, loose contact wire, and affecting the stability of contact wire fixation, etc., and achieves a wide range of applications , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

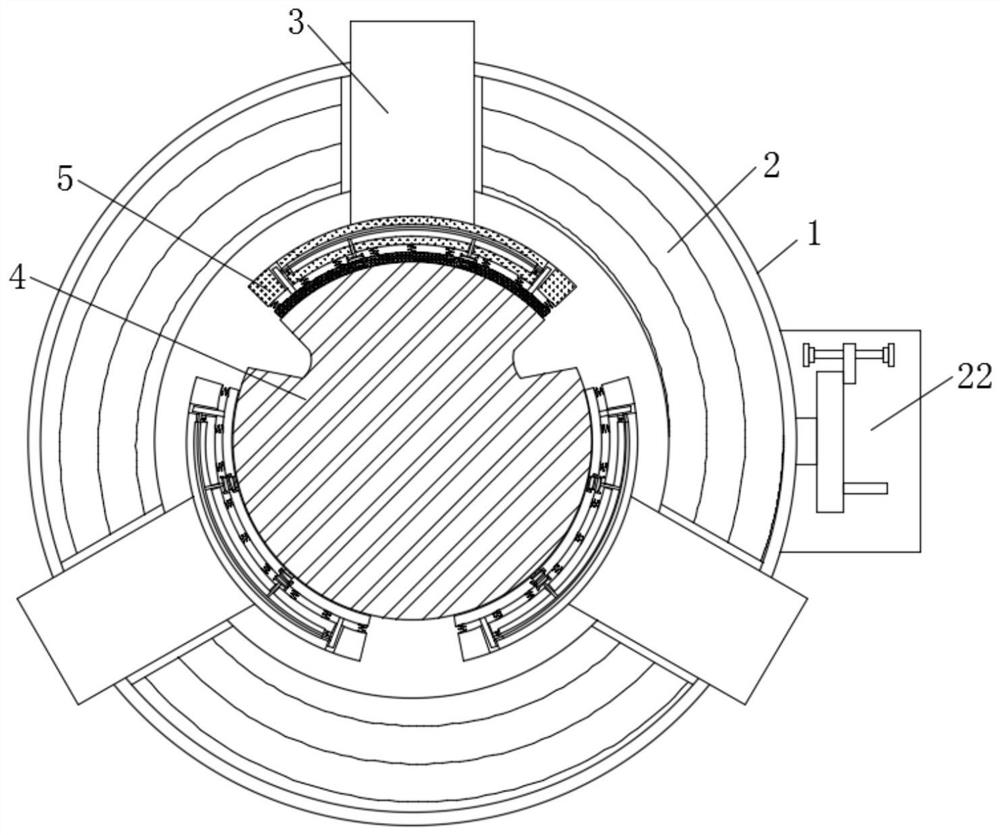

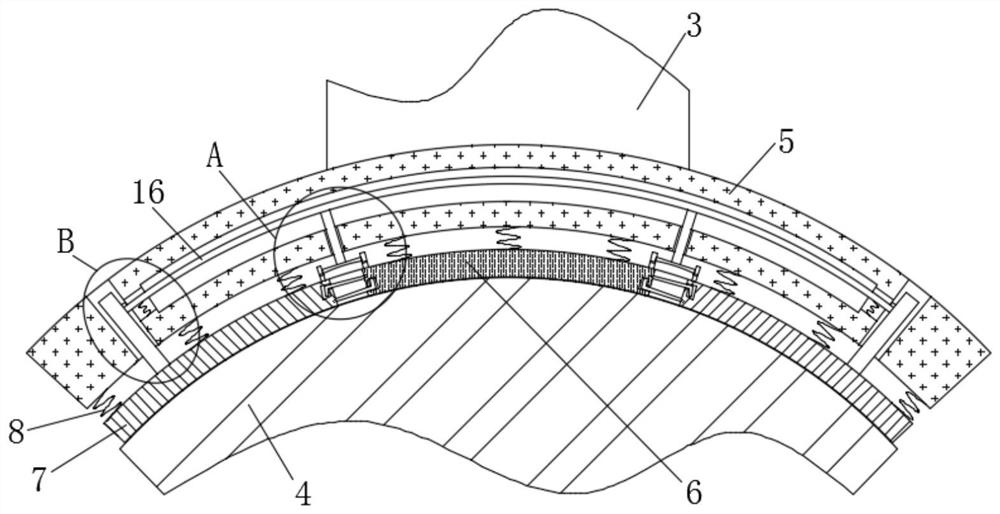

[0031] refer to Figure 1-6 , a terminal anchoring clamp mechanism for high-iron copper alloy contact wires, including a housing 1, a three-jaw chuck 2 is fixedly installed on the housing 1, a contact wire body 4 runs through the middle of the three-jaw chuck 2, and the three-jaw chuck 2. Several sliders 3 are installed on the front end, and the end of the slider 3 close to the contact line body 4 is fixedly equipped with a fixed splint 5, and the middle part of the side of the fixed splint 5 close to the contact line body 4 is provided with a movable splint 6. Two movable splints 7 are symmetrically arranged on both sides of splint one 6, and one end of movable splint one 6 and movable splint two 7 close to the contact wire body 4 is fitted with the contact wire body 4, and the fixed splint 5 is close to the contact wire body 4 One end is provided with a plurality of springs 8, and the other ends of the springs 8 are respectively fixedly connected to movable splint 1 6 and mo...

Embodiment 2

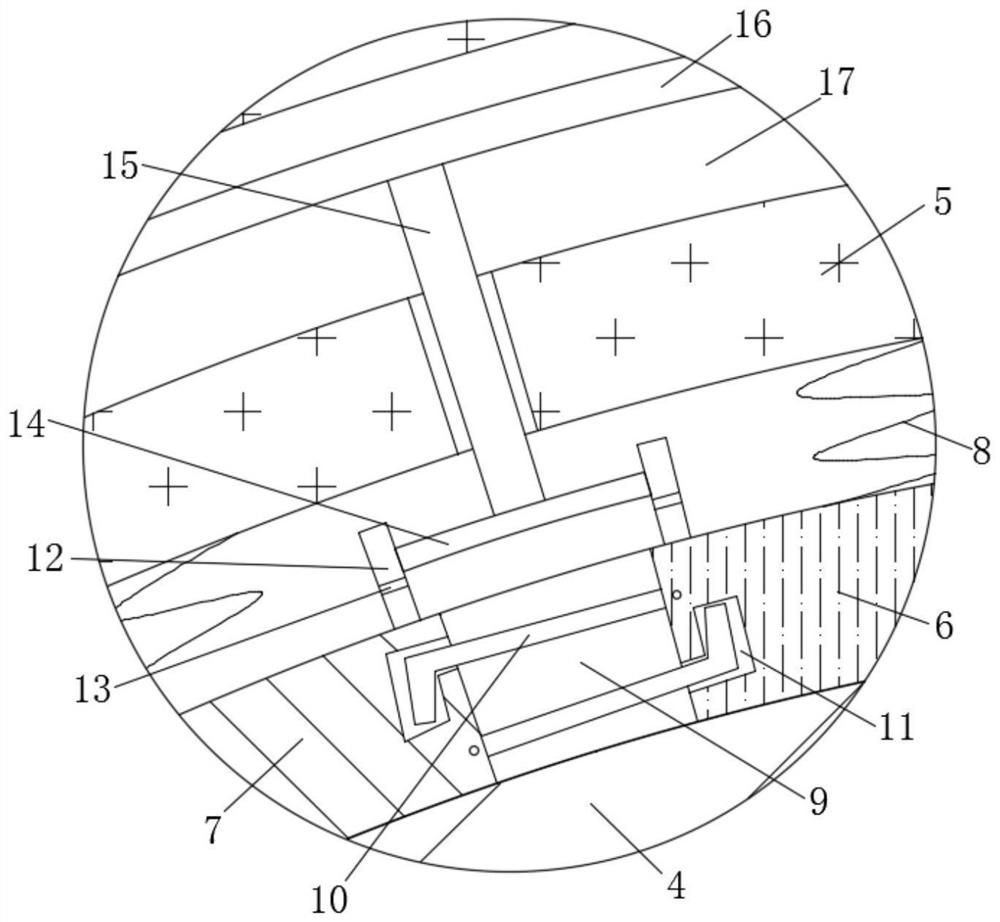

[0034] refer to Figure 1-6 , in this embodiment, it is basically the same as Embodiment 1, and more optimally, a through groove 9 is provided at the connection between the two ends of the movable splint 6 and the movable splint 2 7, and there are two through groove 1 9 The adjustment clamp 10, the ends of the adjustment clamps 10 on both sides that are far away from each other are respectively hinged with the movable splint one 6 and the movable splint two 7, and the one end of the movable splint one 6 and the movable splint two 7 that are close to each other corresponds to the adjustment card The rods 10 are all provided with a card slot 11, and the adjustment bar 10 is movably connected to the card slot 11;

[0035] During use, the set through groove one 9, the adjustment lever 10 and the draw groove 11 are convenient to make the bending angle between the movable splint one 6 and the movable splint two 7 carry out self-adaptive adjustment according to the actual size of the...

Embodiment 3

[0037] refer to Figure 1-6, in this embodiment, it is basically the same as Embodiment 1, and more optimally, a sealing plate 12 is fixedly installed on the end of the movable splint 6 and the movable splint 7 away from the contact wire body 4, and there are several openings on the sealing plate 12. The through hole 13, the sealing plate 12 is inserted with a piston 14, the end of the piston 14 away from the contact wire body 4 is fixedly connected with a connecting rod 15, and the end of the connecting rod 15 away from the contact wire body 4 is fixedly installed with a connecting piece 16, Corresponding connecting piece 16 and connecting rod 15 inside described fixing splint 5 are all provided with through groove 2 17, and connecting rod 15 and connecting piece 16 are movably connected fixing splint 5, and described connecting piece 16 is close to one end both sides of contact line body 4. A spring two 18 is fixedly connected, and the other end of the spring two 18 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com