Drilling sampling device for geological exploration

A technology of geological exploration and sampling device, which is applied in the direction of sampling device, etc., can solve the problems of difficulty in taking out samples, poor stability, increased staff burden, etc., and achieves the effect of improving stability and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

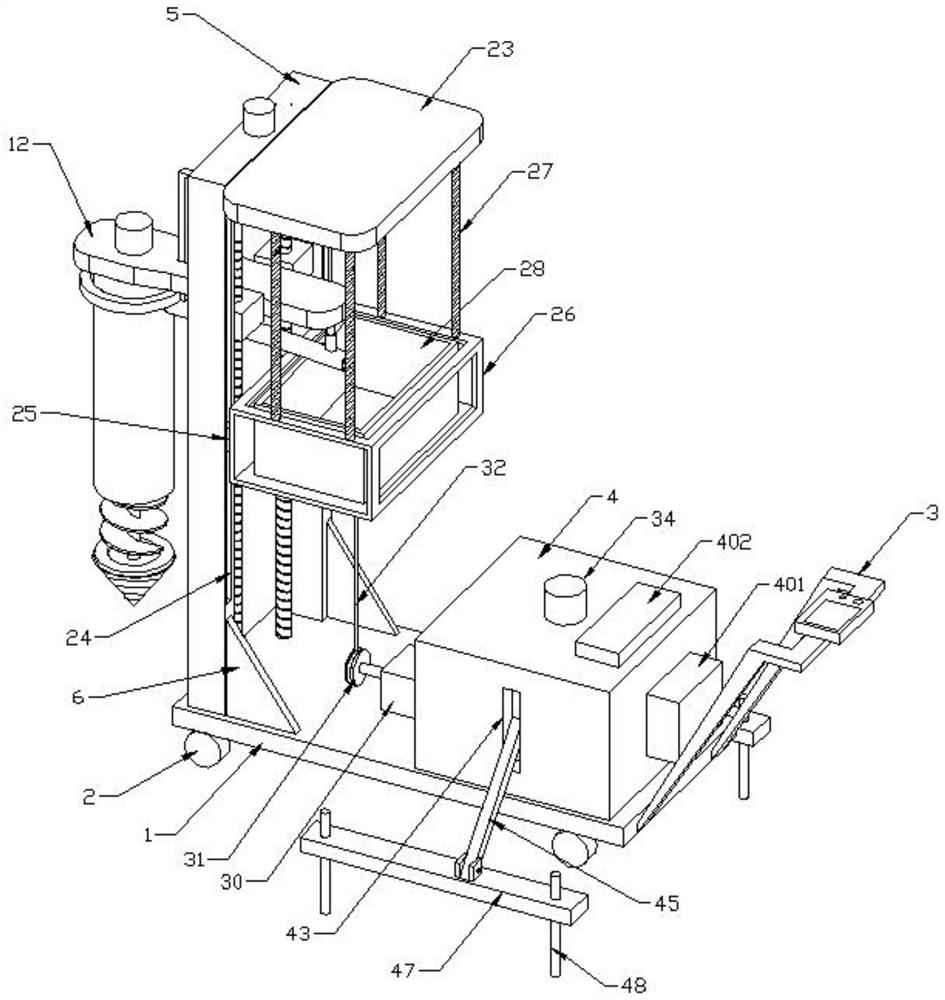

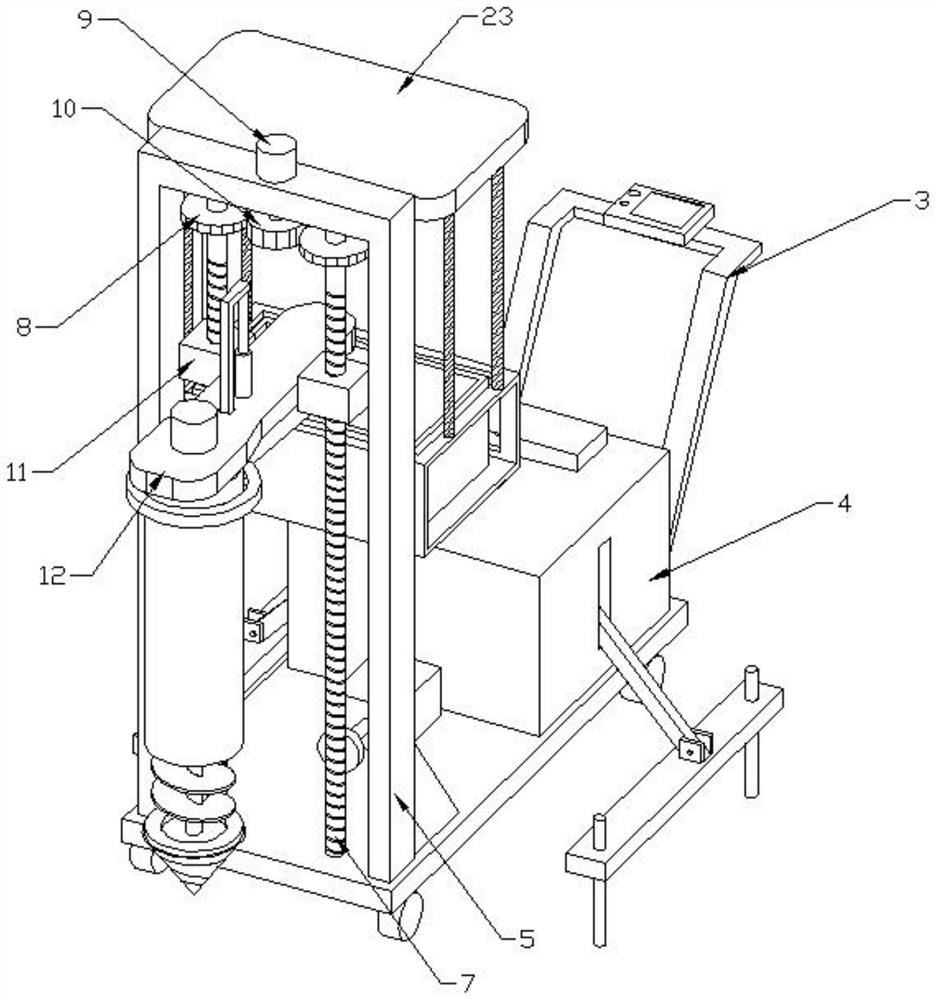

[0027] see Figure 1-7 As shown, this embodiment is a drilling and sampling device for geological exploration, including a base 1, the four corners of the bottom of the base 1 are equipped with moving wheels 2, the right side wall of the base 1 is connected with a push rod 3, and the upper end of the push rod 3 is connected with a control wheel. The panel, the top right side of the base 1 is connected with the outer shell 4, the top left side of the base 1 is connected with the guide frame 5, the guide frame 5 is arranged in a U-shaped structure, and the vertical end of the guide frame 5 is welded with a reinforcing rib on the top of the base 1 6. There are two screw rods 7 connected in rotation between the transverse end of the guide frame 5 and the base 1, the driven gear 8 is connected to the top of the outer wall of the screw rod 7, the drive motor 9 is connected to the top of the transverse end of the guide frame 5, and the drive motor 9 The power output end of the bottom...

Embodiment 2

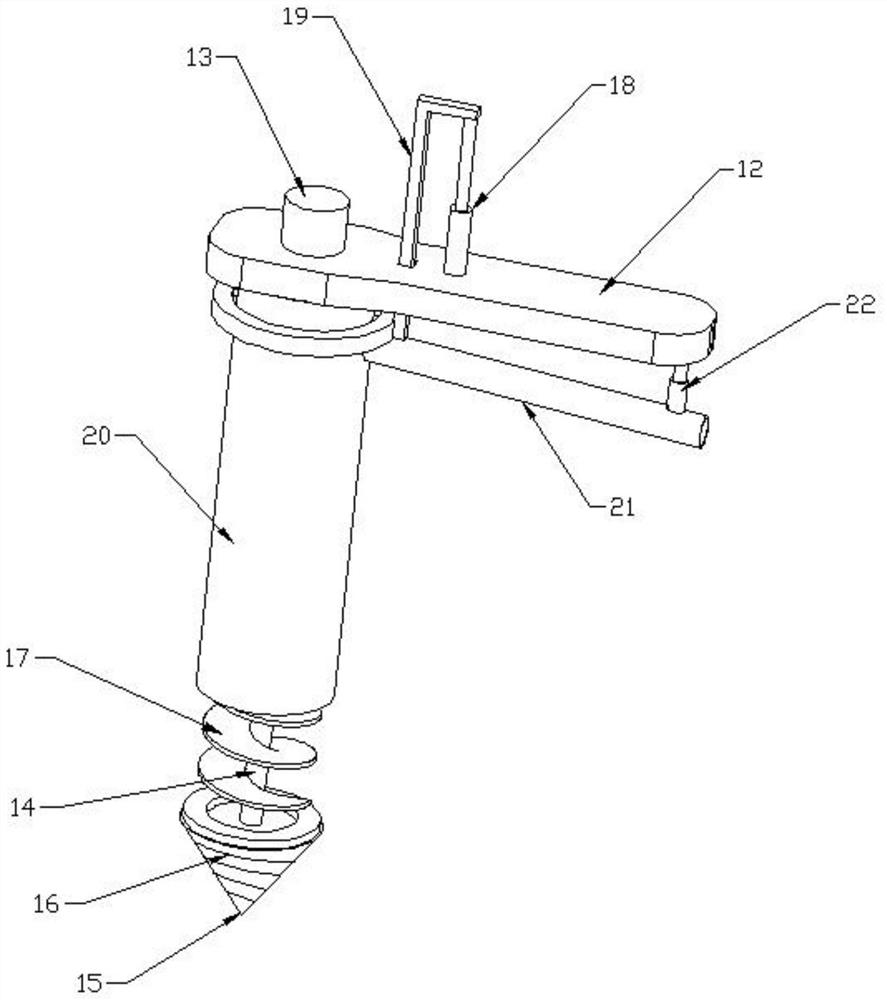

[0033] On the basis of Embodiment 1, the top left side of the drilling base 12 is connected with a drilling motor 13, the bottom power output end of the drilling motor 13 is connected with a drill rod 14, and the bottom of the drill rod 14 is connected with a conical head 15. The outer wall of the shaped head 15 is connected with a tapered drill edge 16, the top of the tapered head 15 is connected with a washer, the outer wall of the drill rod 14 is connected with an auger 17, the top of the drilling seat 12 is connected with an electric telescopic rod 18, and the electric telescopic rod 18 The movable end of the installation frame 19 is connected with a mounting frame 19, and the lower end of the mounting frame 19 is connected with a limit sleeve 20. The limit sleeve 20 is movably set outside the auger 17, and the right end of the limit sleeve 20 is connected with a discharge pipe 21. A free telescopic rod 22 is connected between the top right side of the material pipe 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com