Spoke wheel design method

A design method and spoke technology, applied in special data processing applications, geometric CAD, etc., can solve the problem that the shape parameters and scope of spoke wheels are no longer applicable, and achieve the effect of good fatigue strength performance and optimal weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for designing a spoked wheel, comprising the steps of:

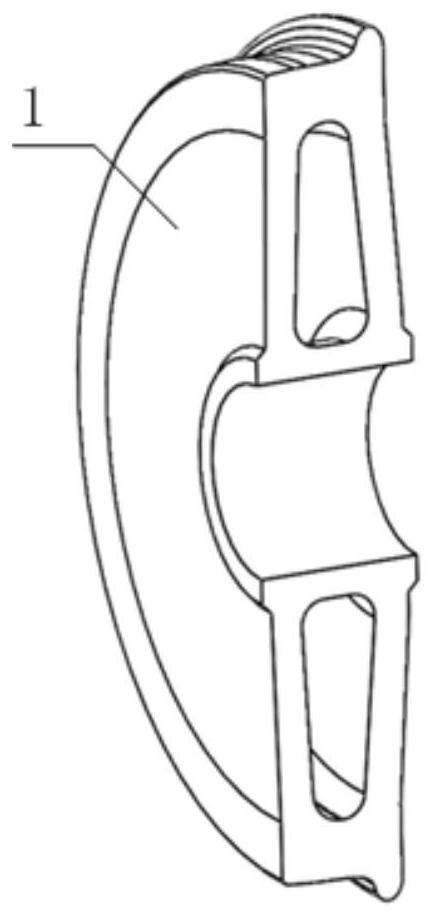

[0054] (1) The diameter of the rolling circle of the designed railway wheel is 840mm, and the inner radius of the rim is R w 361mm, hub outer radius R g The height of the hub hole is 100mm, the height of the hub hole is 175mm, and the axle load of the wheel set is 14 tons. Using DesinModeler of ANSYS Workbench, an internal and external closed cavity wheel model is established according to the size of the wheel rim and hub. figure 1 shown.

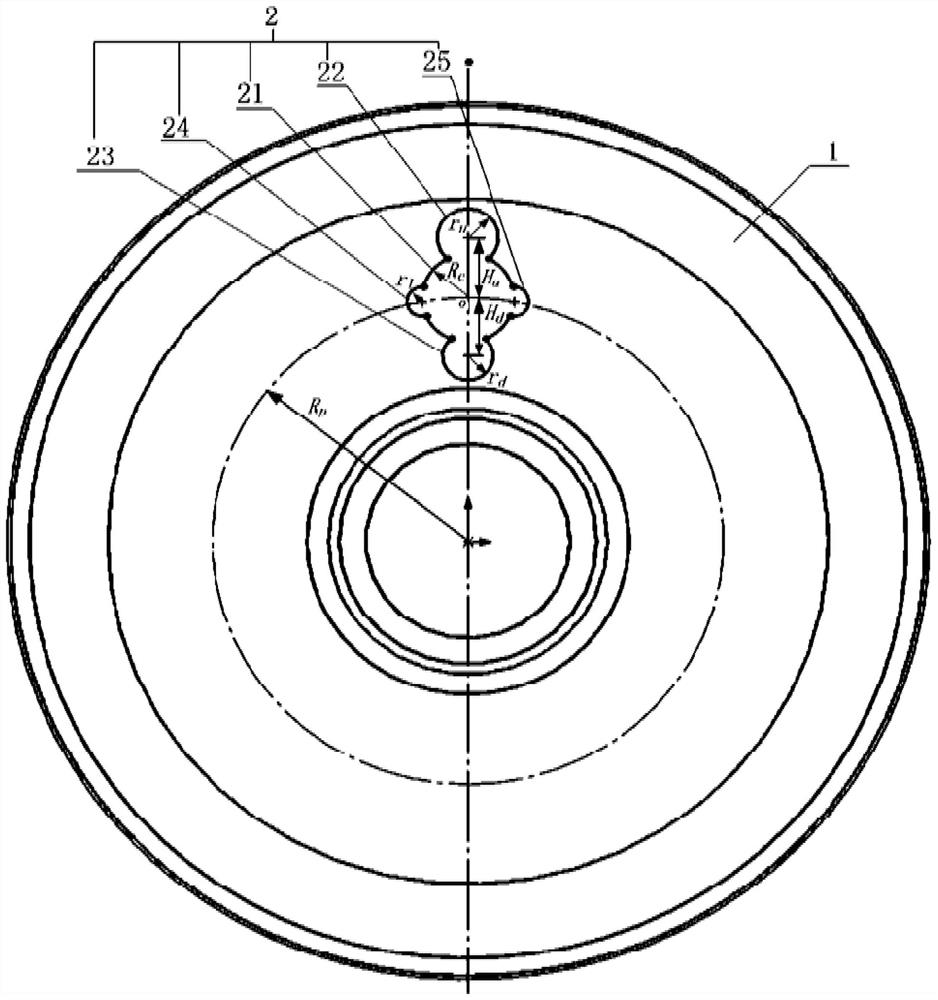

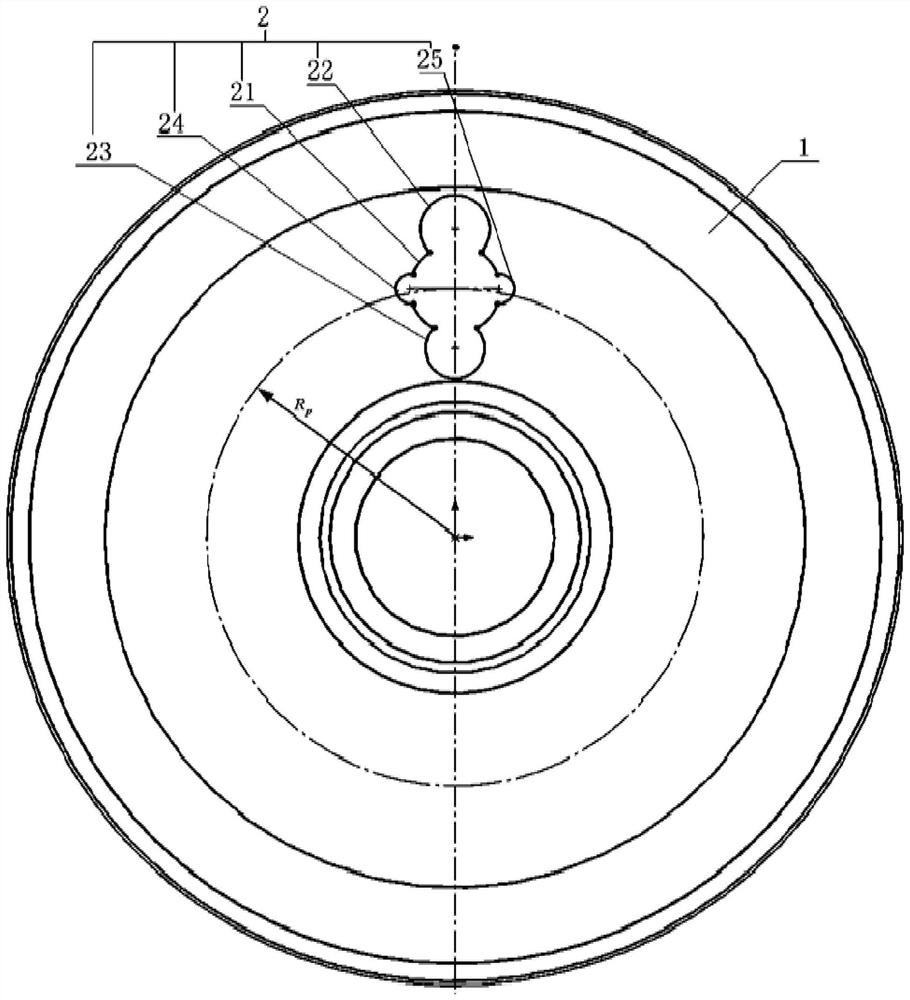

[0055] (2) if figure 2 As shown, the primary spoke hole 2 is drawn on the cavity wheel model 1. The primary spoke hole 2 consists of a central arc 21, an upper arc 22 positioned at the upper end of the central arc 21, a lower arc 23 positioned at the lower end of the central arc 21, and The left arc 24 and the right arc 25 respectively located on the left and right sides of the central arc 21 are formed; p on the arc line of 600.5mm; the center arc 21, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com