Low-resistance high-efficiency conductor processing method

A processing method and low-resistance technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., to achieve the effect of reducing DC resistivity, saving a lot of resources, and reducing the consumption of heating resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

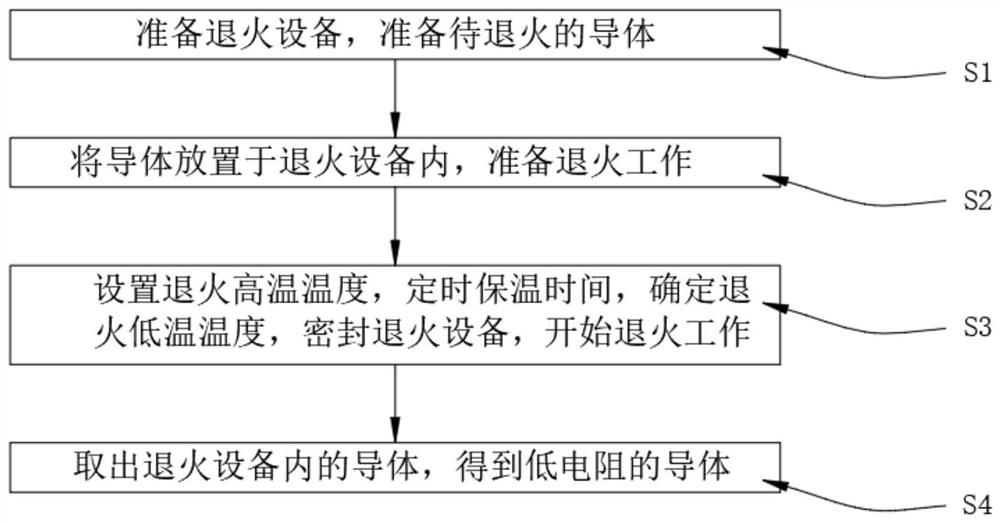

[0031] see Figure 1-2 , the present invention provides a technical solution: a low-resistance high-efficiency conductor processing method, comprising the following steps:

[0032] S1. Prepare annealing equipment and conductors to be annealed;

[0033] S2. Place the conductor in the annealing equipment and prepare for the annealing work;

[0034] S3. Set the annealing high temperature, set the holding time, determine the annealing low temperature, seal the annealing equipment, and start the annealing work;

[0035] S4, taking out the conductor in the annealing device to obtain a conductor with low resistance;

[0036] The direct current resistivity is greatly reduced, which can meet people's demand for the direct current resistance of the conductor. This method improves the production efficiency of the alloy strand, reduces the scrap rate, greatly increases the production capacity of the alloy strand, ensures the stability of the process, and improves the production efficien...

Embodiment 2

[0053] see Figure 1-2 , the present invention also provides a technical solution, which is different from the first embodiment: a low-resistance high-efficiency conductor processing method, comprising the following steps:

[0054] S1. Prepare annealing equipment and conductors to be annealed;

[0055] S2. Place the conductor in the annealing equipment and prepare for the annealing work;

[0056]S3. Set the annealing high temperature, set the holding time, determine the annealing low temperature, seal the annealing equipment, and start the annealing work. The annealing high temperature of the conductor is 450°C, the holding time is 60min, and the annealing low temperature is 30°C;

[0057] When the annealing work is carried out, the following detection steps are included:

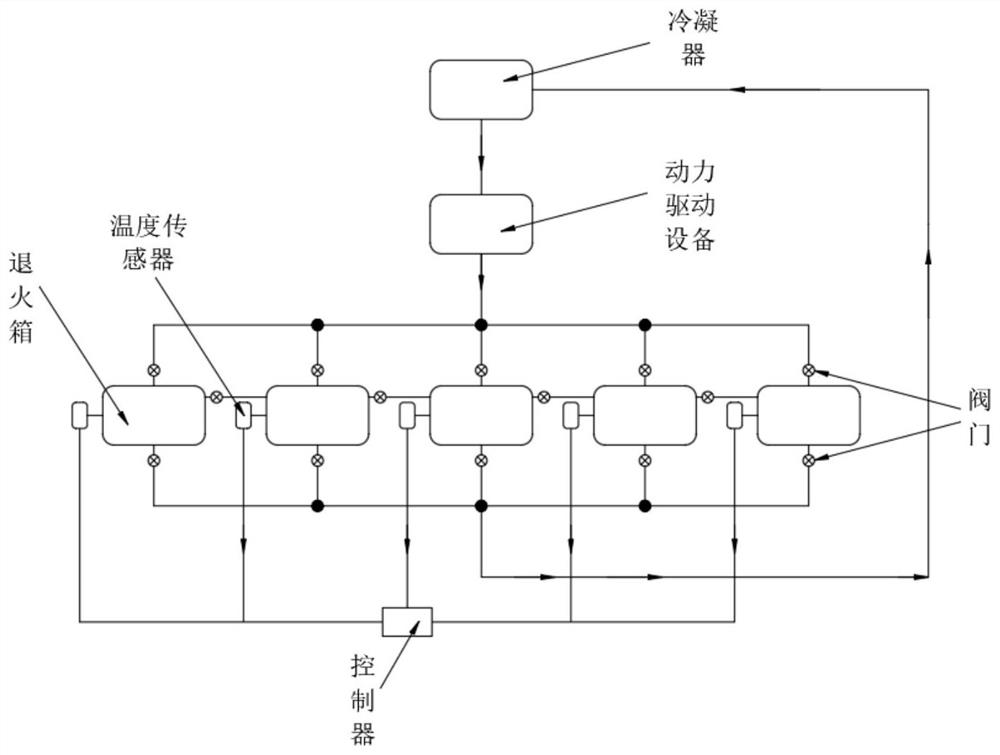

[0058] S31. The temperature sensor detects the current temperature in the annealing box, and sends the signal to the controller, and the controller records the current temperature in the annealing box;

...

Embodiment 3

[0065] see Figure 1-2 , the present invention also provides a technical solution, which is different from the first embodiment: a low-resistance high-efficiency conductor processing method, comprising the following steps:

[0066] S1. Prepare annealing equipment and conductors to be annealed;

[0067] S2. Place the conductor in the annealing equipment and prepare for the annealing work;

[0068] S3. Set the annealing high temperature, set the holding time, determine the annealing low temperature, seal the annealing equipment, and start the annealing work. The annealing high temperature of the conductor is 460°C, the holding time is 55min, and the annealing low temperature is 30°C;

[0069] When the annealing work is carried out, the following detection steps are included:

[0070] S31. The temperature sensor detects the current temperature in the annealing box, and sends the signal to the controller, and the controller records the current temperature in the annealing box; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com