Chip packaging machine and method of use

A technology of chip packaging and stacking machine, which is applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., and can solve the problems of low efficiency of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

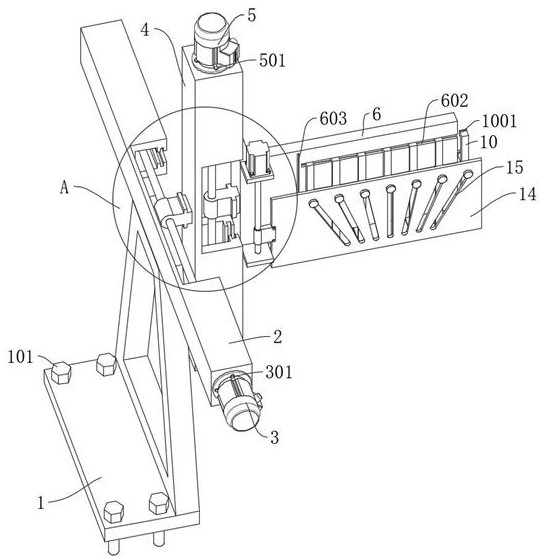

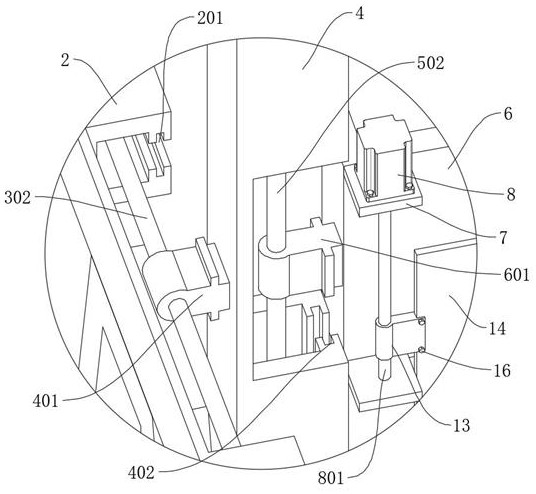

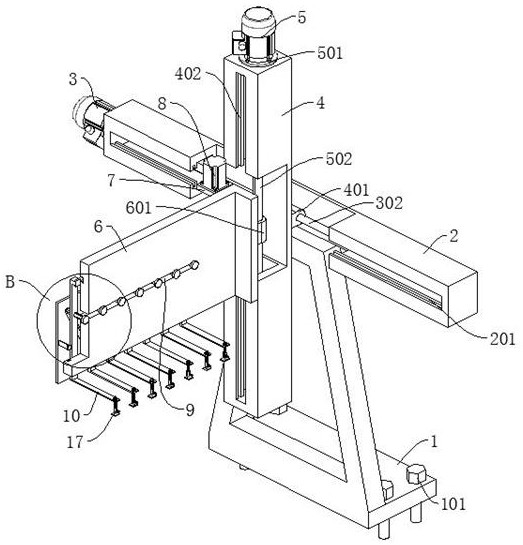

[0042] Example 1: Reference Figure 1-13 A chip arranging machine for chip packaging comprises a supporting seat 1, a fixing plate 6, a placing seat 7, and a third motor 8 fixedly connected to the placing seat 7; A third screw 801 fixedly connected to the output end of the third motor 8; The clamp 13 is screwed on the third screw 801; An adjusting plate 14 detachably connected to the holder 13; The l-shaped adjusting lever 10 is slidably connected to the fixed plate 6; A vacuum chuck 17 detachably connected to the L-shaped adjusting rod 10; The fixing rod 11 is fixedly connected to the L-shaped adjusting rod 10; A roller 12 rotatably connected to the fixing rod 11; The adjusting plate 14 is slidably connected to the fixed plate 6, which is provided with a first adjusting groove 9, and the adjusting plate 14 is provided with a plurality of second adjusting grooves 15, and the second adjusting grooves 15 on both sides of the adjusting plate 14 are of inclined design, and the two fixi...

Embodiment 2

[0051] Example 2: Reference Figure 1-13 A chip arranging machine for chip packaging comprises a supporting seat 1, a fixing plate 6, a placing seat 7, and a third motor 8 fixedly connected to the placing seat 7; A third screw 801 fixedly connected to the output end of the third motor 8; The clamp 13 is screwed on the third screw 801; An adjusting plate 14 detachably connected to the holder 13; The l-shaped adjusting lever 10 is slidably connected to the fixed plate 6; A vacuum chuck 17 detachably connected to the L-shaped adjusting rod 10; The fixing rod 11 is fixedly connected to the L-shaped adjusting rod 10; A roller 12 rotatably connected to the fixing rod 11; The adjusting plate 14 is slidably connected to the fixed plate 6, which is provided with a first adjusting groove 9, and the adjusting plate 14 is provided with a plurality of second adjusting grooves 15, and the second adjusting grooves 15 on both sides of the adjusting plate 14 are of inclined design, and the two fixi...

Embodiment 3

[0060] Example 3: Reference Figure 1 、 Figure 3 and Figure 4 A chip arranging machine for chip packaging comprises a supporting seat 1, a fixing plate 6, a placing seat 7, and a third motor 8 fixedly connected to the placing seat 7; A third screw 801 fixedly connected to the output end of the third motor 8; The clamp 13 is screwed on the third screw 801; An adjusting plate 14 detachably connected to the holder 13; The l-shaped adjusting lever 10 is slidably connected to the fixed plate 6; A vacuum chuck 17 detachably connected to the L-shaped adjusting rod 10; The fixing rod 11 is fixedly connected to the L-shaped adjusting rod 10; A roller 12 rotatably connected to the fixing rod 11; The adjusting plate 14 is slidably connected to the fixed plate 6, which is provided with a first adjusting groove 9, and the adjusting plate 14 is provided with a plurality of second adjusting grooves 15, and the second adjusting grooves 15 on both sides of the adjusting plate 14 are of inclined des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com