Upper material ejecting device of hot die forging press machine

A technology of hot die forging presses and ejector devices, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, heating/cooling equipment, etc. Thickness positioning, product offset and other issues to achieve the effect of increasing stability and service life, improving service life and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

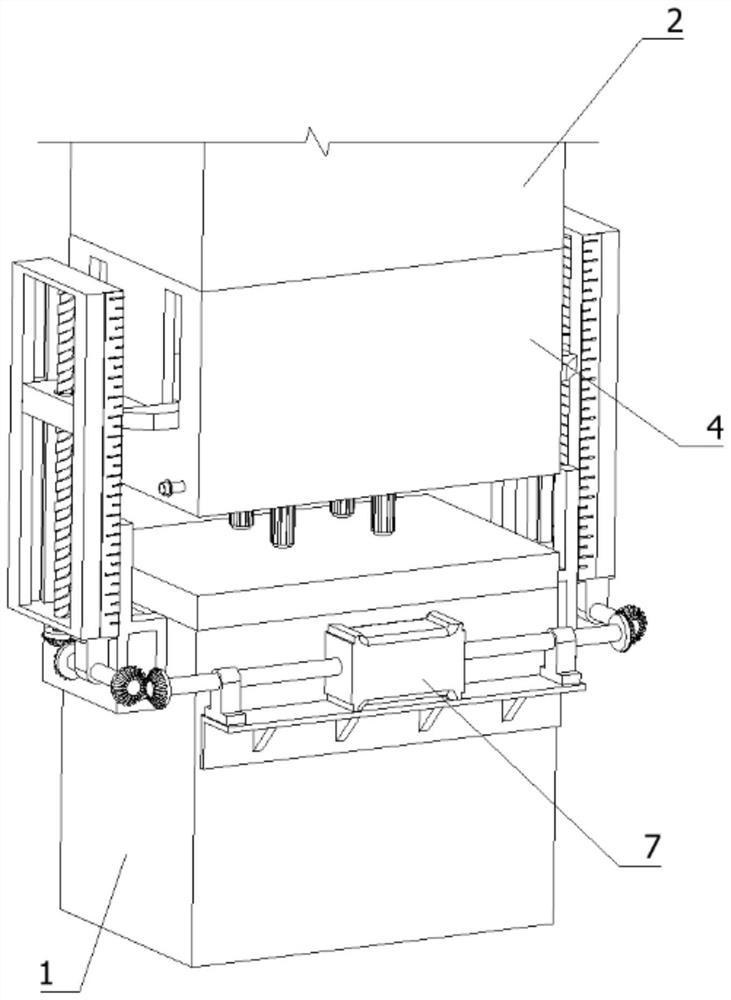

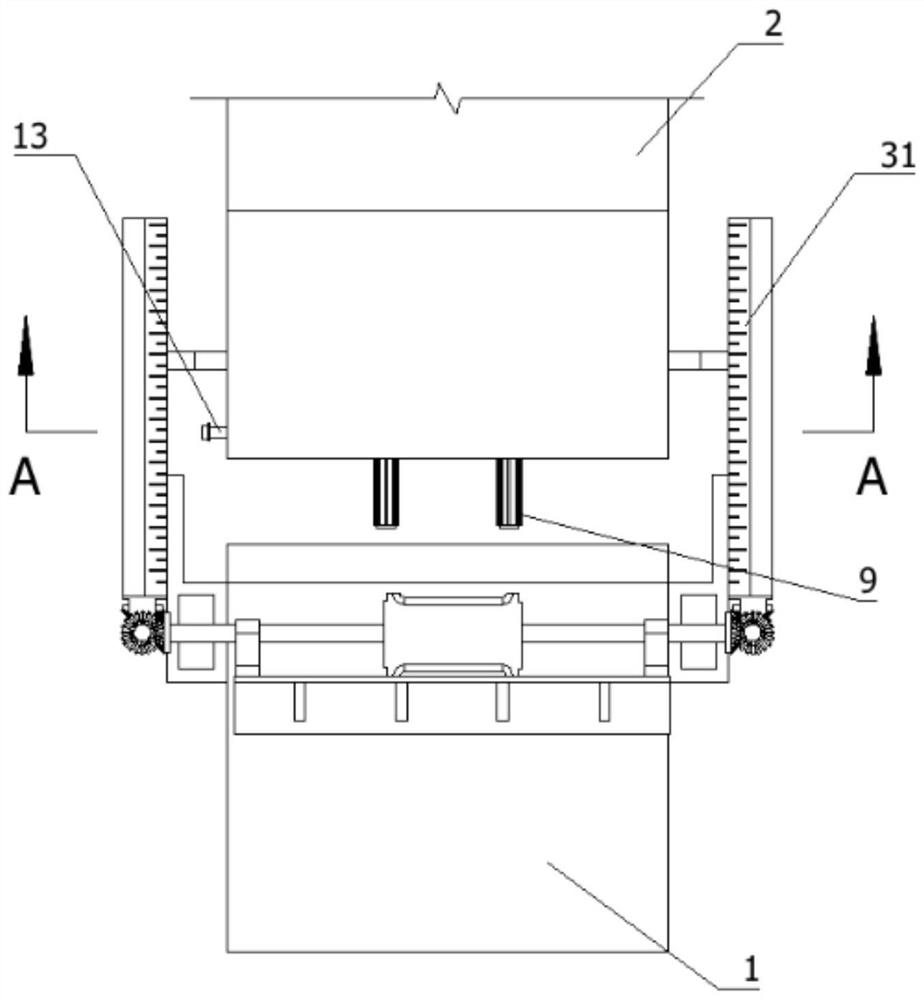

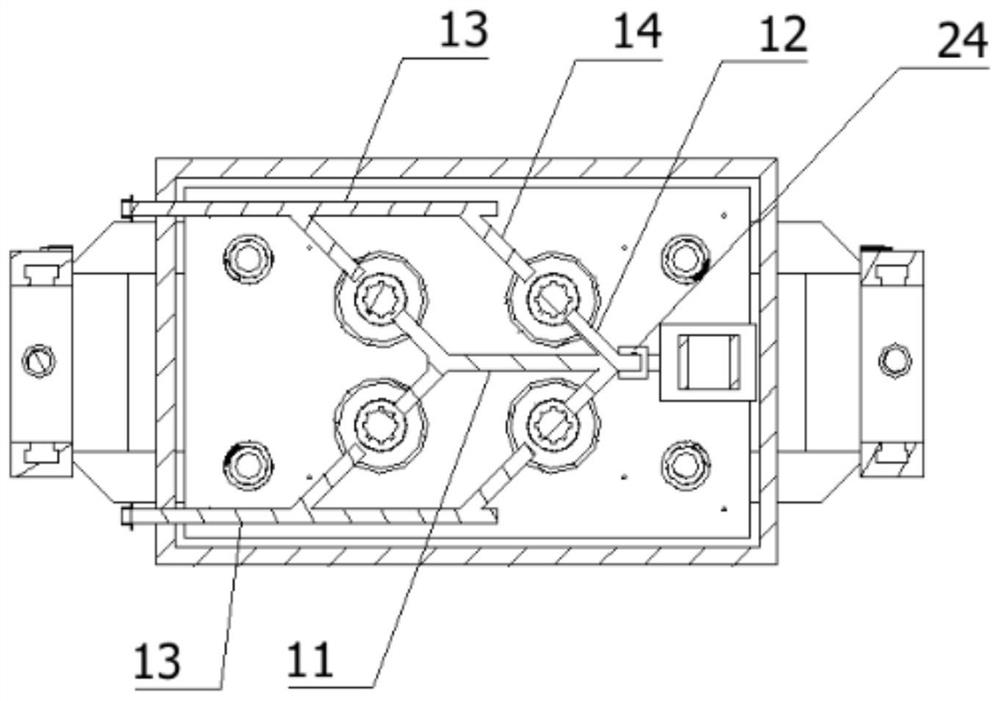

[0058] In order to solve the technical problem of how to position the product and prevent the product from bonding with the formwork 3 and how to improve the service life of the ejector column, such as Figure 1 to Figure 5 As shown, the following technical solutions are provided:

[0059] A loading and ejecting device for a hot die forging press, comprising a frame 1, a slider 2 positioned directly above the frame 1, a mold frame 3 arranged at the bottom of the slider 2, and further comprising:

[0060] The upper ejection mechanism 4 is arranged between the slider 2 and the mold frame 3;

[0061] The cooling anti-blocking mechanism 5 is arranged inside the upper ejection mechanism 4;

[0062] The ejectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com