Curing device and method for 3D printing dental cast

A curing device and 3D printing technology, applied in the field of 3D printing, can solve the problems of defective objects, curing, inconvenient use, etc., and achieve the effect of improving adequacy and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

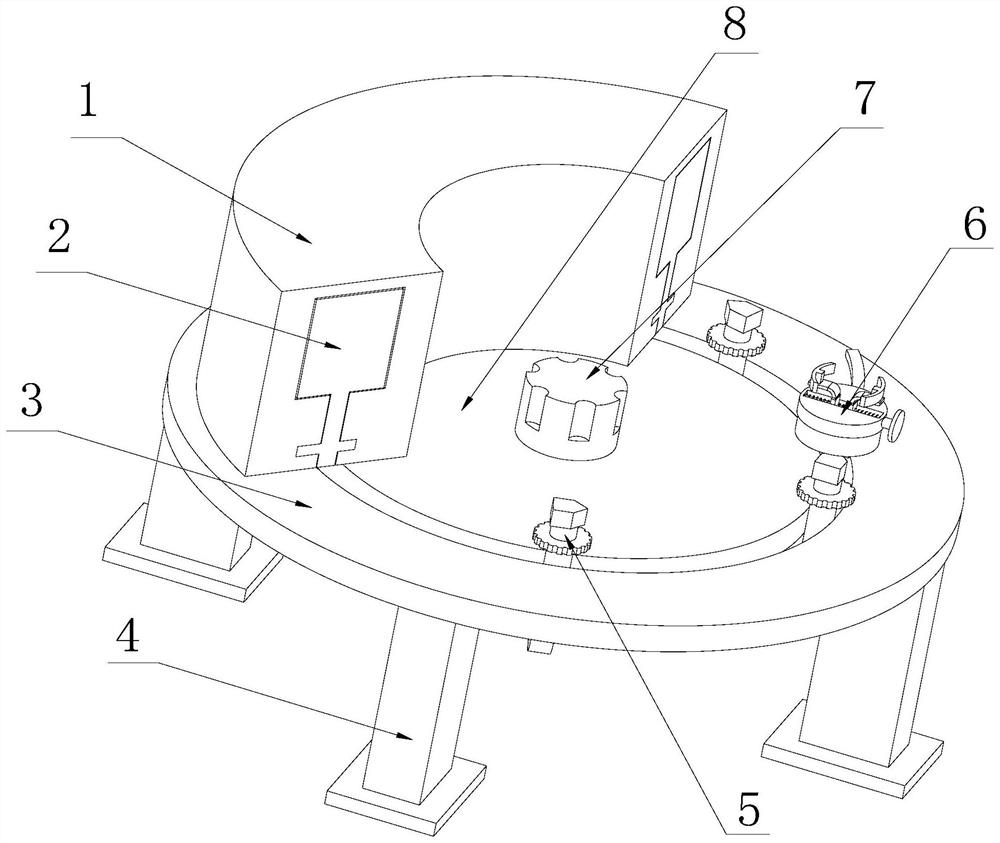

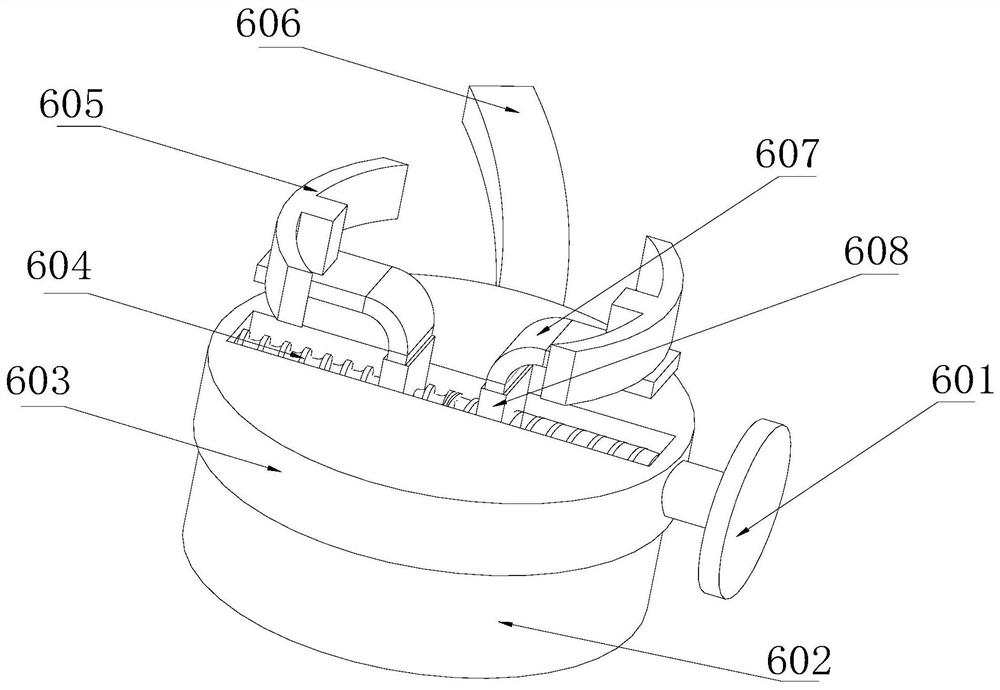

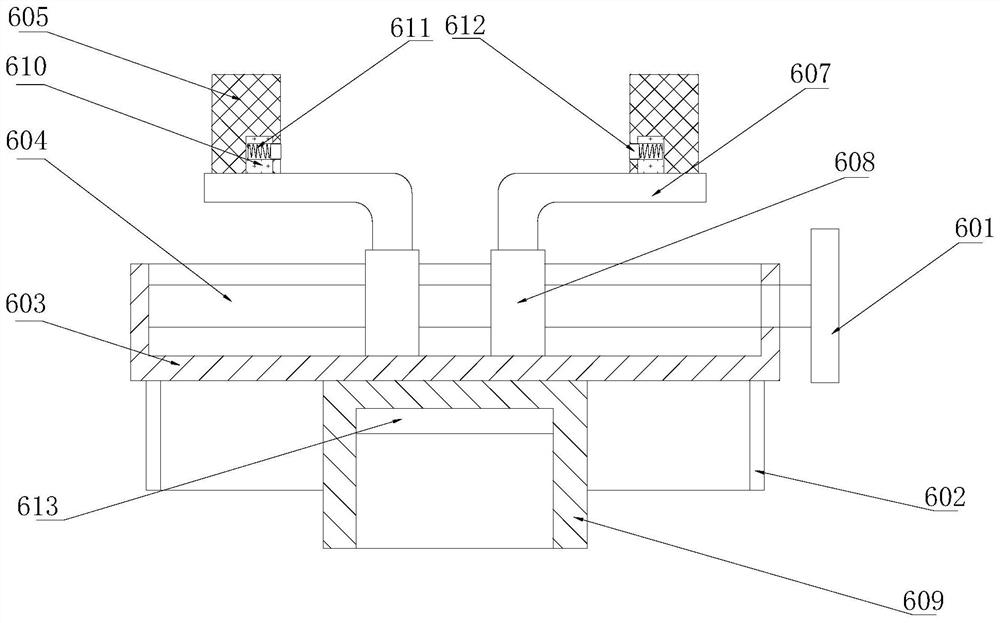

[0037] Such as Figure 1-Figure 5 As shown, a curing device for 3D printing dental molds includes a circular block 8, a motor 7 is installed on the top outer wall of the circular block 8, and a rotating shaft 11 is installed on the bottom outer wall of the output shaft of the motor 7, and the bottom outer wall of the rotating shaft 11 A placement block 9 is installed, and the outer wall of the bottom of the placement block 9 is equipped with arc-shaped frames 10 equidistantly distributed, and an arc-shaped cover 1 is installed on one side of the outer wall of the top of the circular block 8, and a fixed ring 3 is installed on the outer wall of the bottom of the arc-shaped cover 1 , the top of the arc frame 10 is provided with a rotating mechanism 5, and the top of the circular block 8 is provided with equidistantly distributed fixing mechanisms 6;

[0038] The rotating mechanism 5 comprises a circular shaft 501 that rotates on the top outer wall of the arc frame 10, and the to...

Embodiment 2

[0051] Based on the curing device for 3D printing dental models provided in the first embodiment of the present application, the second embodiment of the present application proposes another curing device for 3D printing dental models. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0052] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0053] Such as Figure 1-Figure 7 As shown, a curing device for 3D printing dental molds includes a purification housing 17 installed on the outer wall of the top of the arc-shaped cover 1, and an air pump 16 is installed on the outer wall of one side of the purification housing 17, and an air pump 16 is installed on the input end of the air pump 16. Air outlet pipe 15, the other side outer wall of arc cover...

Embodiment 3

[0055] Based on the curing device for 3D printing dental models provided in the first embodiment of the present application, the third embodiment of the present application proposes another curing device for 3D printing dental models. The third embodiment is only a preferred manner of the first embodiment and the second embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment and the second embodiment.

[0056] The third embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0057] Such as Figure 1-Figure 8 As shown in the figure, a curing device for 3D printing dental molds includes support grooves distributed equidistantly on the outer wall of one side of the arc-shaped extruded plate 605, and the inner wall of the support groove is slidably connected with a support rod 24, and the support rod 24- A rubber head 26 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com