Sand table forming dynamic slicing method based on three-dimensional data driving

A technology of three-dimensional data and slicing, applied in the field of 3D printing, can solve the problems of time-consuming and cumbersome processing, different types of ground objects cannot be represented more delicately and realistically, and materials with different physical properties cannot be mixed and used. Delicate description, high precision, and the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the accompanying drawings required in the embodiments. Obviously, the accompanying drawings in the following description are only some of the present invention. Embodiments, for those of ordinary skill in the art, other drawings can also be obtained based on these drawings without any creative effort.

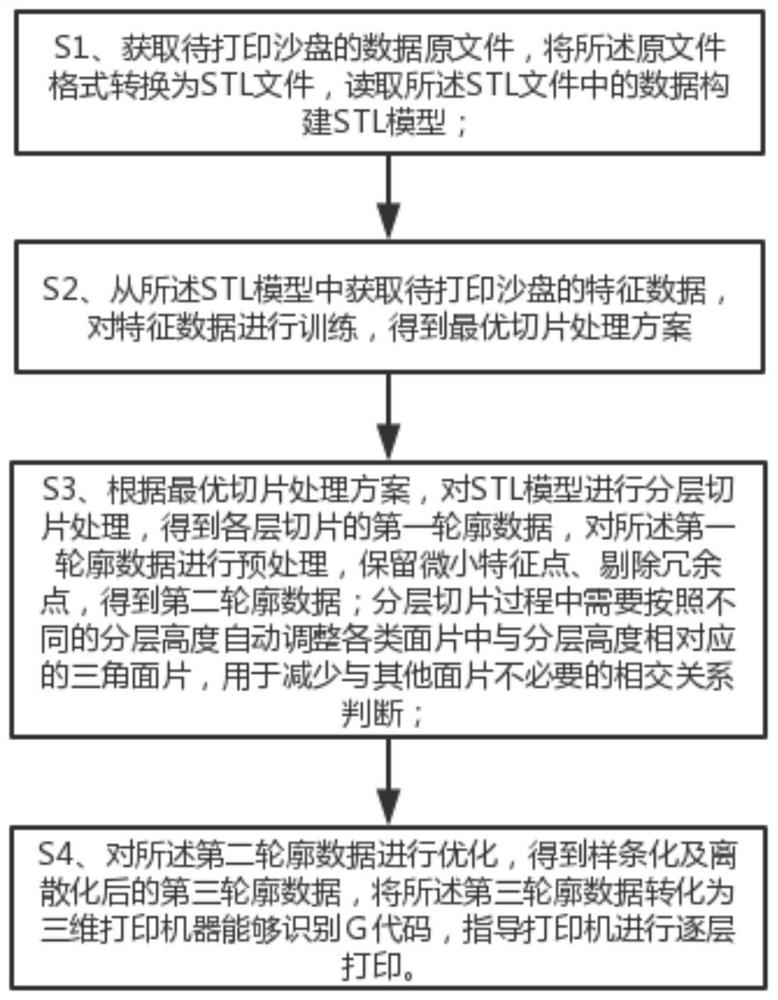

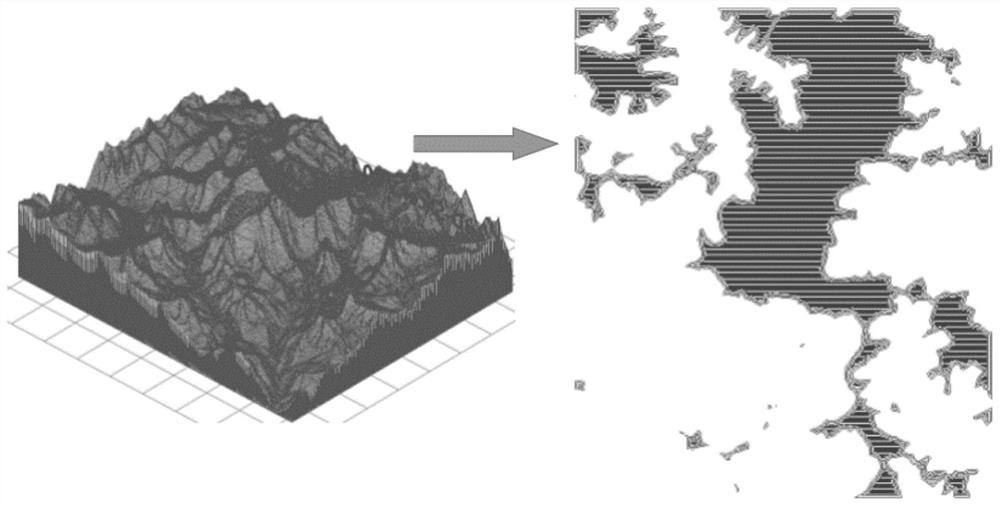

[0033] Such as Figure 1-2 As shown, the present invention discloses a dynamic slicing method based on three-dimensional data-driven sand table forming, comprising the following steps:

[0034] S1. Obtain the original data file of the sand table to be printed, convert the original file format into an STL file, and read the data in the STL file to construct an STL model;

[0035] S2. Obtain the characteristic data of the sand table to be printed in the STL model, train the characteristic data, and obtain the optima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com