Grain leveling robot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

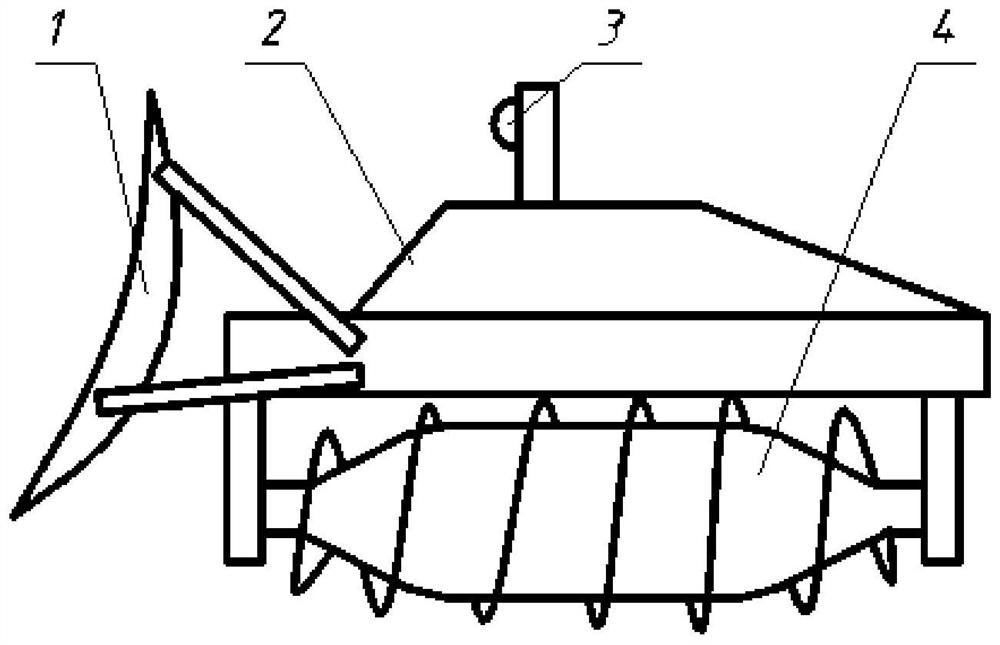

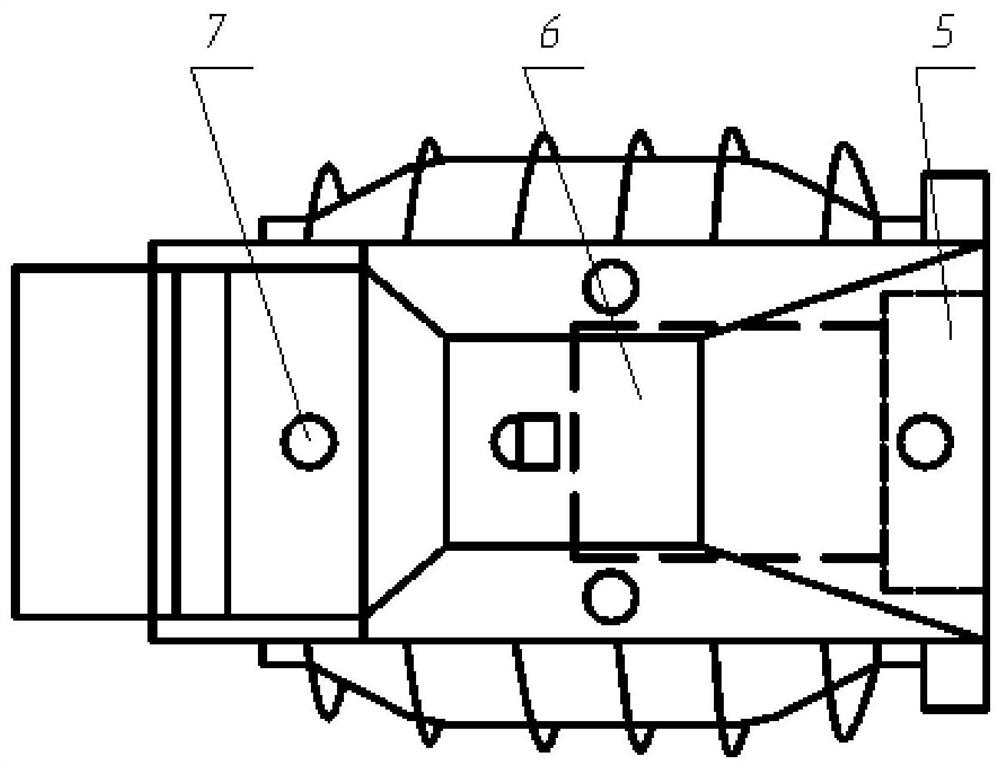

[0063] figure 1 A side view of the flat grain robot of the present embodiment is shown; figure 2 A top view of the flat grain robot of this embodiment is shown.

[0064] Such as figure 1 , figure 2 As shown, the fuselage 2 of the flat-grain robot is flat, and the front and rear ends are pointed; the front end of the fuselage 2 is provided with a flat-grain assembly, and the flat-grain assembly includes a flat-grain shovel 1, a support arm and a second driving device; One end of the arm is hinged on the fuselage 2, the other end is connected to the flat grain shovel 1, and the second driving device is connected to the support arm, which drives the flat grain shovel up and down by changing the angle between the support arm and the fuselage. Wherein the second driving device is connected to the control system, the second driving device includes a driving cylinder, the driving cylinder includes a cylinder seat and a piston rod, the cylinder seat is connected to the fuselage 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com