Preparation method of composite chemically-toughened glass, and toughening furnace system

A chemical tempering glass and tempering furnace technology, applied in the field of glass manufacturing, can solve the problems of manpower, time and resource waste, long salt washing process, etc., to achieve the effect of improving the tempering effect, prolonging the service life and improving the working efficiency of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

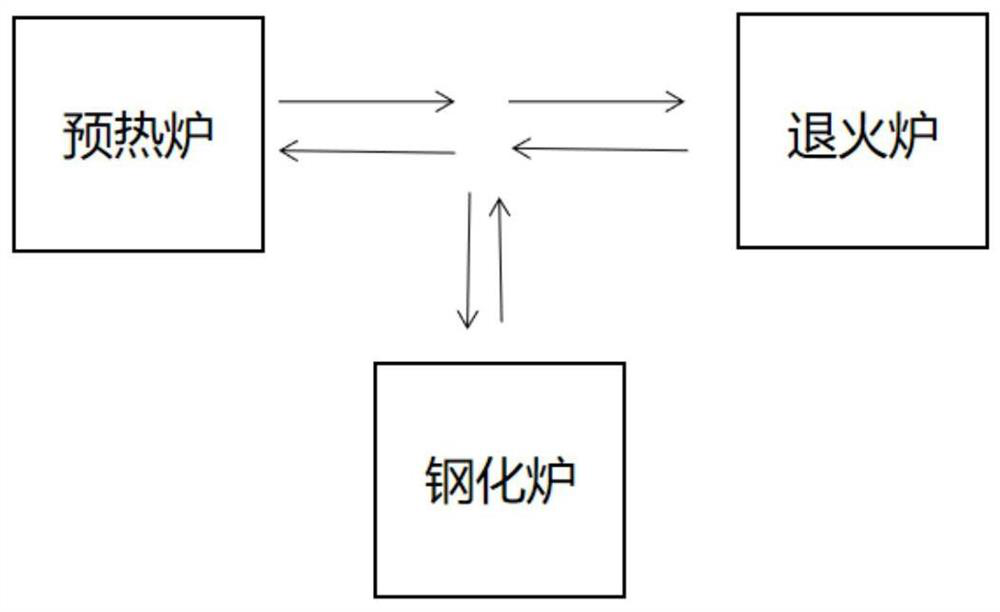

[0023] The invention provides a glass composite chemical tempering furnace system, which implements high-efficiency and fully automatic tempering of glass.

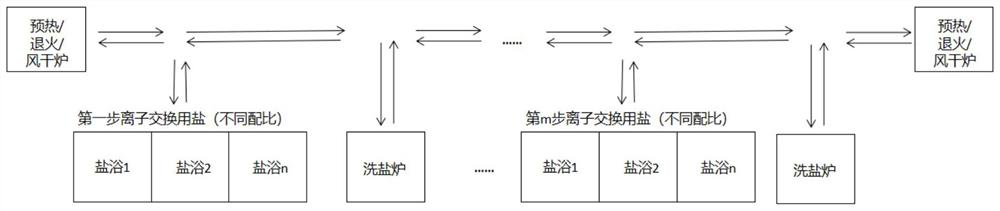

[0024] figure 2 It is a glass composite chemical tempering furnace system provided by the present invention, which includes two preheating / annealing / drying furnaces, multiple tempering furnaces for chemically tempering glass, salt washing furnace for cleaning glass, and the glass to be tempered / The cleaning glass is put into or taken out of the handling mechanism of each tempering furnace. Multiple tempering furnaces and salt washing furnaces are independently installed, and the preheating / annealing / drying furnace is set above the tempering furnace and salt washing furnace.

[0025] Among them, the preheating / annealing / drying furnace is a multi-purpose furnace, which can be used for pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap