Road culvert reinforcing system and construction method thereof

A culvert and road technology, which is applied to road culvert reinforcement system and its construction field, can solve the problems of large limitations and cannot be applied to the increase of road transport loads, and achieve the effect of small limitations and improved bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

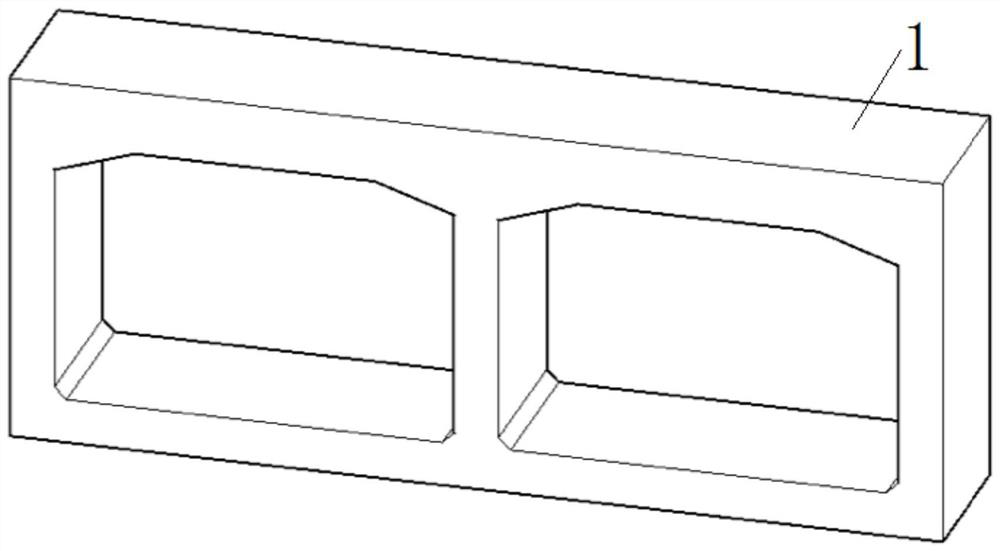

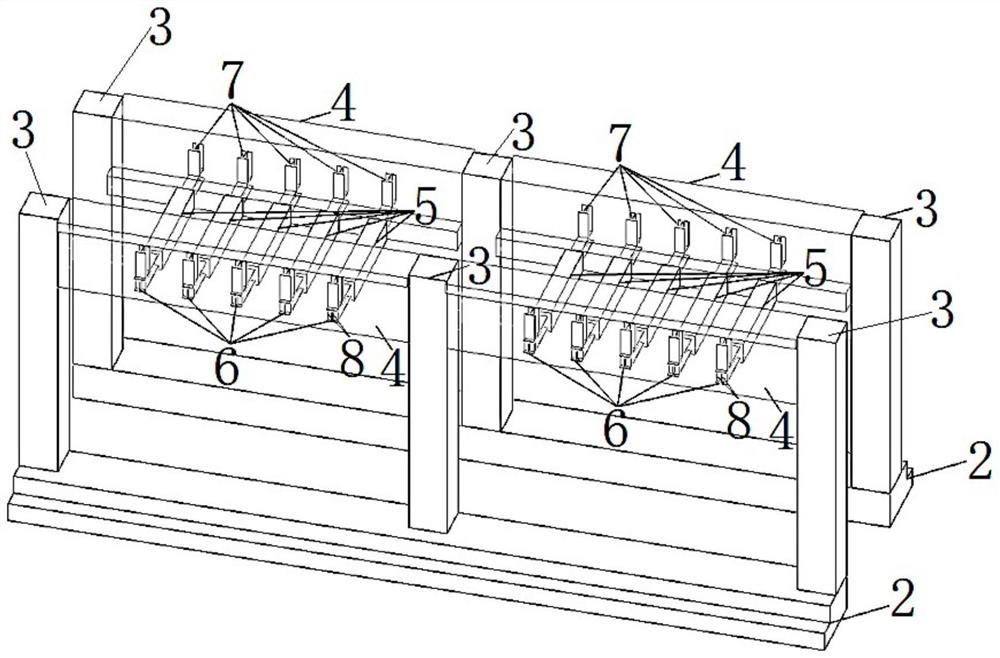

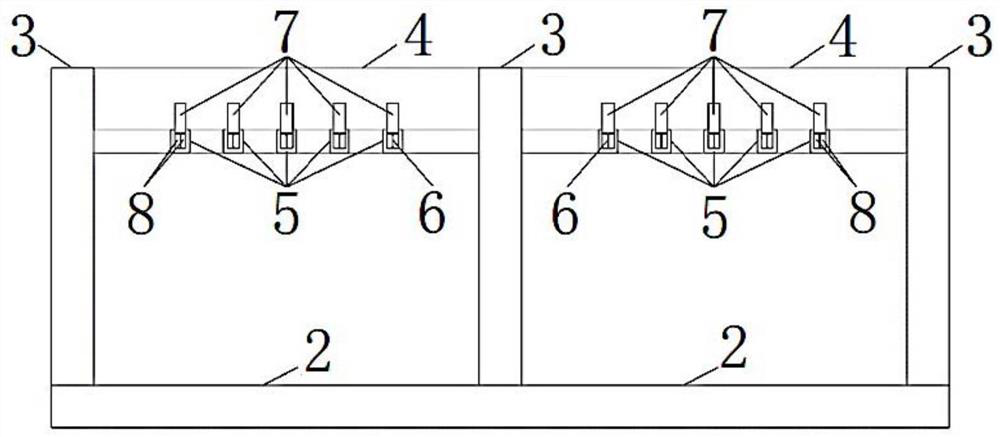

[0068] This embodiment takes an existing double-hole culvert as an example, as attached figure 1 As shown, the existing double-hole culvert includes a base, a roof and three vertical walls arranged between the base and the roof; in this embodiment, the direction of passage of the existing double-hole culvert is the length direction, and One end is the front end, and the other end is the rear end; the width direction is perpendicular to its passing direction; if attached Figure 2-13 As shown, this embodiment provides a road culvert reinforcement system, which includes two reinforcement units, a number of transverse structural beams 5 , a number of shaped steel beams 6 , a number of shaped steel columns 7 and a number of stiffeners 8 .

[0069] The two reinforcement units have the same structure and are symmetrically arranged at the front and rear ends of the existing culvert 1; the reinforcement units include a strip foundation 2, three structural columns 3 and two longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com