Pulverized coal adding device of thermal power generation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

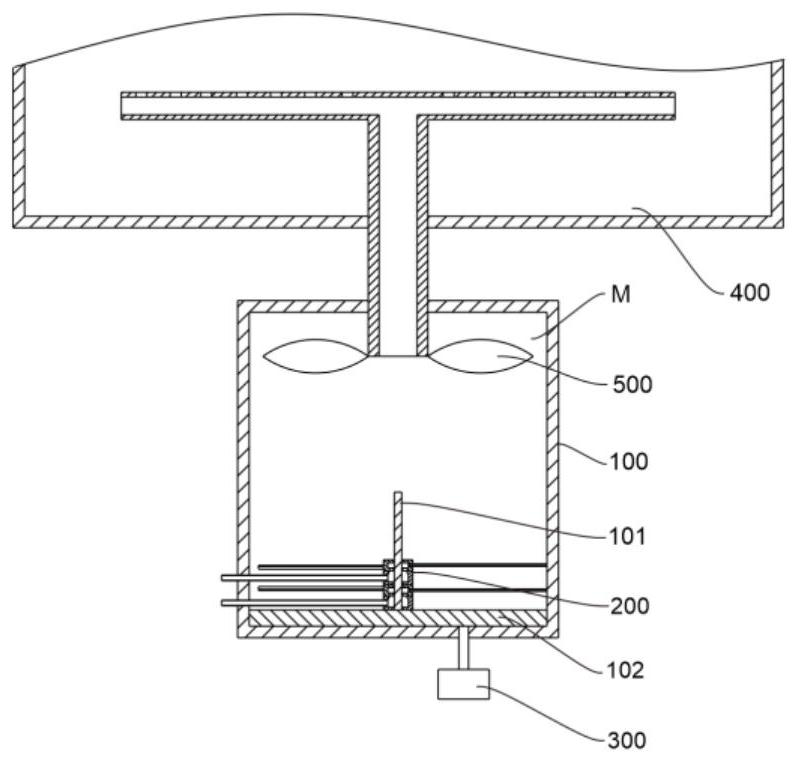

[0030] refer to figure 1 and figure 2 , is the first embodiment of the present invention, this embodiment provides a kind of pulverized coal addition device of thermal power generation equipment, the pulverized coal addition device of thermal power generation equipment comprises mixing chamber 100, addition unit 200, air compressor 300, furnace Body 400 and exhaust unit 500.

[0031] An accommodating space M is provided inside the mixing chamber 100 , and a column 101 is arranged in the accommodating space M, and the column 101 is coaxially arranged with the mixing chamber 100 .

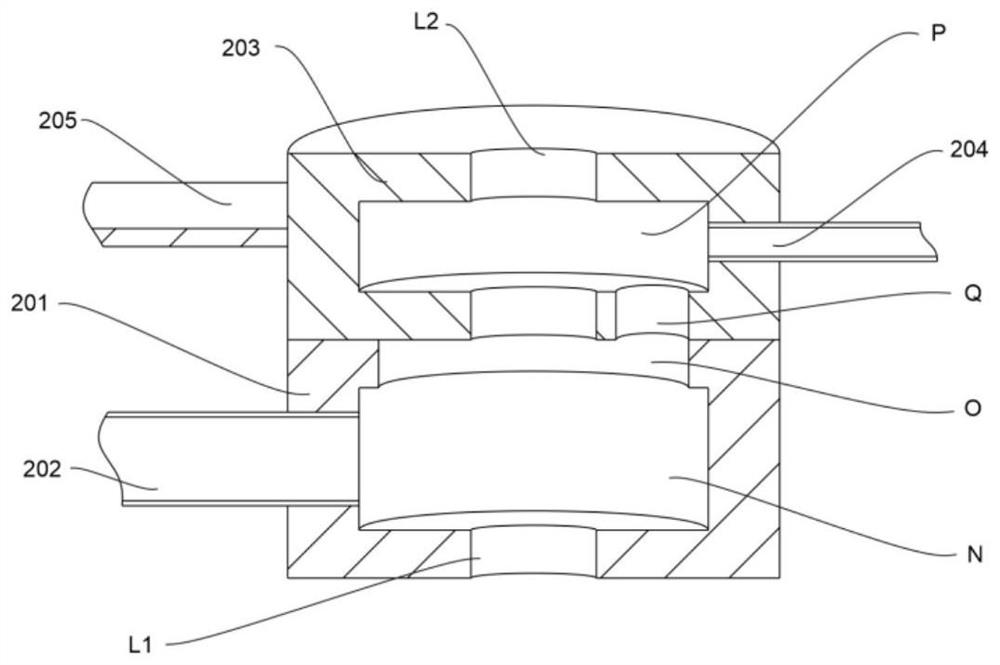

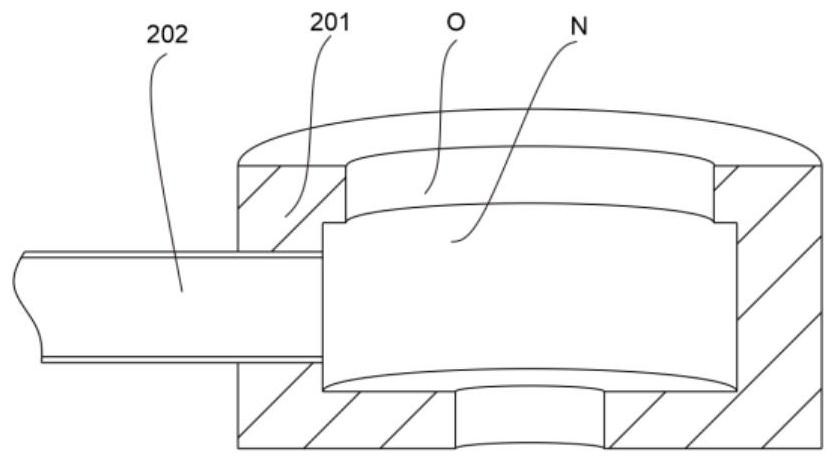

[0032] The adding unit 200 includes a mounting base 201, an air intake pipe 202, a rotating base 203 and an air outlet pipe 204, the mounting base 201 is installed on the column 101, the air intake pipe 202 communicates with the mounting base 201, and the rotating base 203 is rotationally connected with the mounting base 201, the outlet pipe 204 is connected with the rotating base 203, the mountin...

Embodiment 2

[0038] refer to Figure 1~6 , is the second embodiment of the present invention, which is different from the first embodiment.

[0039] Specifically, the exhaust unit 500 includes a connecting pipe 501, the connecting pipe 501 is arranged between the accommodating space M and the furnace body 400, one end is rotatably connected to the mixing chamber 100, and the other end is connected to the The furnace body 400 is rotatably connected.

[0040] Further, the exhaust unit 500 also includes a stirring fan 502, which is located in the accommodating space M and installed at one end of the connecting pipe 501; when the agitating fan 502 is working, the accommodating The wind in the space M rotates, and the rotating wind has the property of converging, that is, the gas is converging towards the middle position.

[0041] Preferably, the exhaust unit 500 also includes an exhaust pipe 503, the exhaust pipe 503 is installed at the other end of the connecting pipe 501, and is also provi...

Embodiment 3

[0044] refer to Figure 1-7 , is the third embodiment of the present invention, which is different from the first two embodiments:.

[0045] Specifically, the mixing chamber 100 also includes a diffuser plate 102, the diffuser plate 102 is installed at the bottom of the mixing chamber 100, and is also provided with a plurality of through holes 102a, a plurality of the through holes 102a It communicates with the output end of the air compressor 300; the air flow of the air compressor 300 is divided into multiple streams, which can disturb the air flow at the bottom of the mixing chamber 100, thereby allowing different additives to be quickly mixed.

[0046] Further, at least one through hole 102a is provided on any radius of the diffuser plate 102; this can ensure that no matter where the inclined plate 205 is in the mixing chamber 100, the air blown out from the air compressor 300 All the gas can act on the inclined plate 205, thereby ensuring that the rotating base 203 can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com