Rigid-flex composite explosion-proof tank

A rigid-flex composite, explosion-proof tank technology, used in blasting, synthetic resin layered products, coatings, etc., can solve the problems of difficult opening of the top cover, easy locking, secondary damage, etc., to enhance the explosion-proof performance, avoid Structural Fragmentation, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with specific embodiments.

[0055] This embodiment provides a rigid-flexible composite explosion-proof tank, which has the characteristics of strong explosion-proof capability and high safety factor.

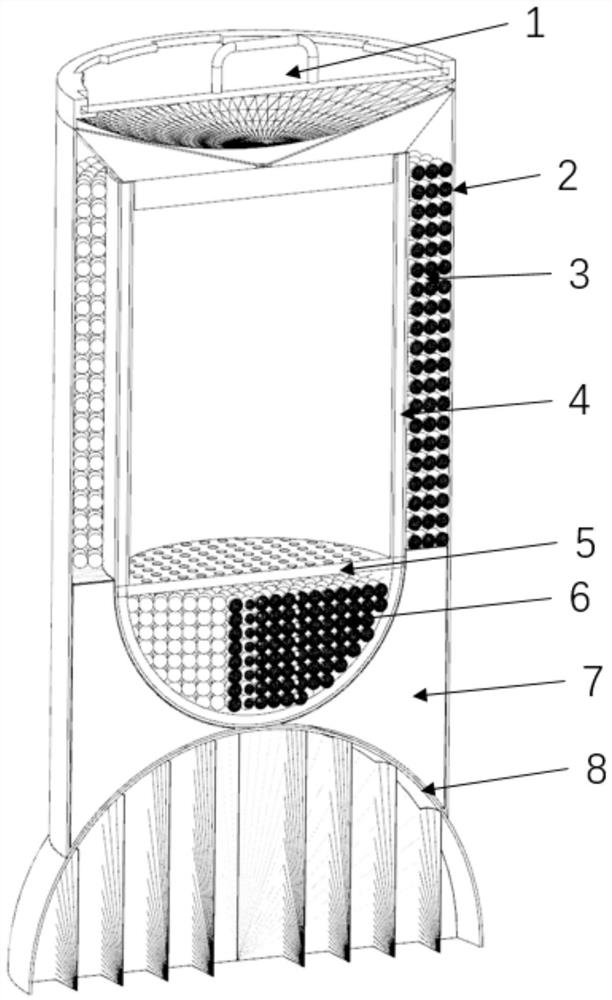

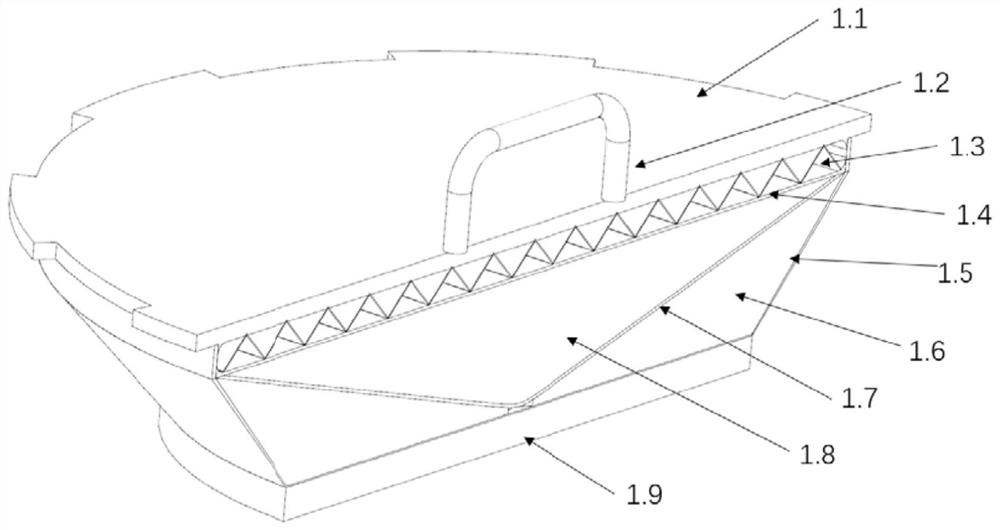

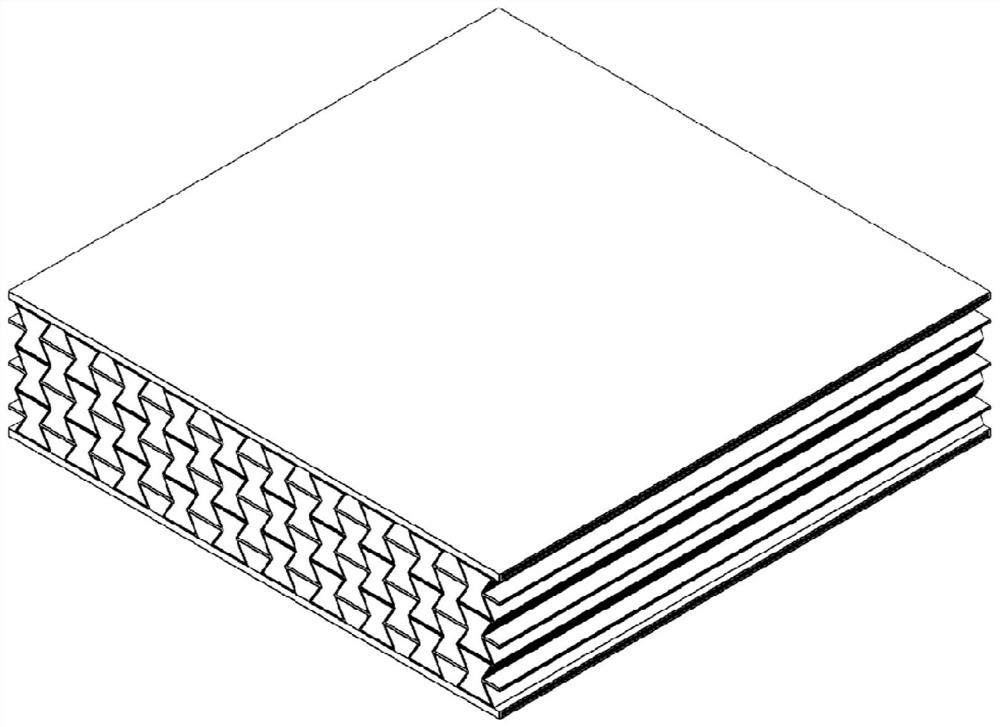

[0056] Such as figure 1As shown, the rigid-flexible composite explosion-proof tank includes: a top cover 1 , an outer shell 2 , an interlayer filler 3 , an inner shell 4 , a bottom energy-absorbing layer 5 , a bottom filler 6 , a bottom buffer layer 7 and a bottom support 8 .

[0057] Wherein the outer casing 2 is a cylindrical structure with openings at both ends, the inner casing 4 is a top opening, and the bottom is a cylindrical structure closed by a hemispherical casing (that is, the inner casing 4 includes a cylindrical section and a hemispherical section); the inner casing The bottom of the body 4 is connected to the hemispherical bottom support 8 through the bottom buffer layer 7, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com