Transformer oil intelligent temperature adjusting system and transformer oil intelligent temperature adjusting method

A technology of transformer oil and intelligent temperature regulation, applied in the field of transformers, can solve problems such as potential danger and insulation failure, and achieve the effect of ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

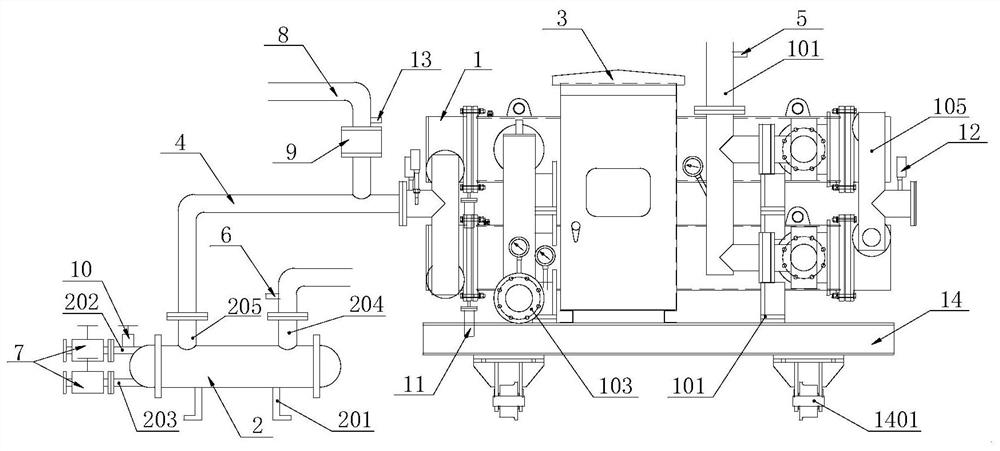

[0018] In this embodiment, the oil-water cooler 1 has a double-pipe structure.

[0019] In this embodiment, the steam inlet pipeline 202 is provided with a pressure relief valve 10 , and the pressure relief valve 10 is located between the steam inlet and the electric valve A 7 . The pressure relief valve 10 plays a role of releasing pressure on the pipeline and the steam heater 2 to avoid blockage, thereby improving the use safety of the steam heater 2 . The closing time of the pressure relief valve 10 can be designed as required, and can be controlled by a time relay.

[0020] In this embodiment, the oil-water cooler 1 is provided with a leakage alarm 11 . Once water leakage or oil leakage occurs, oil or water will flow into the leakage alarm 11 to trigger an alarm, so that technicians can find out and solve it in time, thereby preventing oil or water from leaking into the transformer. Further, the leakage alarm 11 is a liquid level alarm, that is, the leakage alarm 11 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com