Air-cooled fuel cell stack

A fuel cell stack, air-cooled technology, applied to fuel cells, circuits, electrical components, etc., to achieve high output voltage, cost reduction, and low output current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

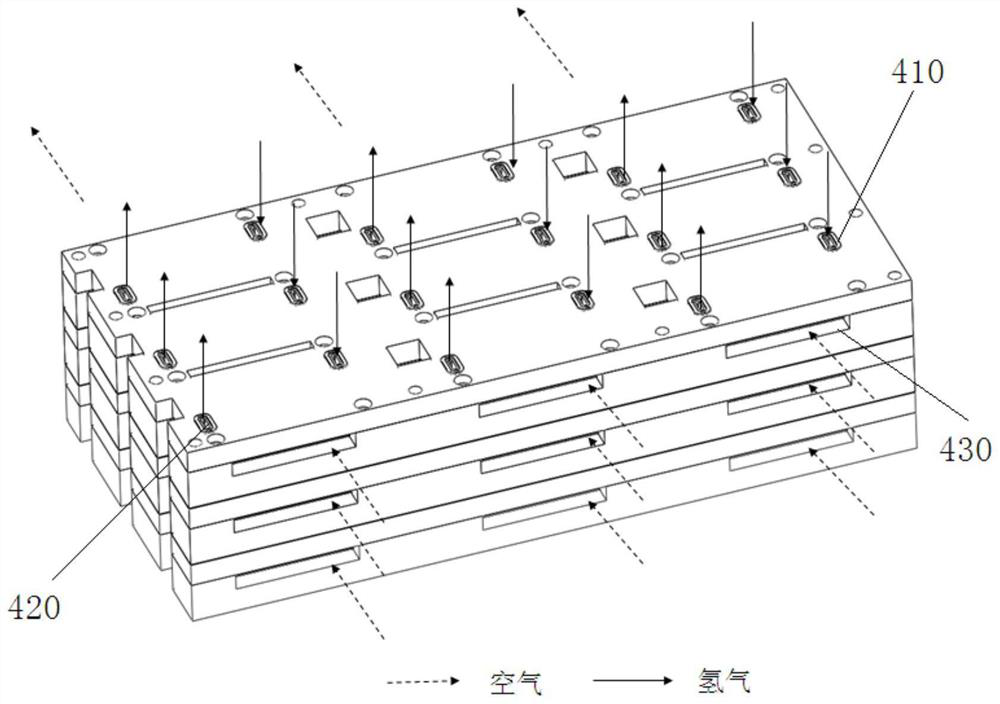

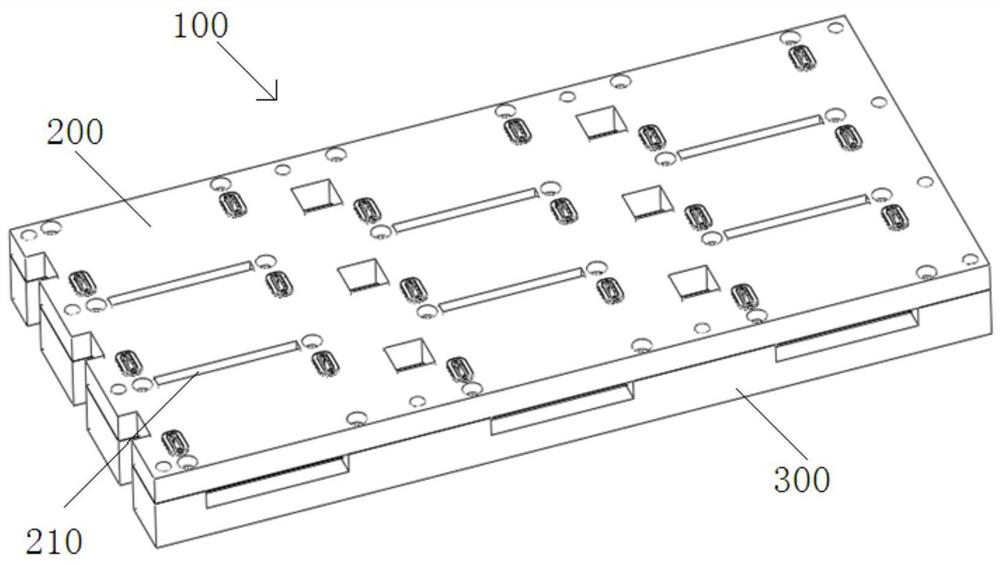

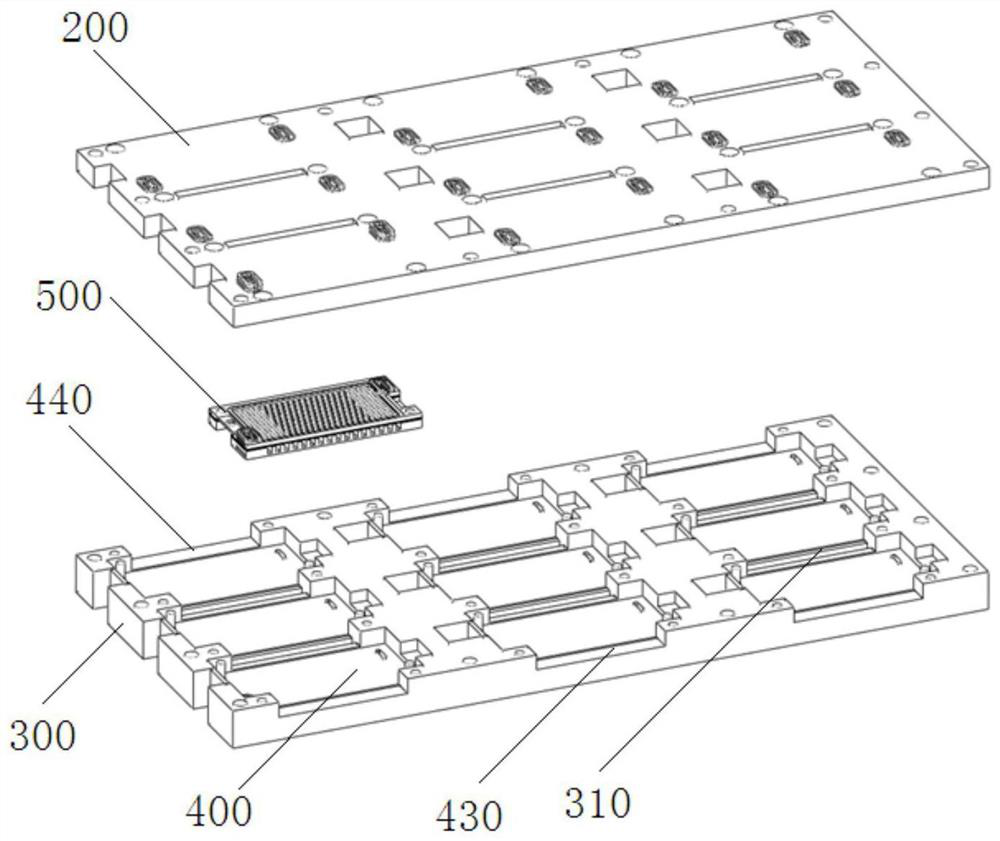

[0044] Such as Figure 1-5 As shown, three stacked and assembled modules 100 form an electric stack. In order to prevent the loss of electric energy and prevent the occurrence of electric shock accidents, it is necessary for the upper pressing plate 200 and the lower pressing plate 300 that are in direct contact with the external environment to be made of insulating materials; Each module 100 includes a lower pressure plate 300 and an upper pressure plate 200 made of insulating materials, and there are nine accommodation cavities 400 for accommodating fuel cell cells 500 between the lower pressure plate 300 and the upper pressure plate 200, and the nine accommodation cavities 400 form 3×3 arrangement. Each module 100 is equipped with multiple fuel cell cells 500, which can further reduce the cost and reduce the difficulty of stack assembly.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com