Novel axial coreless motor rotor structure and heat dissipation method thereof

A motor rotor and iron-free technology, which is applied in the direction of magnetic circuit shape/style/structure, electromechanical devices, electrical components, etc., can solve the problem of increased air gap magnetic flux density waveform distortion rate, motor back electromotive force waveform distortion rate increase, Problems such as deterioration of motor output power quality, etc., to achieve the effects of reducing harmonic content, reducing waveform distortion rate, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

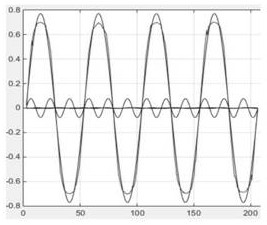

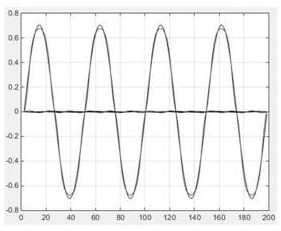

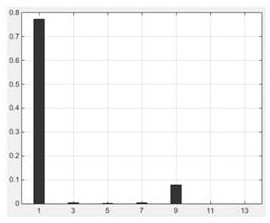

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0024] The invention discloses a novel axial iron-coreless motor rotor structure, which includes several permanent magnets 2 annularly distributed in the radial direction on the back iron 1, and there is an air gap between two adjacent permanent magnets 2, each adjacent U-shaped iron poles 3 are inserted into the air gap between the two permanent magnets 2 , and the air slots 4 formed by the U-shaped parts of all the U-shaped iron poles 3 face the back iron 1 .

[0025] Further, the axial height of the U-shaped iron pole 3 is equal to the thickness of the permanent magnet 2 , and the radial length of the U-shaped iron pole 3 is equal to the radial length of the perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com