Preparation method of soft capsule

A soft capsule and glue technology, which is applied in the directions of capsule delivery, medical preparations with non-active ingredients, and pharmaceutical formulations, can solve problems such as leakage of soft capsules, and achieve the effect of reducing the leakage rate and improving the anti-leakage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the soft capsule provided in the embodiment of the present application includes: S101-preparation of the mixture glue and S102-compression molding of the soft capsule.

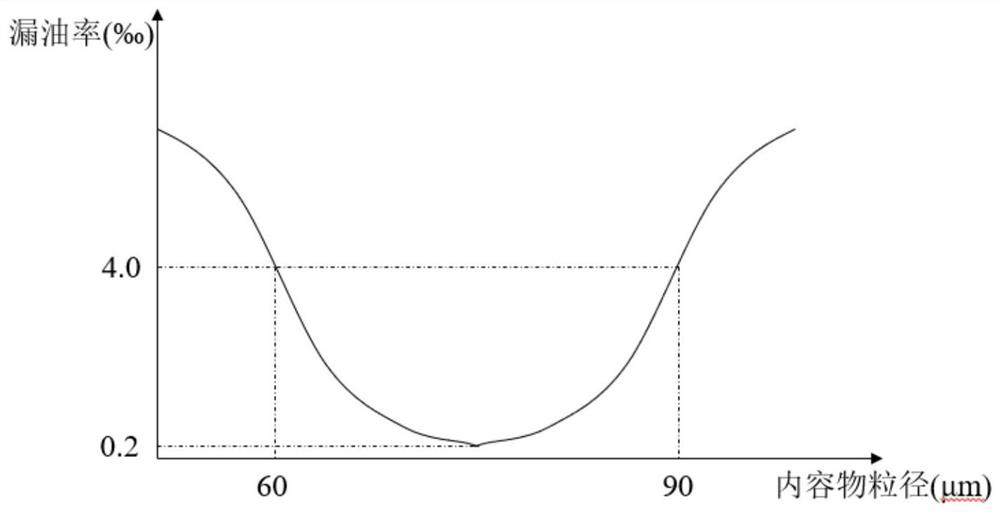

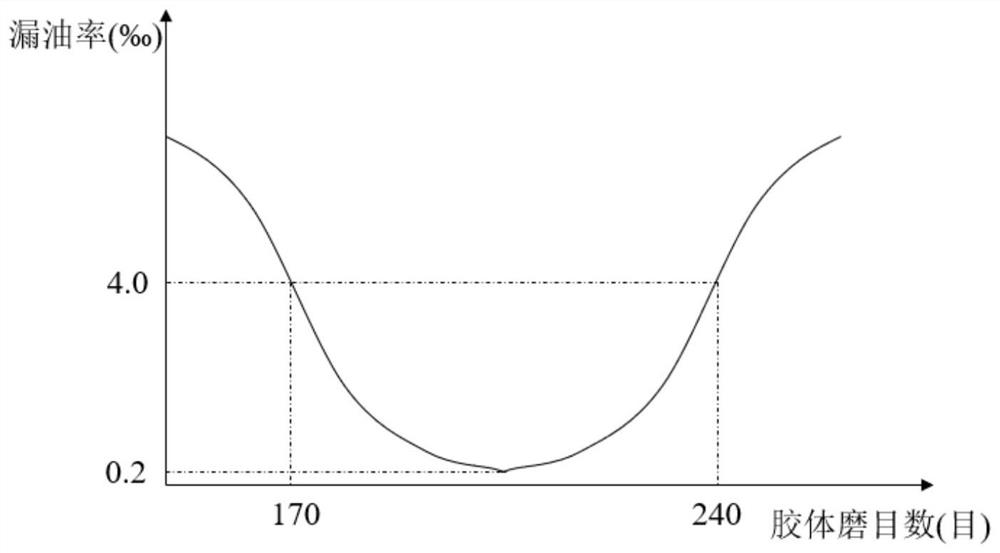

[0038] S101-The preparation of the mixture glue includes the preparation of capsule material glue and the preparation of the content medicine solution, the preparation of the content medicine solution includes establishing the particle size control of the content medicine solution, and establishing the control of the colloid used for the preparation of soft capsules Grinding mesh control. The establishment of the particle size control of the content medicinal liquid and the control of the colloid mill mesh number used to prepare the soft capsule, wherein the establishment of the particle size control of the content medicinal liquid includes: controlling the content of the The particle size of the liquid medicine is 60-90 μm; the establishment of the control of the mesh number o...

Embodiment 1

[0057] The preparation method of a soft capsule provided in Example 1 includes S101-preparation of the mixture glue and S102-compression molding of the soft capsule.

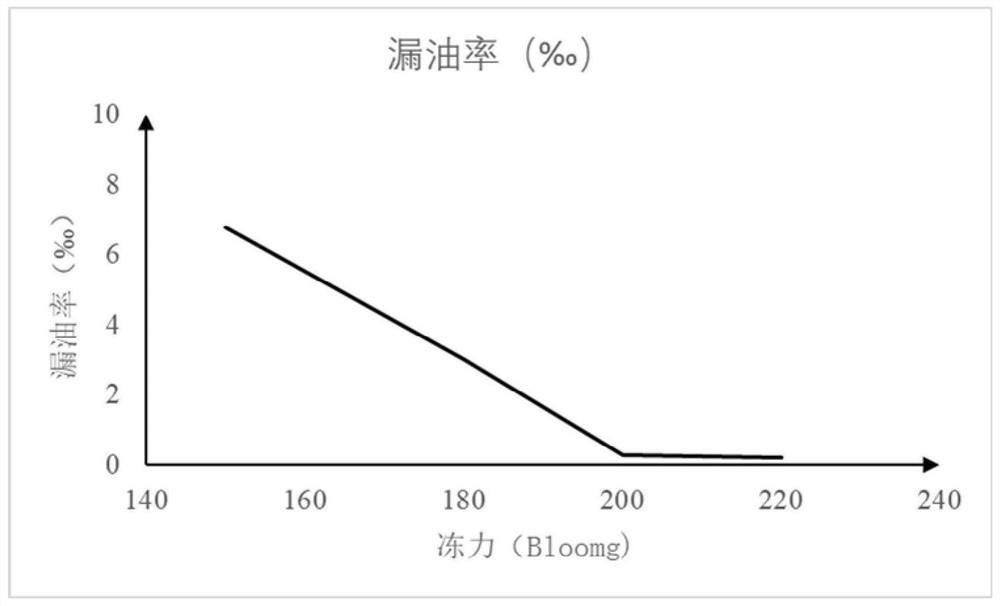

[0058] S101-Preparation of the mixture glue includes capsule material glue preparation and content drug solution preparation. The preparation of the capsule material glue specifically includes: putting gelatin (freezing power of 180 Bloomg), glycerin and water into the glue tank according to the mass ratio of 1:0.3:1.2, stirring and heating to melt the gel material Afterwards, keep warm for 1-2 hours, let it stand until the foam rises, and then keep warm and filter to get the capsule material glue (freezing force is 160B Loomg), which is ready for use. The preparation of the content medicinal solution specifically includes: placing the content raw material of the soft capsule and an appropriate amount of water in a colloid mill and grinding for 10-30 minutes, so that the content raw material forms a medicinal li...

Embodiment 2

[0061] The preparation method of a soft capsule provided in Example 1 includes S101-preparation of capsule material glue and S102-compression molding of soft capsule.

[0062] S101-Preparation of the mixture glue includes capsule material glue preparation and content drug solution preparation. The preparation of the capsule material glue specifically includes: putting gelatin (freezing power of 150 Bloomg), glycerin, water and other components into the glue tank according to the mass ratio of 1:0.3:1.2, stirring and heating to melt the gel material Afterwards, keep warm for 1-2 hours, let it stand until the foam rises, and then keep warm and filter to obtain the capsule material glue (freezing force is 120B Loomg), which is ready for use. The preparation of the content medicinal solution specifically includes: placing the content raw materials of the soft capsule and an appropriate amount of water in a colloid mill to grind for 10-30 minutes, so that the content raw materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com