Homogenizing mechanism for preparing ointment smeared on skin

A technology for ointment and skin, which is applied in the field of homogenization mechanism for the preparation of ointment based on skin application, can solve the problems of poor effect, inability to vibrate and homogenize, and achieve the effect of improving heat dissipation and improving homogenization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

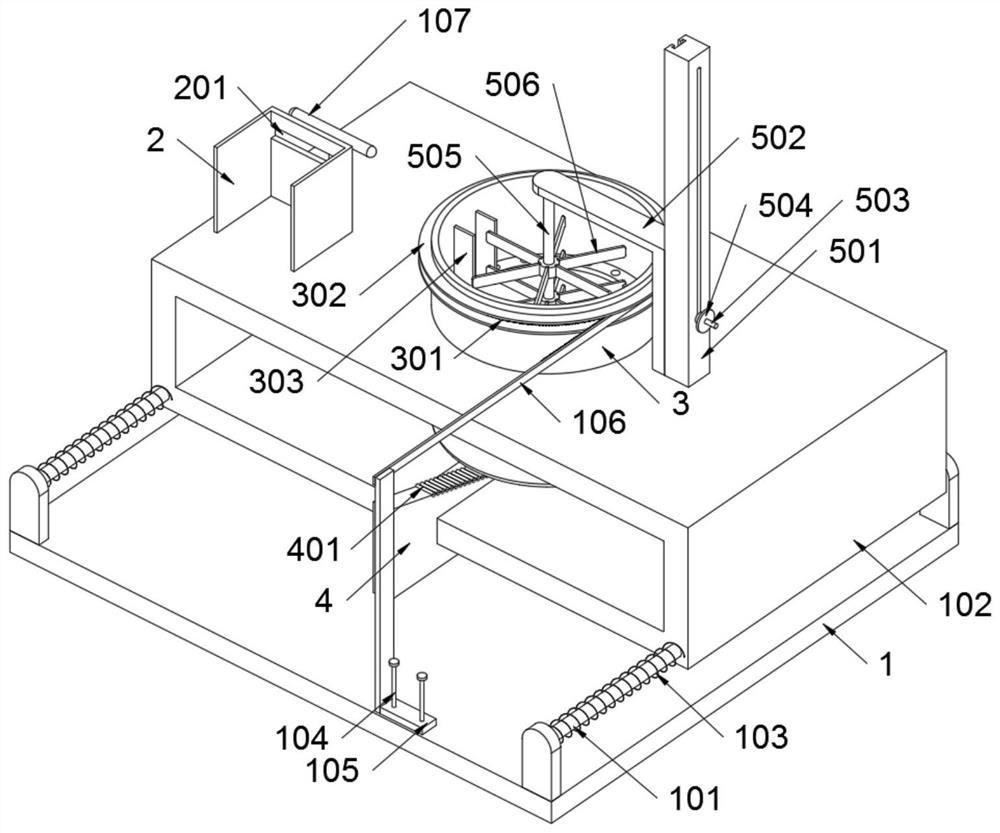

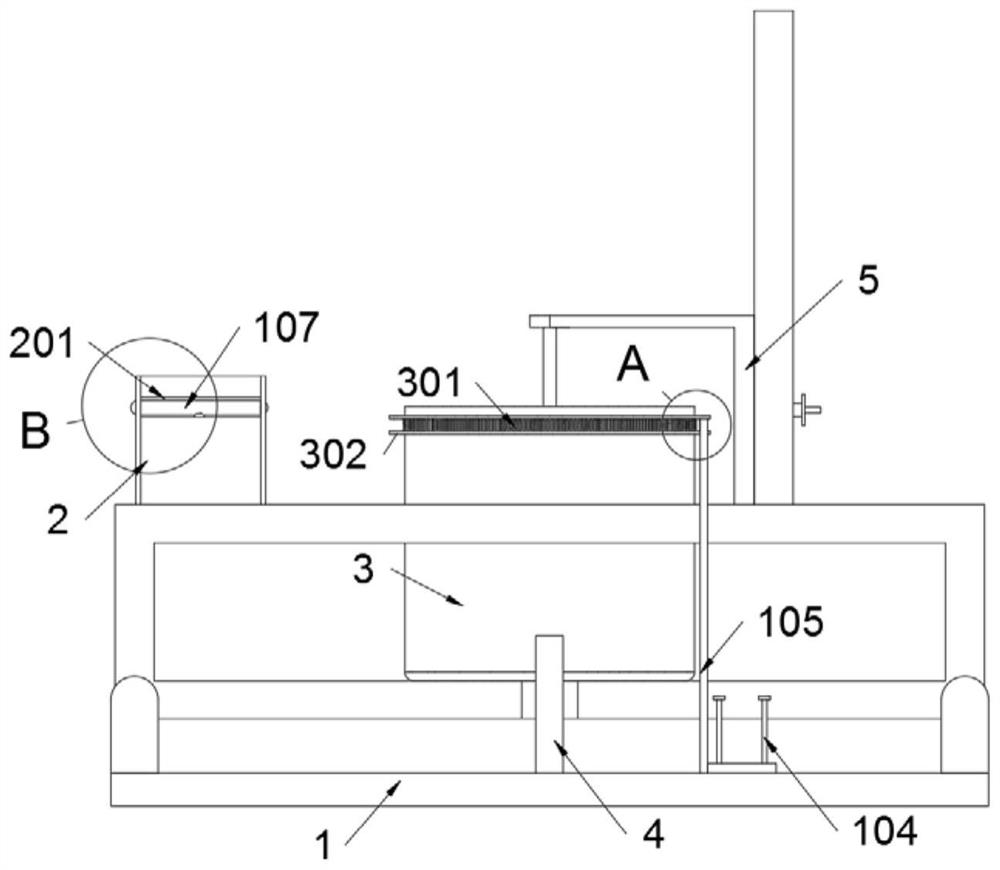

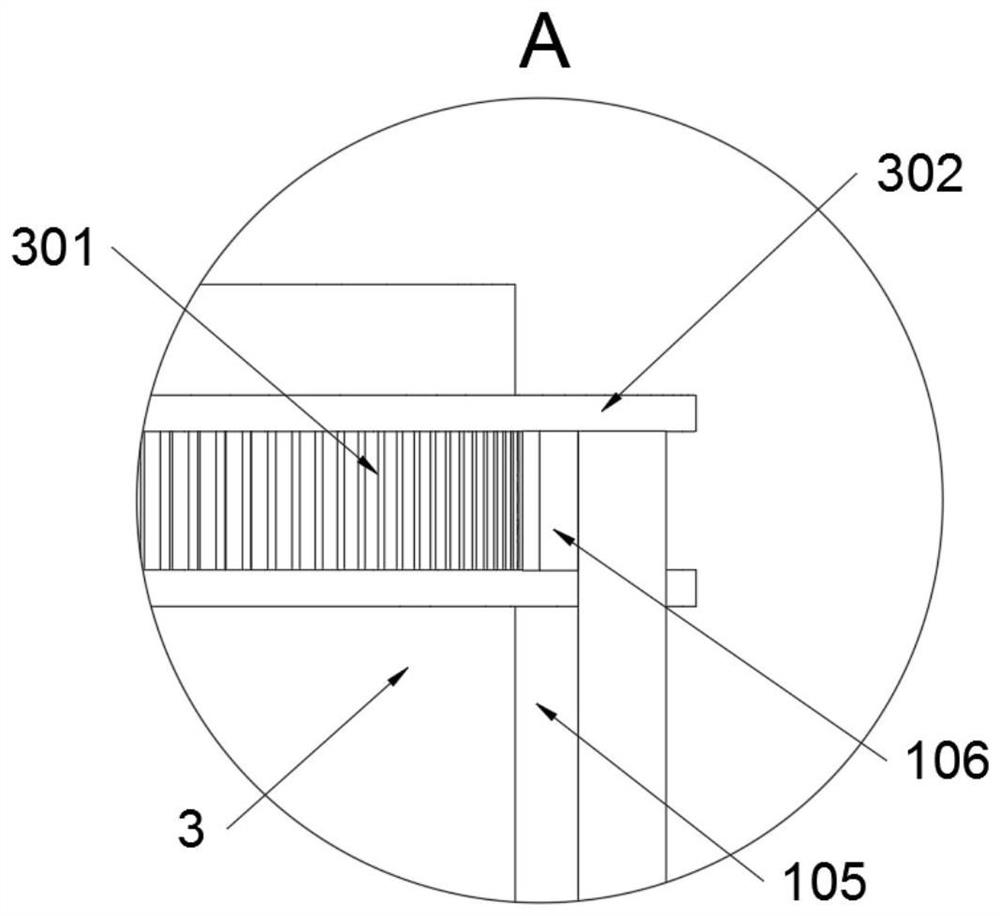

[0037] as attached figure 1 to attach Figure 8 Shown:

[0038] The invention provides a homogeneous mechanism for preparing ointment based on skin smearing, comprising a base 1; An auxiliary block 4 is welded, and a mixing part 5 is installed on the base 1 .

[0039] Reference as figure 1 , the base 1 includes: sliding rods A101, two sliding rods A101 are provided, and the two sliding rods A101 are symmetrically welded on the base 1; the two sliding rods A101 are slidably connected with a placement seat 102, and the placement seat 102 is placed There is a barrel body 3; elastic parts 103, two elastic parts 103 are provided in total, and the two elastic parts 103 are respectively sleeved on the two sliding rods A101, and the two elastic parts 103 together form the elastic reset of the placement seat 102 structure.

[0040] Reference as Figure 5 and Figure 6 , the auxiliary block 4 is an inclined plate structure; the auxiliary block 4 of the present application is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com