Dynamic layering and filtering device for terrestrial organic matters and implementation method thereof

The technology of a filtering device and a layering device is applied in the field of dynamic layered filtering device for land-sourced organic matter, which can solve the problems of difficulty in ensuring the layering and filtration of gas organic matter and liquid organic matter, difficulty in ensuring the filtering feeling of harmful gases, affecting exhaust efficiency, and the like. To avoid unclean filtering, improve filtering effect, and ensure the effect of layering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

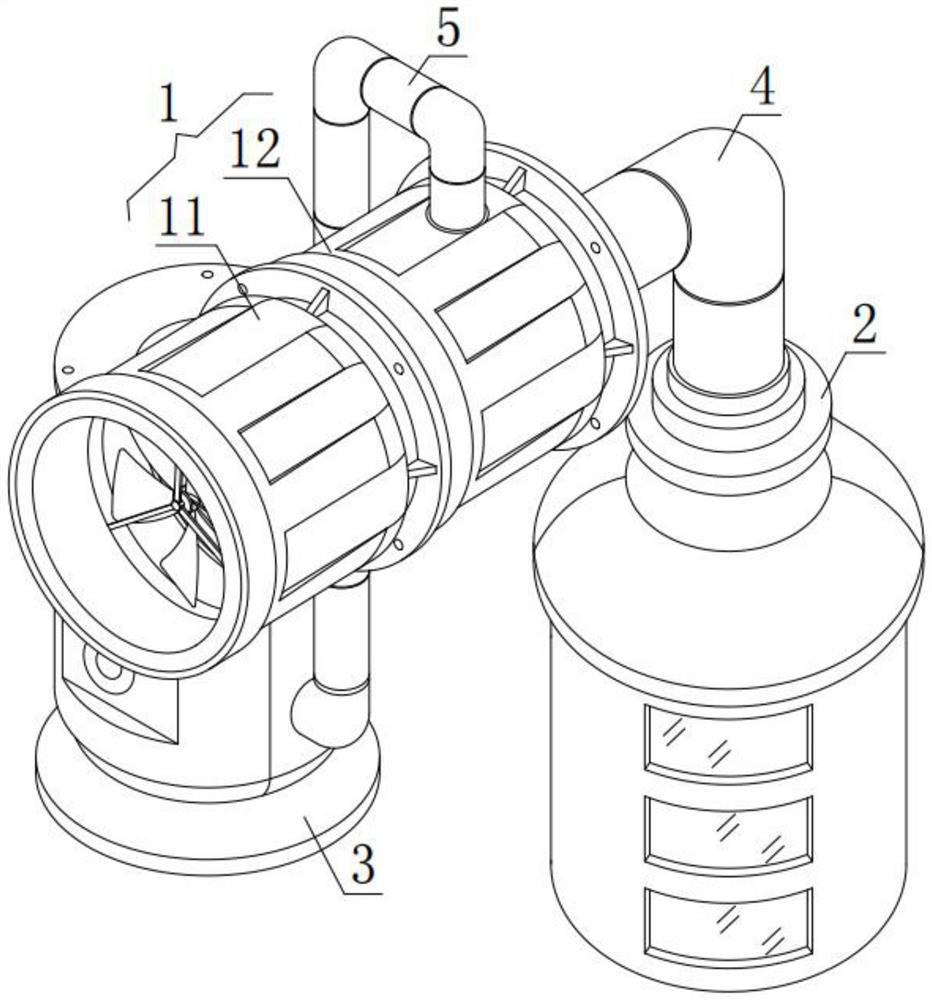

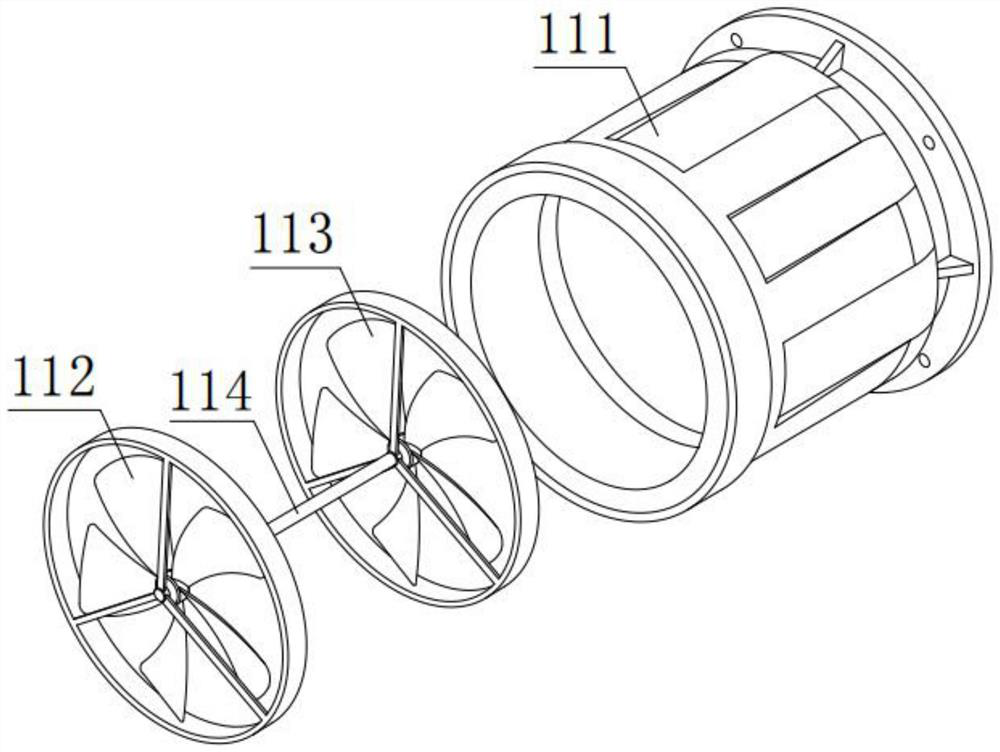

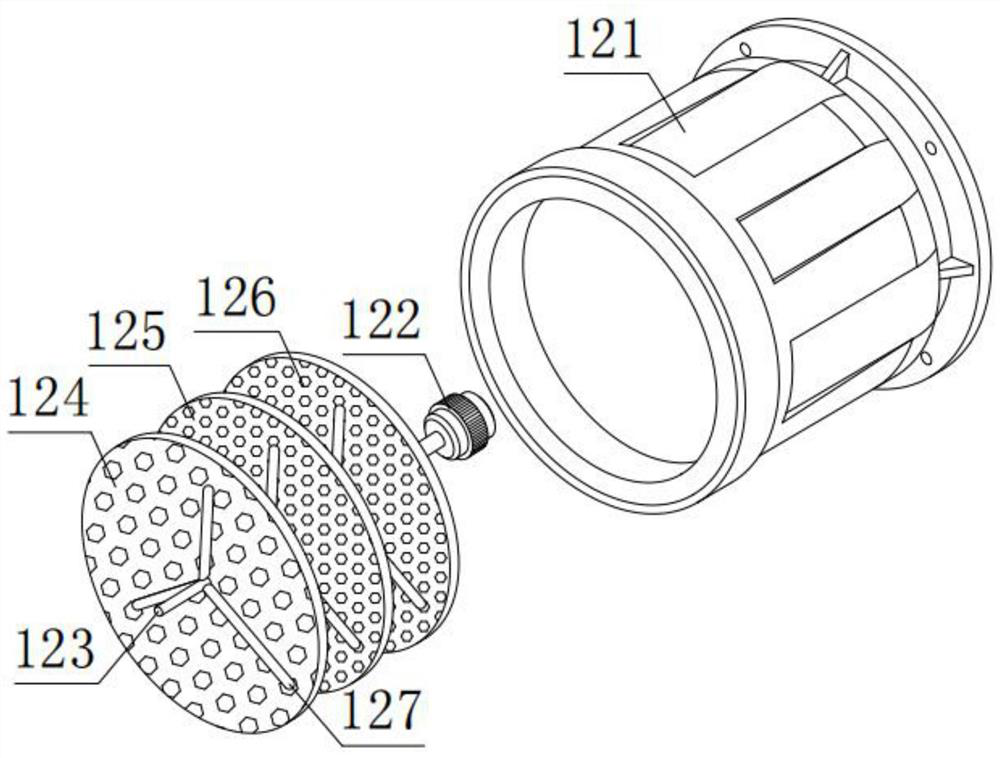

[0036] see Figure 1-3 , a dynamic layered filtration device for land-source organic matter, comprising a collection and separation device 1, a liquid organic matter layering device 2 and a gas filtration and purification device 3, the lower end of one side of the collection and separation device 1 is fixed to the upper end of the liquid organic matter layering device 2 through an outlet pipe 4 Connection, the upper end of one side of the collection and separation device 1 is fixedly connected with the lower end of one side of the gas filtration and purification device 3 through the outlet pipe 5, the collection and separation device 1 is composed of a collection mechanism 11 and a gas-liquid separation mechanism 12, and the collection mechanism 11 is connected with the gas-liquid separation mechanism through bolts 12 are fixedly connected, and the collection mechanism 11 includes a collection pipe 111, a first fan 112, a second fan 113 and a transmission rod 114, and one end o...

Embodiment approach

[0039] The present invention provides another technical solution, a method for implementing a dynamic layered filtration device for terrestrial organic matter, comprising the following steps:

[0040] Step 1: The land-source organic matter enters the gas-liquid separation mechanism 12 through the collection mechanism 11, and the land-source organic matter is roughly filtered through the first filter disc 124, the second filter disc 125, and the third filter disc 126, and the liquid organic matter in the land-source organic matter passes through The water outlet pipe 4 flows into the liquid organic matter layering device 2, and the gaseous organic matter flows into the gas filtration and purification device 3 through the air outlet pipe 5;

[0041] Step 2: The liquid organic matter flows into the first tank body 21 evenly along the inner wall of the first upper cover 22 through the diversion funnel 241, and the first layered plate 251 filters the liquid with high density in the ...

Embodiment 2

[0044] see Figure 8 , different from Embodiment 1, a condensation plate 316, a defogging plate 312 and a filtrate box 317 are respectively installed in the second tank body 31, a filtrate 314 is housed in the filtrate box 317, and a heating wire for heating the filtrate 314 is arranged at the lower end of the filtrate box 317 318, one side of the filtrate box 317 is provided with an air inlet 315 connected to the air inlet 35, a condensing plate 316 is installed on the upper end of the filtrate box 317, and a defogging plate 312 is installed on the upper end of the condensing plate 316. Harmful substances in the air are chemically reacted and filtered at the same time, and the clean gas is filtered out to prevent the filter element 311 from being filtered cleanly and the discharged gas pollutes the environment. Heating at 318 improves the reaction between the gaseous organic matter and the filtrate 314, further improving the filtering effect.

[0045] The present invention p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com