Production mixing equipment for fermentation of probiotic dairy products

A technology for mixing equipment and dairy products, applied in dairy products, mixers, milk preparations, etc., can solve the problems of loss of adsorption force, low mixing efficiency, etc., to improve the mixing rate, increase the efficiency of production mixing, and reduce shock absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

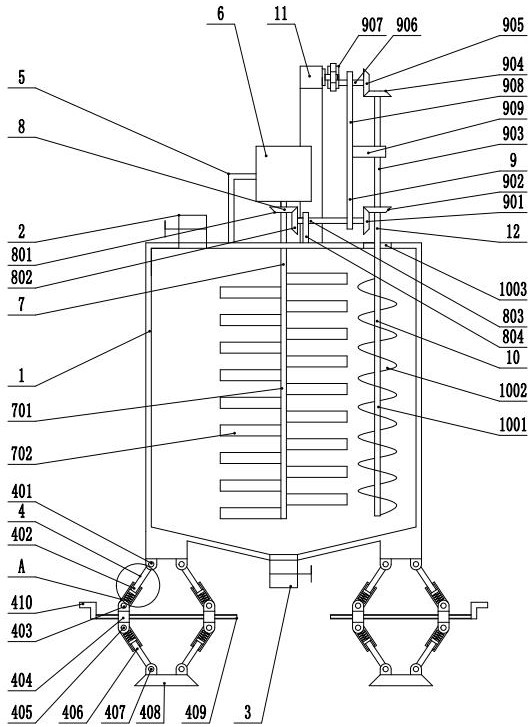

[0027] see Figure 1-3 , production and mixing equipment for fermenting probiotic dairy products, including a box body 1 and a feed port 2 and a discharge port 3 fixed on the case body 1;

[0028] The bottom of the box body 1 is fixedly connected to the supporting damping mechanism 4;

[0029] The box body 1 is fixedly connected to the first motor bracket 5;

[0030] The first motor bracket 5 is fixedly connected to the first motor 6;

[0031] The output shaft of the first motor 6 is fixedly connected to the first mixing mechanism 7;

[0032] The first mixing mechanism 7 is fixedly connected to the auxiliary mixing assembly 12, and the auxiliary mixing assembly 12 includes a transmission mechanism 8, a shaking frame mechanism 9, a second mixing mechanism 10 and an adjustment link mechanism 11, and the transmission mechanism 8 is used to drive the shaking frame mechanism 9 When working, the shaking frame mechanism 9 is used to drive the second mixing mechanism 10 to rotate, ...

Embodiment 2

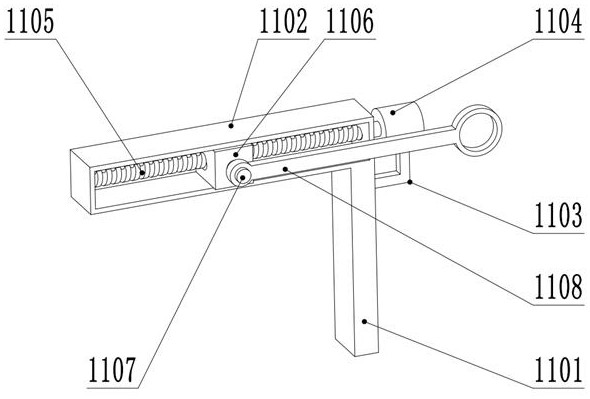

[0040] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the adjustment link mechanism 11 includes a mounting plate 1101 fixed on the box body 1, the mounting plate 1101 is fixedly connected to the adjustment frame 1102, and the mounting plate 1101 is fixed Connect the second motor bracket 1103, the second motor bracket 1103 is fixedly connected to the second motor 1104, the output shaft of the second motor 1104 is fixedly connected to the second threaded rod 1105, the second threaded rod 1105 is screwed to the adjustment block 1106, the adjustment block 1106 and the adjustment frame 1102 is slidingly connected, the adjustment block 1106 is rotatably connected to the adjustment shaft 1107, the adjustment shaft 1107 is fixedly connected to the connecting rod 1108, and the connecting rod 1108 is fixedly connected to the eccentric circle block 907. Specifically, when the second motor 1104 is turned on, the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com