Mural invisible protective layer sprayer with coating multi-filter refining device

A technology of protective layer and sprayer, which is applied in the field of mural invisible protective layer sprayer, which can solve the problems of low mixing efficiency, lower cost of sprayer, affecting the quality of wall hangings, etc., and achieve the effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Example: Please refer to Figure 1 to Figure 8 :

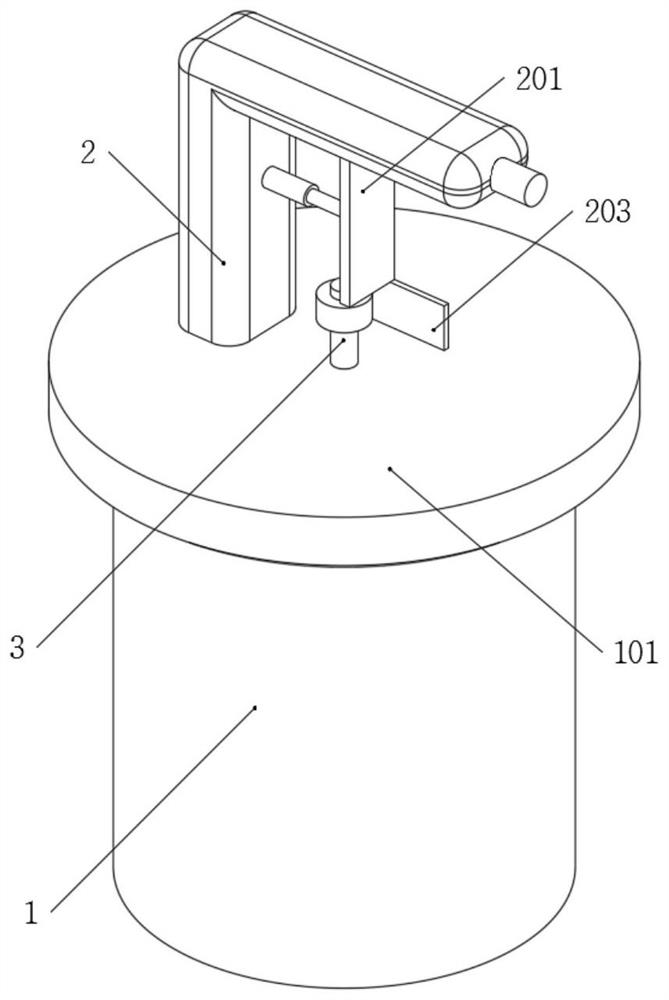

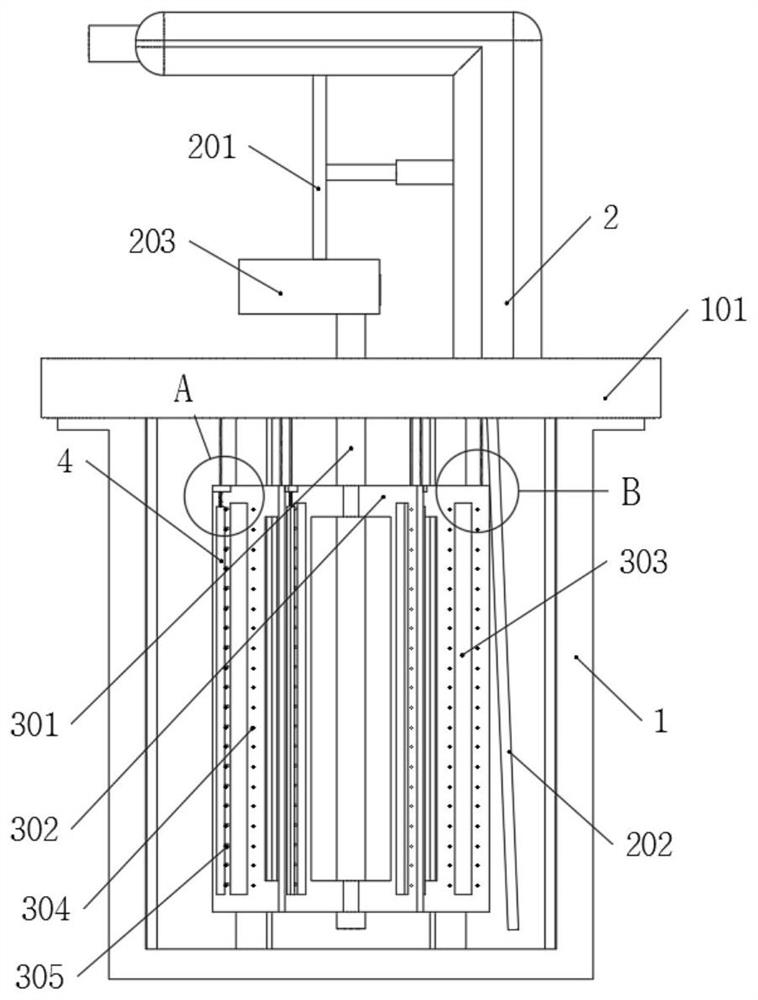

[0046] The present invention proposes an invisible protective layer sprayer for mural paintings with multi-filtering and fine-graining device for paint, comprising: a barrel body 1, a mixing part 3 and an auxiliary part 4;

[0047] The barrel body 1 is fixedly connected with a cover plate 101 by bolts, and a spray gun 2 is installed on the cover plate 101;

[0048] The mixing part 3 is composed of a rotating shaft 301, a blade plate 302, a magnet B303, a through hole A304, a through hole B305 and a gear 306, and the rotating shaft 301 is rotatably connected to the cover plate 101, and the rotating shaft 301 is welded with six blades in an annular array board 302;

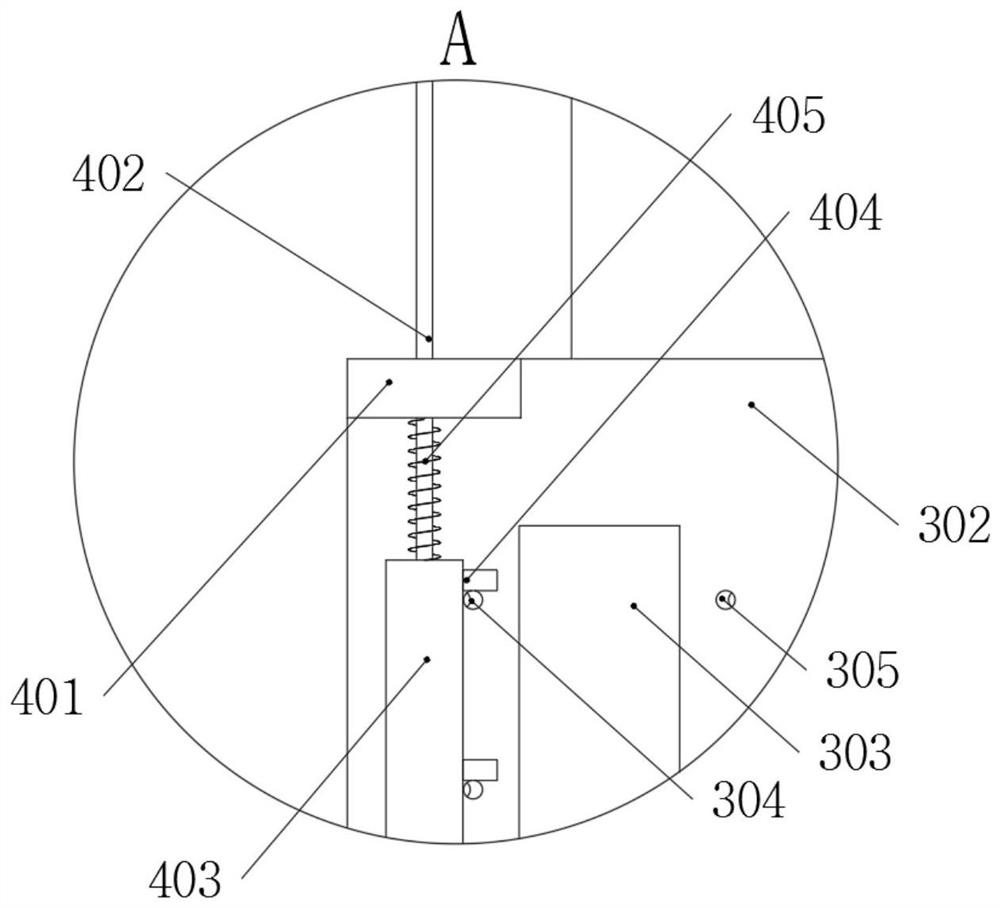

[0049] There are six auxiliary parts 4 in total, and the auxiliary parts 4 are composed of a sliding seat 401 , a sliding rod 402 , an auxiliary block 403 , a stopper 404 and an elastic member 405 , and the sliding seat 401 is welded on the blade plate 302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com