Bidirectional pressure balancing device and environmental test box

A balancing device and two-way pressure technology, applied in the field of environmental test chambers, can solve problems such as equipment compression deformation and equipment explosion, and achieve the effects of good stability, convenient assembly and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

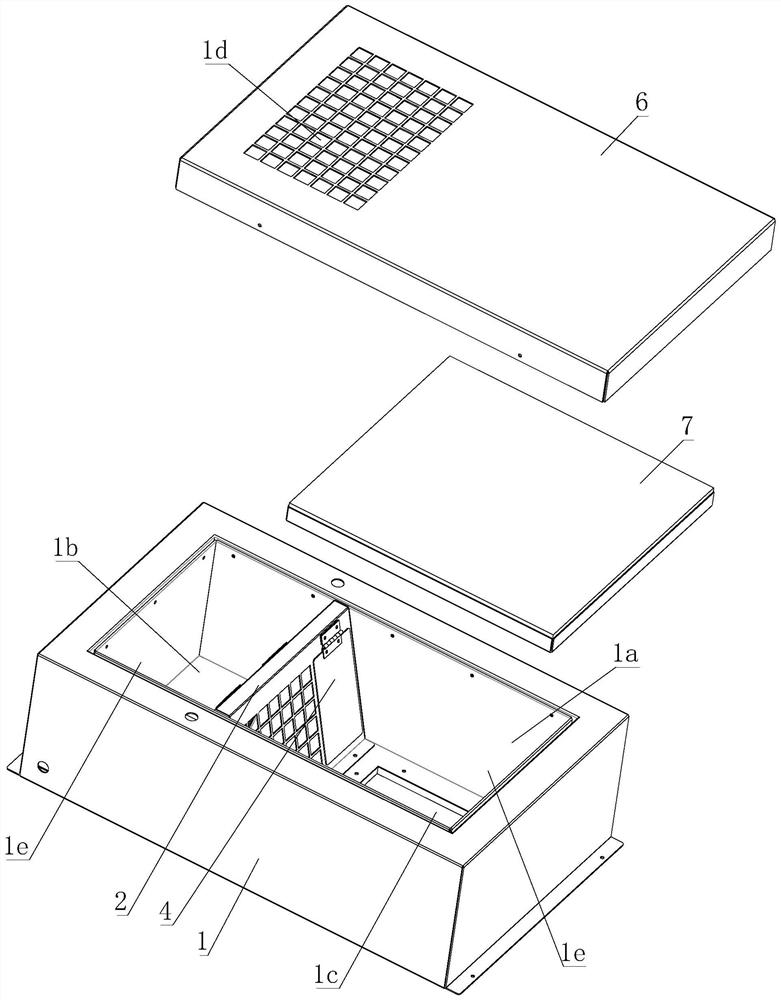

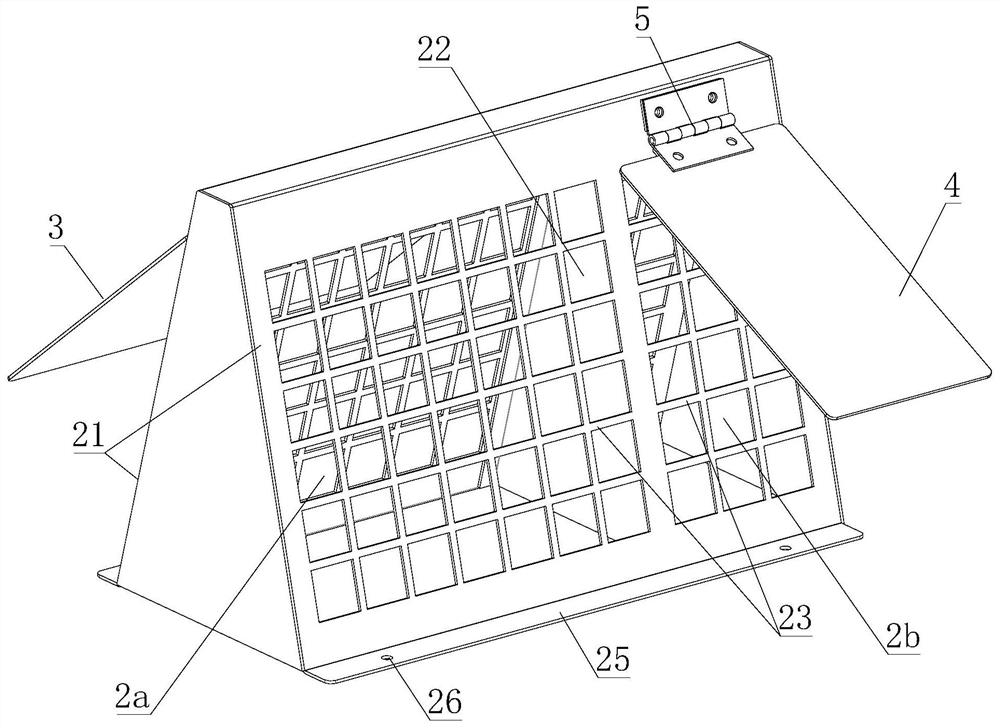

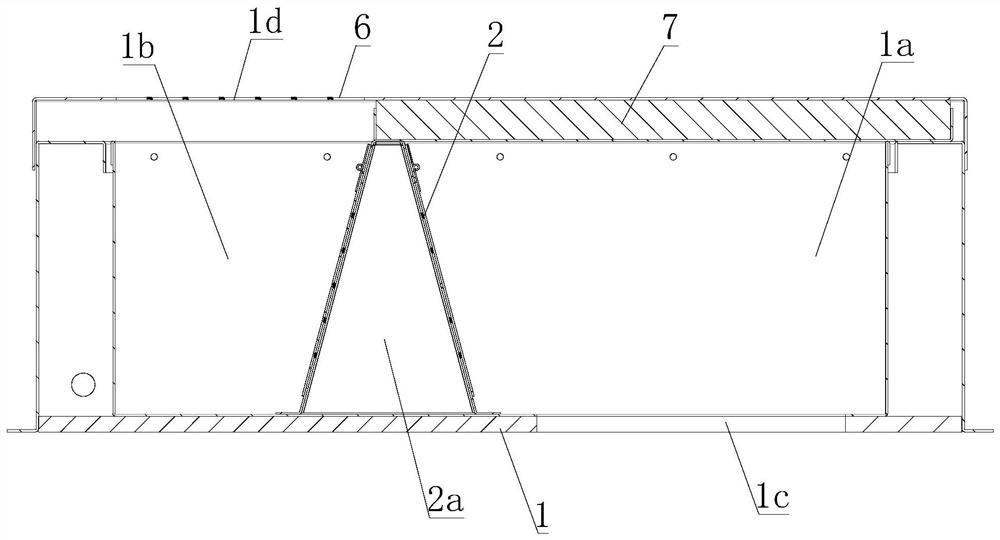

[0025] Such as Figures 1 to 3 As shown, a two-way pressure balance device, its structure includes a pressure relief box 1, the upper side of the pressure relief box 1 has an opening 1e, a cover plate 6 is installed on the opening 1e, and a partition member 2 is installed inside the pressure relief box 1 , the partition member 2 divides the internal space of the pressure relief box 1 into a first chamber 1a and a second chamber 1b, the bottom side of the first chamber 1a is provided with a first vent hole 1c, and the top side of the second chamber 1b It is a cover plate 6, and the cover plate 6 is provided with a second air hole 1d at the position corresponding to the second chamber 1b. After the two-way pressure balance device is assembled on the top of the test box, the first air hole 1c communicates with the inside of the test box, and the second air hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com