Preparation device for silicon-based film negative plate of lithium battery

A silicon-based thin film and preparation device technology, which is applied in electrode manufacturing, battery electrodes, electrostatic spraying devices, etc., can solve problems such as unevenness of the silicon-based thin film on the surface of copper foil, and avoid lithium powder accumulation, capacity reduction, and aggregation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

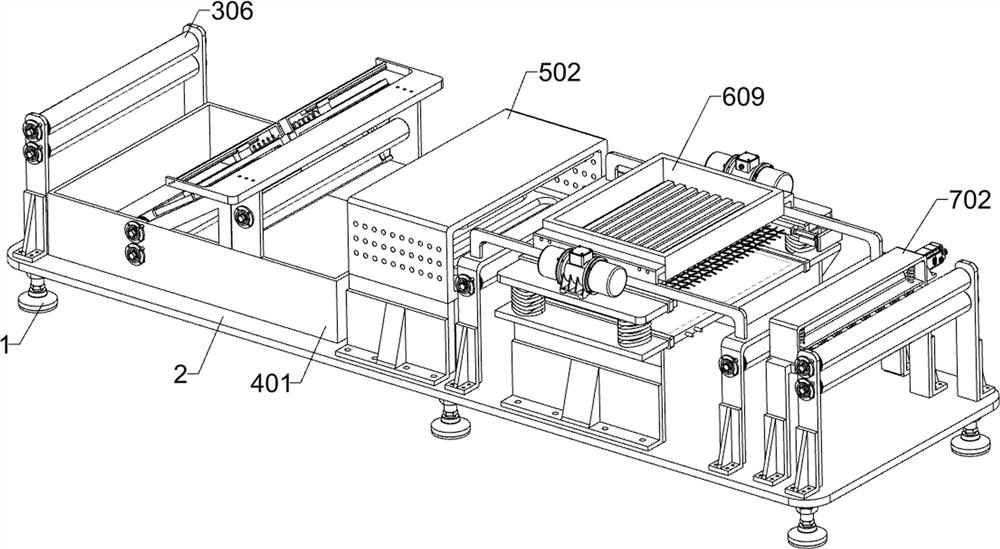

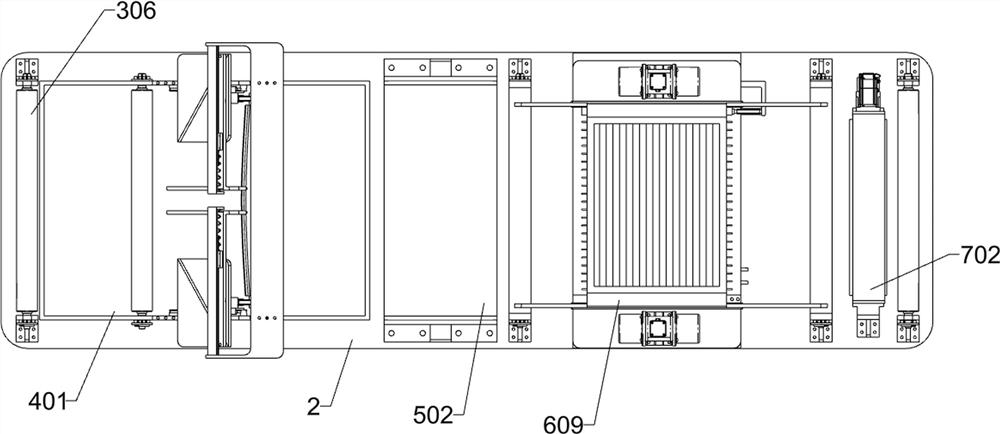

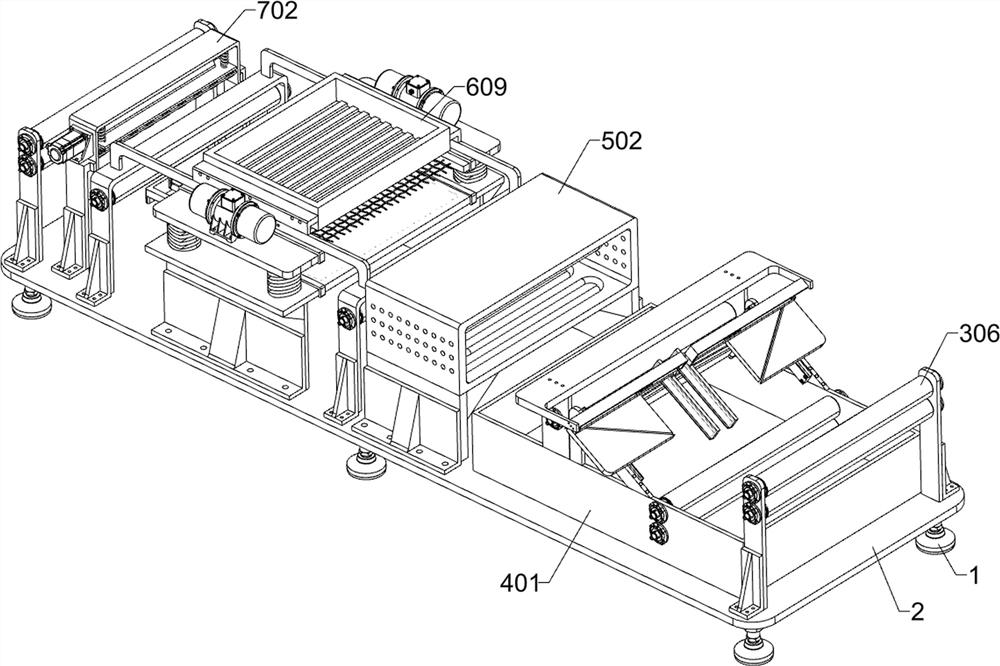

[0036] A lithium battery silicon-based thin film negative plate preparation device, such as Figure 1-3 As shown, it includes feet 1, a first mounting plate 2, a transmission unit, a flattening unit and a drying unit; the top of the six feet 1 is connected to the first mounting plate 2; the upper side of the first mounting plate 2 is connected to a transmission unit; the upper left part of the first mounting plate 2 is connected with a flattening unit; the upper middle part of the first mounting plate 2 is connected with a drying unit.

[0037] The transmission unit includes a first mounting frame 301, a second mounting frame 302, a third mounting frame 303, a fourth mounting frame 304, a first motorized guide roller 305, a second motorized guide roller 306, a third motorized guide roller 307, a Four motorized guide rollers 308, the fifth motorized guide roller 309 and the ninth motorized guide roller 3010; the upper left part of the first mounting plate 2 is fixedly connected...

Embodiment 2

[0046] On the basis of Example 1, such as figure 1 with Figure 10-17 As shown, it also includes a lithium supplementary powder unit; the upper right part of the first mounting plate 2 is connected with a lithium supplementary powder unit, and the lithium supplementary powder unit is connected with the transmission unit; the lithium supplementary powder unit includes a seventh mounting frame 601, a Two springs 602, the fifth mounting plate 603, the first vibration motor 604, the eighth mounting frame 605, the second electric slide rail 606, the second electric slider 607, the baffle plate 608, the lithium powder box 609, the second electric push rod 6010, the first insulating block 6011, the first screen fastening rod 6012, the insulating slide rail 6013, the second insulating block 6014, the straight plate electrode 6015, the third insulating block 6016, the second screen fastening rod 6017, the third L shape block 6018, screen electrode 6019, second vibrating motor 6020 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com