Novel variable-diameter pipeline rust removal robot

A robot and robot body technology, applied in the field of robots, can solve the problems of low efficiency of chemical rust removal, environmental pollution, low efficiency, etc., and achieve the effect of high rust removal efficiency, high mechanical efficiency, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further described below in conjunction with accompanying drawing.

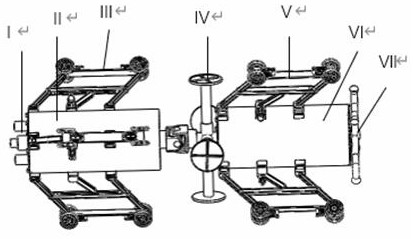

[0040] figure 1 The main design content of this design is a new type of variable-diameter pipeline derusting robot, including vision and lighting mechanism (Ⅰ), the first section of the robot (II), and the first section of variable-diameter wheel set mechanism (Ⅲ) , ultra-high pressure water injection mechanism (Ⅳ), the second variable-diameter wheel group mechanism (Ⅴ), the second section robot (Ⅵ), and the drying mechanism (Ⅶ). Purposes such as sports and rust removal.

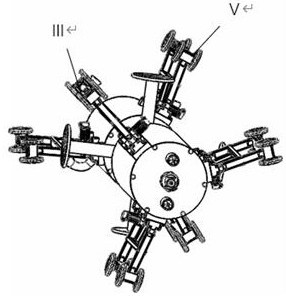

[0041] figure 2 It is the axial side view of the two-section variable-diameter pipeline robot. The adjacent wheel mechanisms of the first variable-diameter wheel mechanism (Ⅲ) and the second variable-diameter wheel mechanism (Ⅴ) are 120 degrees apart. , further improving the stability of the pipeline robot.

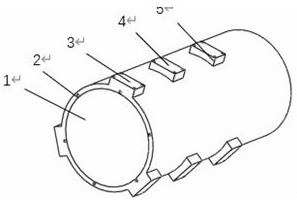

[0042] image 3 It is the main body 1 of the pipeline robot, on which bolt holes 2 and fixed bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com