Continuous liquid supply printing system and method for liquid metal 3D printing

A 3D printing and printing system technology, applied in the field of 3D printing, can solve the problems of 3D printing being blocked, affected, and the purity of liquid metal is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

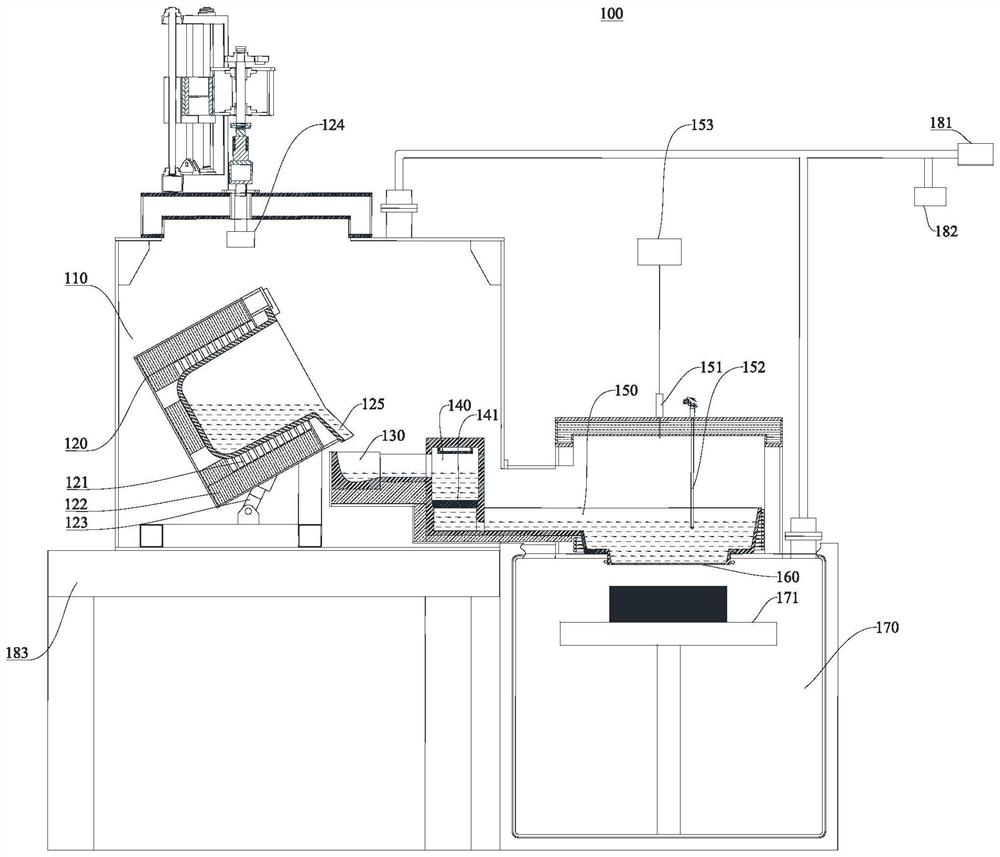

[0058] This embodiment provides a continuous liquid supply printing based on the continuous liquid supply printing system 100, which includes the following steps:

[0059] S1: The upper chamber 110 is evacuated by the vacuum pump 181, and the aluminum alloy is configured according to the composition ratio of 7150 aluminum alloy, that is, Si 0.12%, Fe 0.15%, Cu 1.9-2.5%, Mn 0.1%, Mg 2.0-2.7%, Cr 0.04%, Zn 5.9-6.9%, Zr 0.08-0.15, Ti 0.15, other impurities total 0.15%, put the massive or powdery material into the pouring crucible 120, turn on the switch of the heating coil 121, and heat the metal to 750 °C melts the metal.

[0060] S2: Start degassing treatment after the aluminum alloy is completely melted, turn on the rotary blower 124, and pass in argon gas for 30 minutes for degassing.

[0061] S3: Start the hydraulic control system 153 to tilt the pouring crucible 120, the molten metal flows from the pouring spout 125 into the melt receiving pool 130, and sequentially passes...

Embodiment 2

[0065] This embodiment provides a continuous liquid supply printing based on the continuous liquid supply printing system 100. Except that the step S4 of the liquid supply method is different from that in Embodiment 1, S1, S2, and S3 of the liquid supply system and the liquid supply method are the same as those in the embodiment. 1.

[0066] In this embodiment, the vacuum degree of the lower chamber 170 is 25kpa, the upper chamber 110 is argon, and the pressure difference is controlled at 35kpa.

Embodiment 3

[0068] This embodiment provides a continuous liquid supply printing based on the continuous liquid supply printing system 100. Except that the step S4 of the liquid supply method is different from that in Embodiment 1, S1, S2, and S3 of the liquid supply system and the liquid supply method are the same as those in the embodiment. 1.

[0069] In this embodiment, the lower chamber 170 is fed with argon at a pressure of 10 kpa, the upper chamber 110 is fed with argon at a pressure of 35 kpa, and the pressure difference is controlled at 10 kpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com