Process for machining oil groove part by using macro program

A technology for processing oil and macro programs, applied in the field of mechanical processing, can solve the problem that economical CNC lathes are not suitable for processing 8-figure or double 8-shaped closed oil grooves, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

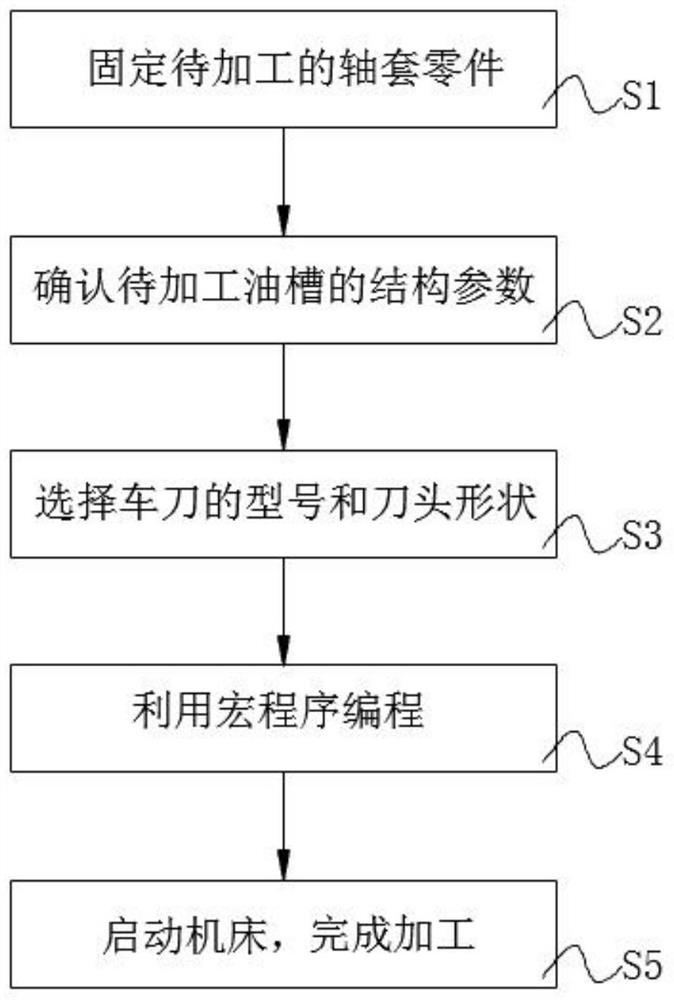

[0022] Such as figure 1 As shown, a process for machining oil tank parts using macro programs includes the following steps:

[0023] S1: Fix the shaft sleeve parts to be processed on the economical CNC lathe;

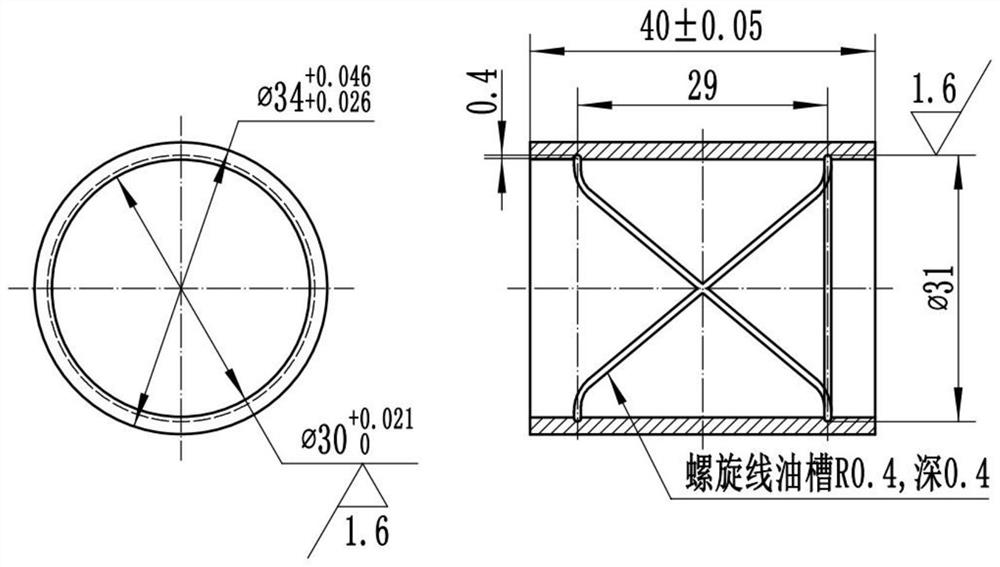

[0024] S2: if figure 2 As shown, confirm the structural parameters of the oil groove to be processed. The structural parameters include the cross-sectional shape, the processing diameter of the oil groove, the processing depth of the oil groove and the processing length of the oil groove;

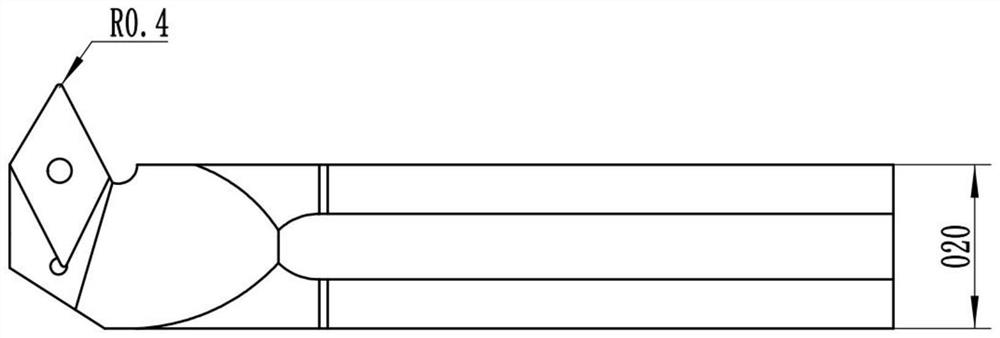

[0025] S3: if image 3 As shown, select the turning tool model and cutter head shape according to the cross-sectional shape of the oil groove in S2;

[0026] S4: if Figure 4 As shown, according to the processing diameter, processing depth and processing length of the oil groove in S2, the macro variable is used to program, and the method of oblique feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com