Manufacturing process for digital embossing effect of decorative plate, plate structure of decorative plate and preparation system of decorative plate

A technology for making crafts and decorative boards, which is applied in decorative arts, embossed ornaments, post-processing of printing, etc. It can solve the problems that patterns cannot correspond to consistent textures and are not clear, and achieve good decorative effects, good visual effects, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to the following implementation manners.

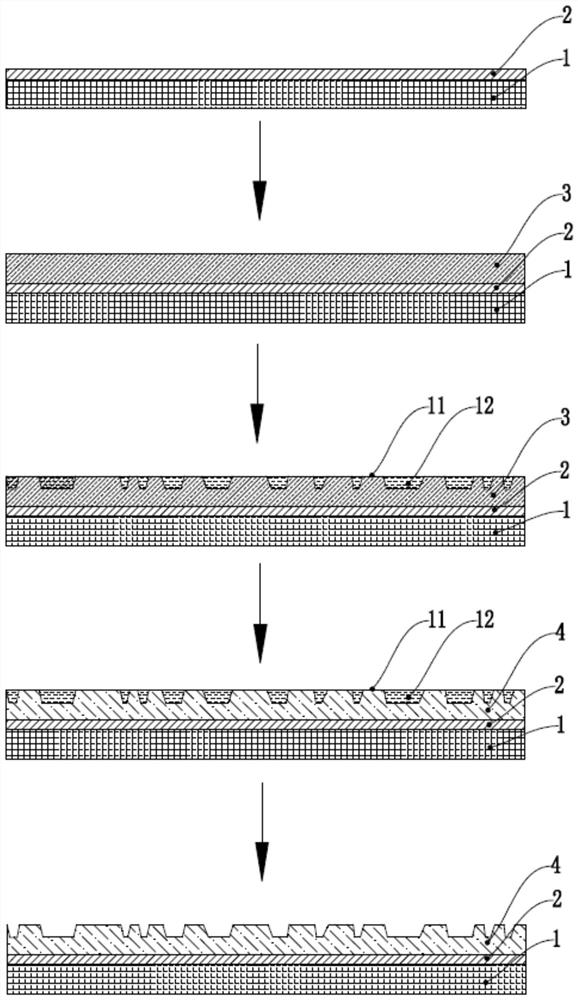

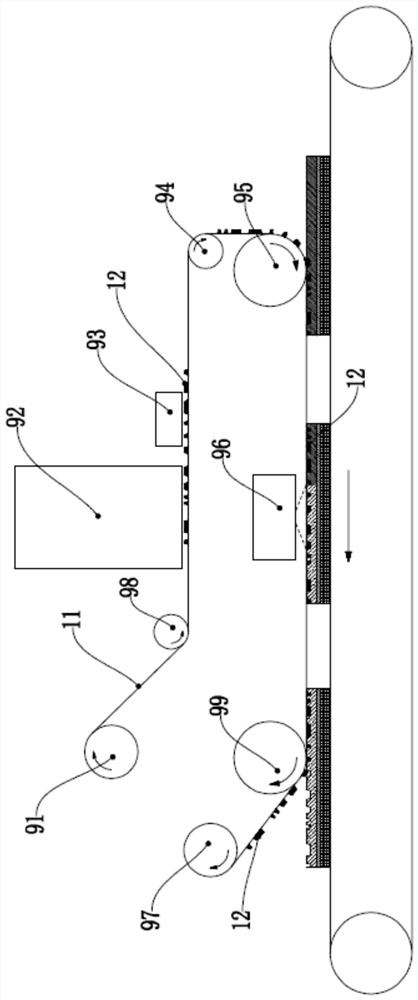

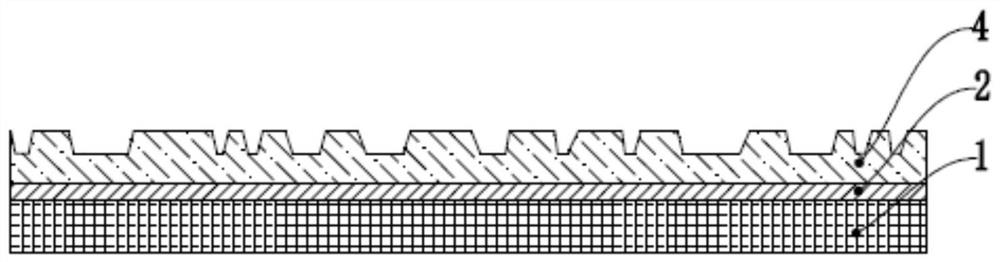

[0040] like Figure 1 to Figure 4 As shown, a manufacturing process of digital embossing effect on decorative boards, including the following steps:

[0041] Step A, inkjet printing and curing the pattern on the upper surface of the substrate 1 to obtain the pattern layer 2;

[0042]Step B, uniformly coating the UV coating liquid on the surface of the pattern layer 2 to obtain a liquid UV coating 3;

[0043] Step C, printing pattern embossment 12 with UV ink on the surface of transparent film 11, said pattern embossment 12 corresponding to the position where the pattern of said pattern layer 2 needs to be recessed, and then curing said UV ink;

[0044] Step D, laying the transparent film 11 on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Texture depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com