Full-automatic charging tray vacuum bag sealing and packaging equipment

A kind of packaging equipment, fully automatic technology, applied in packaging, packaging machine, transportation packaging, etc., can solve the problems of poor packaging quality, high cost, loose products, etc., achieve compact structure layout, improve bag opening efficiency, and improve packaging efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

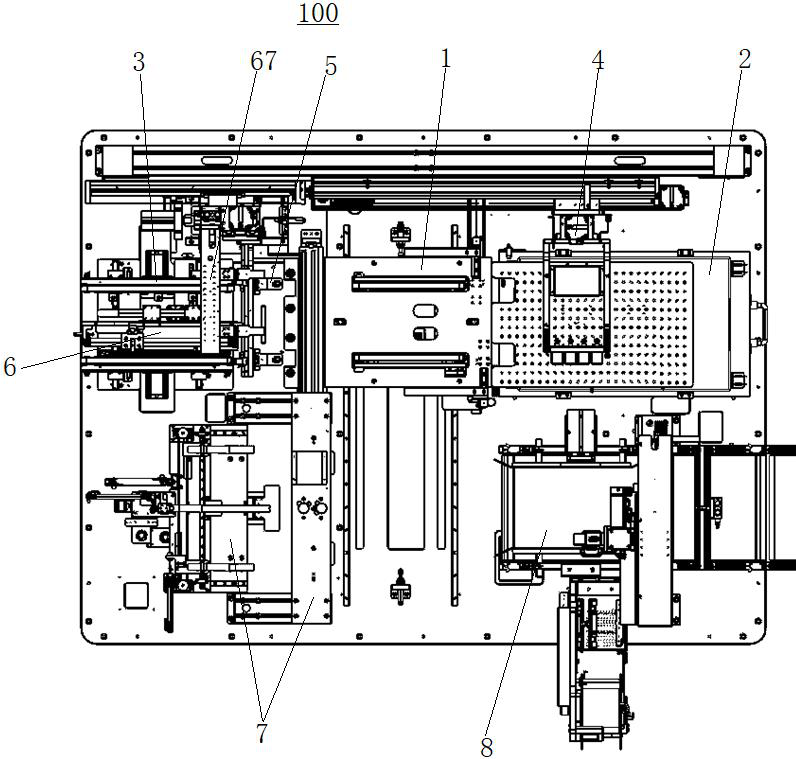

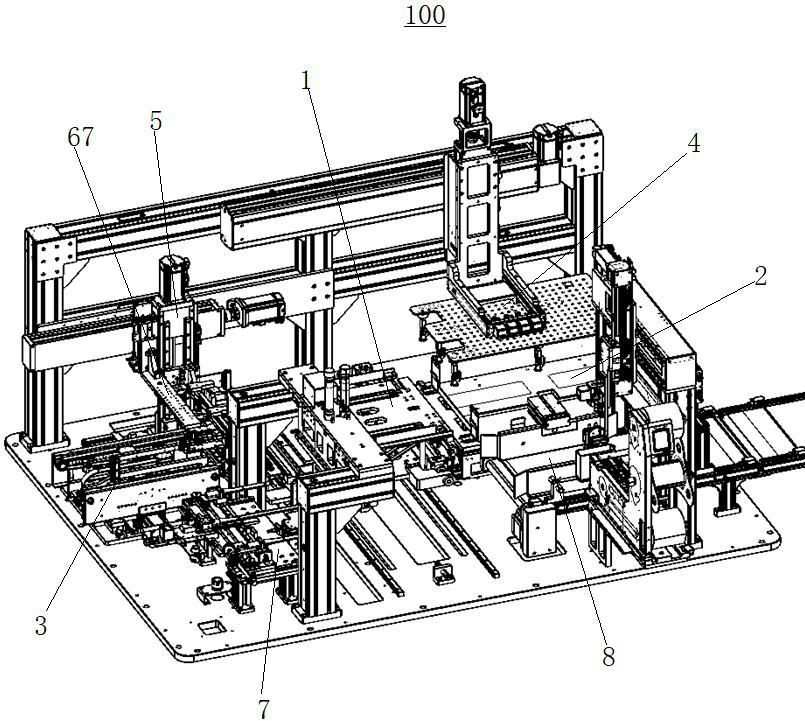

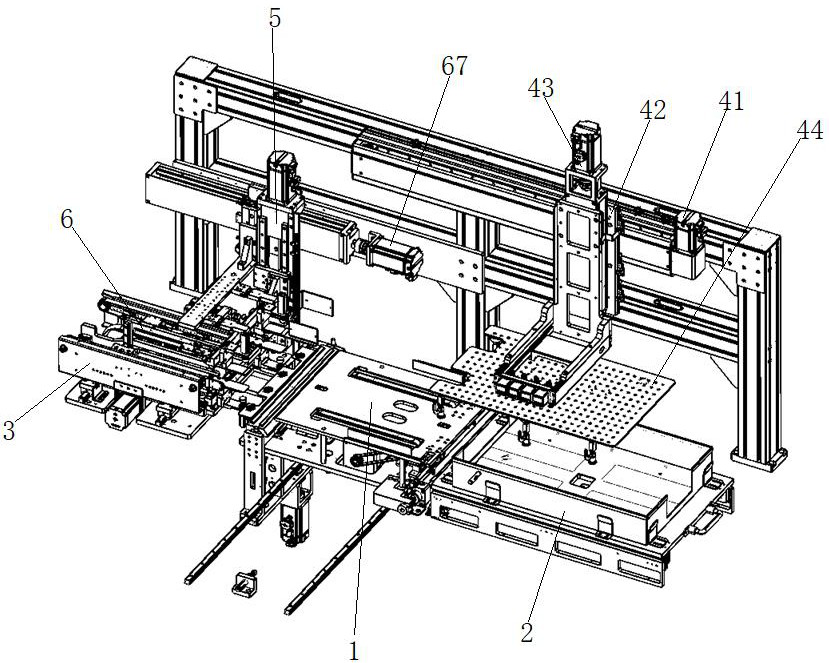

[0046] Please refer to Figure 1-Figure 16 , the present embodiment fully automatic tray vacuum bag sealing packaging equipment 100, which includes a packaging bag transfer unit 1 that moves between the bag filling station and the bag sealing station, and is relatively arranged on both sides of the packaging bag transfer unit 1 And the packaging bag silo 2 corresponding to the position of the bagging station and the tray conveying unit 3, the packaging bag handling unit 4 that takes out the packaging bag from the packaging bag silo 2 and places it on the packaging bag transfer unit 1, The bag opening unit 5 that opens the packaging bag on the packaging bag transfer unit 1, the material tray pushing unit 6 that pushes the tray from the tray conveying unit 3 into the packaging bag, and is relatively arranged on the packaging bag transfer unit. The bag sealing vacuum unit 7 and the labeling receiving unit 8 on both sides of the loading unit 1 and corresponding to the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com