Fault double-layer redundancy monitoring method, early warning method and system

A redundant monitoring and double-layer technology, applied in the direction of load hanging components, safety devices, cranes, etc., can solve problems such as inability to hoist, provide safety margin, and difficult to identify and discover, and achieve timely and reliable fault and fault early warning , the effect of avoiding overturning accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

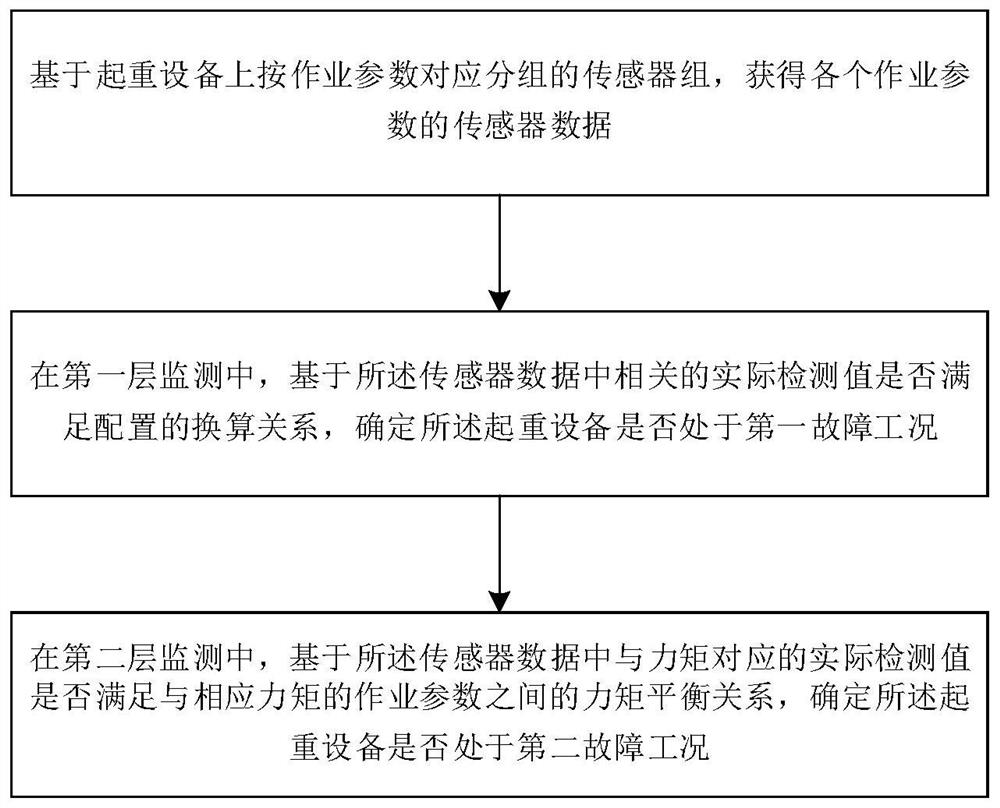

[0097] The embodiment of the present invention provides a fault double-layer redundancy monitoring method, such as figure 1 , the fault double-layer redundancy monitoring method may include:

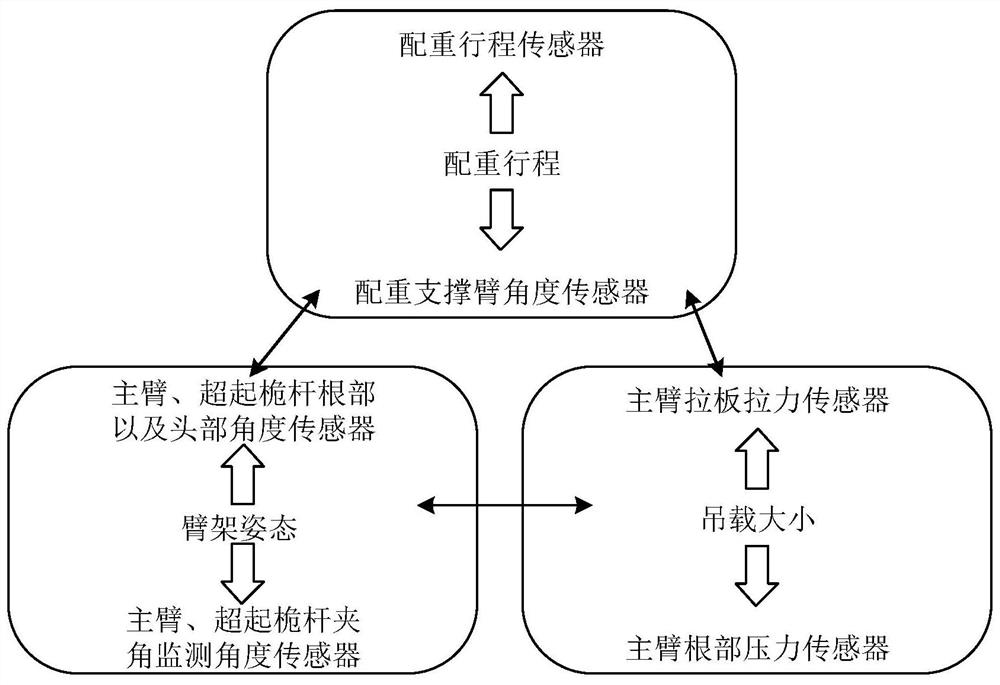

[0098] Based on the sensor groups grouped according to the operation parameters on the lifting equipment, the sensor data of each operation parameter is obtained;

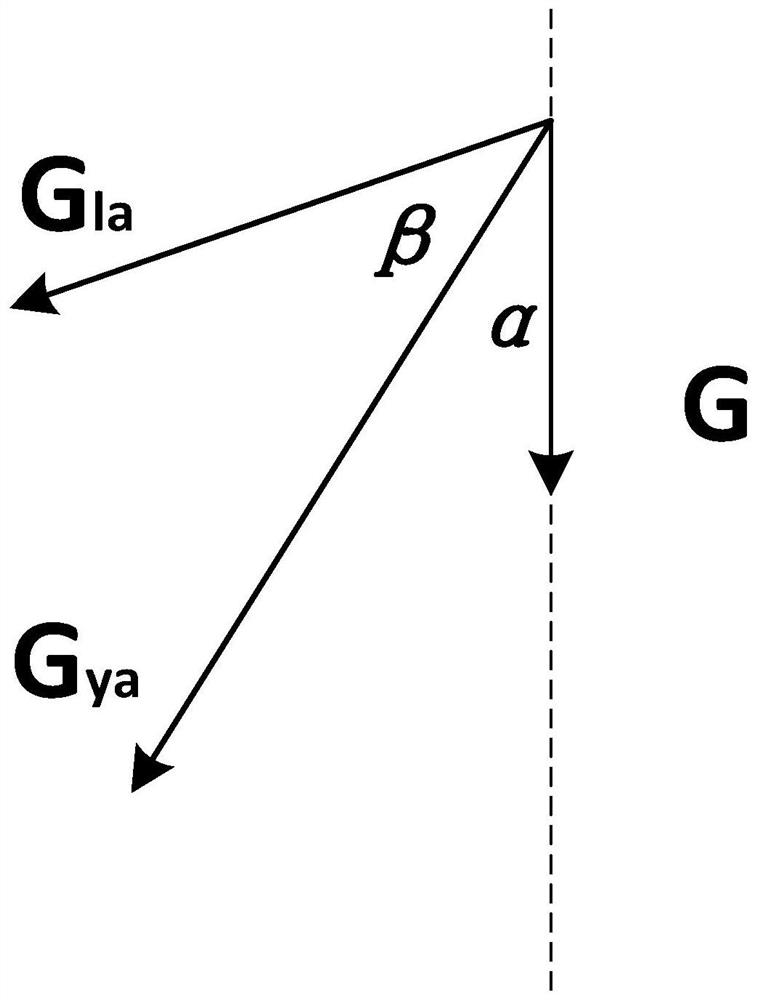

[0099] In the first layer of monitoring, it is determined whether the hoisting equipment is in a first fault condition based on whether the relevant actual detected values in the sensor data satisfy a configured conversion relationship, wherein the conversion relationship includes a The geometric conversion relationship between the operating parameters corresponding to the actual detected value;

[0100] In the second layer of monitoring, based on whether the actual detected value corresponding to the torque in the sensor data satisfies the torque balance relationship with the operating parameters of the corresponding torq...

Embodiment 2

[0185] The embodiment of the present invention and Embodiment 1 belong to the same inventive concept. The embodiment of the present invention provides a double-layer redundant early warning system for faults. Redundant early warning systems can include:

[0186] an obtaining module, used for obtaining sensor data of each working parameter based on the sensor groups corresponding to the working parameters on the lifting equipment;

[0187] The first-layer monitoring module is configured to, in the first-layer monitoring, determine whether the hoisting equipment is in the first fault condition based on whether the relevant actual detected values in the sensor data satisfy the configured conversion relationship, wherein all the The conversion relationship includes the geometric conversion relationship between the operating parameters corresponding to the relevant actual detection values;

[0188] The second-layer monitoring module is configured to, in the second-layer monitori...

Embodiment 3

[0232] The embodiments of the present invention belong to the same inventive concept as Embodiments 1 and 2, and the embodiments of the present invention provide electronic equipment, construction machinery, and computer-readable storage media.

[0233] Electronic equipment is intended to represent various forms of equipment with instruction processing and computing capabilities, such as computers, industrial computers, and servers. Processors and memories can be implemented in the form of a system-on-chip (SoC or MCU) or directly The assembly method of the circuit board to which the interface is connected. The memory stores instructions that can be executed by at least one processor, and the at least one processor implements the method in the foregoing embodiment 1 by executing the instructions stored in the memory, and the electronic device can be used to form the monitoring of the lifting device in the embodiment 1. Network, in some advantageous embodiments, electronic devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com