Low-loss fabric printing and dyeing process

A printing and dyeing process and low-loss technology, which is applied in the field of fabric processing and can solve problems such as inability to detect fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

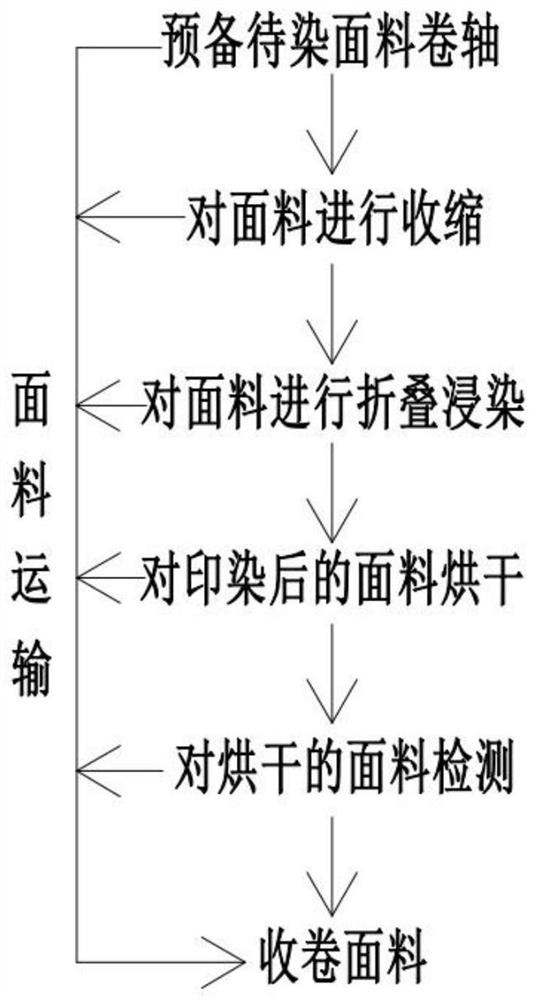

[0023] refer to figure 1 , detailing the implementation process of printing and dyeing fabrics:

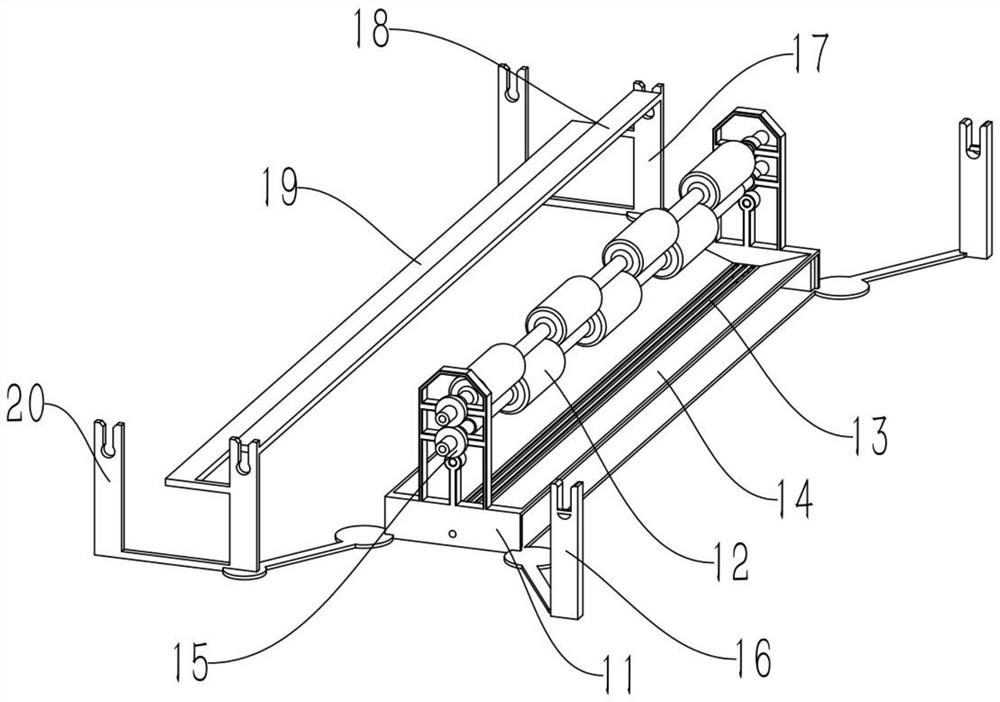

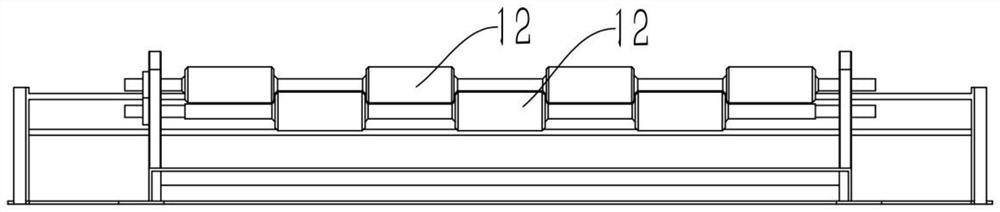

[0024] The low-loss fabric printing and dyeing process relates to a low-loss fabric printing and dyeing device, the device includes a box frame 11, two printing and dyeing shafts 12 are rotatably connected to the box frame 11, and a plurality of discharge holes are arranged on the two printing and dyeing shafts 12 , to ensure that the dye can flow out from multiple discharge holes, and the fabric passing through the middle is printed and dyed through the rotation of the two printing and dyeing shaft wheels 12. Both ends of the two printing and dyeing shaft wheels 12 are fixedly connected with feed pipes 21, and the two Two feeding pipes 21 are mainly responsible for supplying dyestuffs to the two printing and dyeing shaft wheels 12 to ensure sufficient dyestuff in the two printing and dyeing shaft wheels 12. The two feeding pipes 21 are fixedly connected and communicated with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com