Motor stator insulation sheet closing-up assembling device

An assembly device and motor stator technology, applied in laying solid insulation, manufacturing stator/rotor body, etc., can solve the problems that the products cannot be automated, the quality cannot be effectively guaranteed, and the qualified rate of finished products is low, so as to improve production Efficiency and production quality, assembly stability, effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

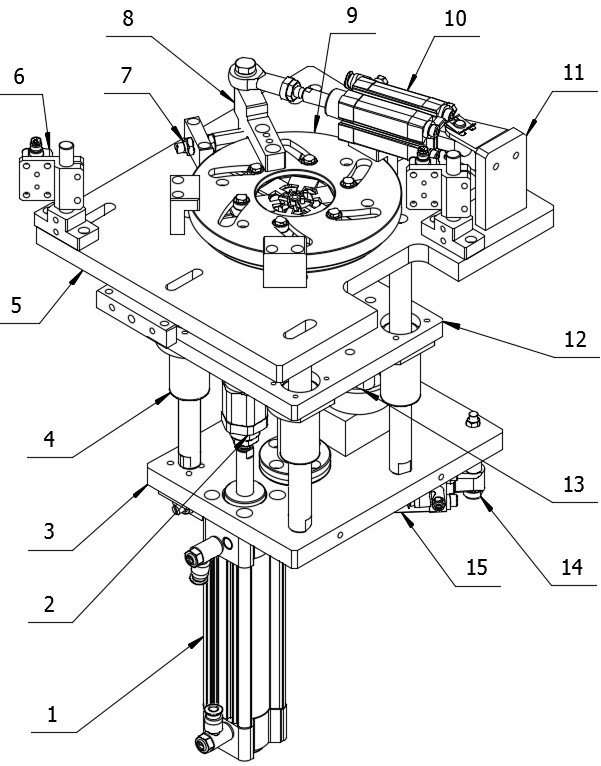

[0014] In order to make the objectives, technical solutions and advantages of the present invention more clear, the following will describe the current specific implementation in detail in conjunction with the accompanying drawings and examples. The appended claims and accompanying drawings are for the structure and other aspects and features of the present invention. and advantages will be more readily understood, wherein like reference numerals are used to designate like parts. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the protection scope of the present invention.

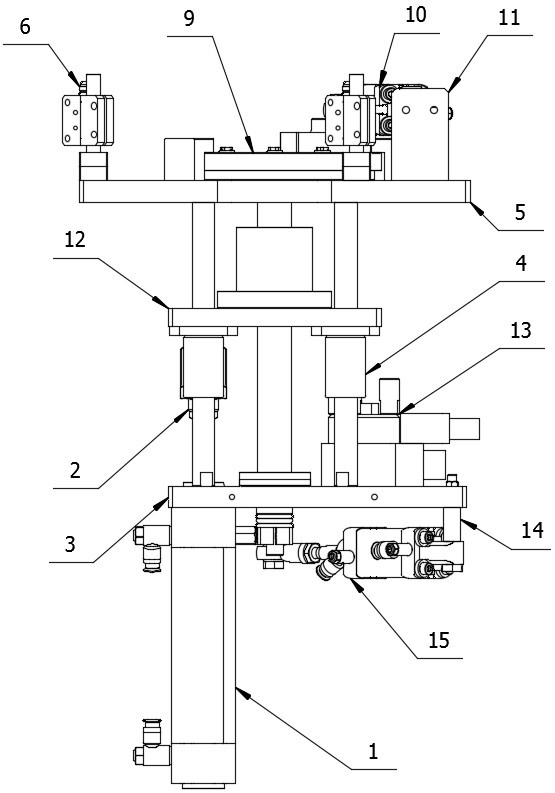

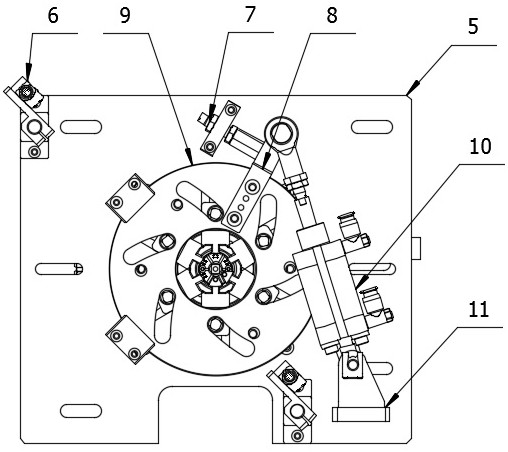

[0015] see figure 1 , figure 2 and image 3 According to an embodiment of the present invention, a motor stator insulation sheet closing assembly device includes a mounting plate 5 and a fixing plate 3 mounted on the mounting plate 5 through a rod guide sleeve assembly 4, and a push cylinder 1 is mounted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com